How Custom Sheet Metal Fabrication Transforms Industrial Applications

- Share

- Issue Time

- Nov 11,2025

Summary

Custom sheet metal fabrication is a cornerstone of modern industrial manufacturing, enabling the creation of precise, durable, and cost-effective components essential across diverse sectors. This process transforms raw materials into highly specialized parts that off-the-shelf products cannot match, driving innovation in fields such as automotive, aerospace, medical, and renewable energy.

Key benefits include unmatched precision, ensuring parts fit perfectly into complex assemblies and minimizi

When I look at the world around me, from the cars we drive to the buildings we inhabit, I see the subtle yet profound impact of custom sheet metal fabrication. It’s more than just shaping metal; it’s about transforming raw materials into intricate, high-performing components that are essential across countless industries. This process allows engineers and designers to bring their most complex visions to life, creating tailored solutions that off-the-shelf products simply can’t match.

Custom sheet metal fabrication is revolutionizing industrial applications by offering unparalleled precision, durability, and cost-effectiveness. It’s a dynamic field constantly evolving with technological advancements, ensuring that industries can meet diverse and demanding specifications. Join me as I explore how this vital manufacturing process is shaping the future of various sectors and why it’s become indispensable for innovation and progress.

Key Takeaways

- Precision and Fit: Custom fabrication allows for the creation of parts with exceptionally tight tolerances, ensuring they meet exact project specifications for a perfect fit and optimal function. This precision minimizes on-site adjustments and reduces material waste.

- Enhanced Durability: By selecting high-quality, application-specific materials like stainless steel or aluminum and employing advanced techniques, custom fabricated parts are built to withstand harsh industrial environments, leading to a longer lifespan and reduced maintenance.

- Cost-Effectiveness: While seemingly more expensive upfront, custom fabrication proves cost-effective in the long run by optimizing material usage, minimizing waste through processes like nesting, and reducing the need for costly rework and frequent replacements.

- Technological Advancements: Modern fabrication leverages technologies like CNC laser cutting, robotic bending, and AI-powered quality control to achieve new levels of precision, efficiency, and complexity in component manufacturing.

- Broad Industrial Impact: Custom sheet metal parts are critical across numerous sectors, including automotive and aerospace for lightweight components, medical for sterile and precise devices, and renewable energy for sustainable infrastructure.

The Foundational Benefits of Custom Sheet Metal Fabrication

Custom Sheet Metal Fabrication is essential in modern industrial manufacturing, serving as the backbone for creating specialized components that standard parts simply cannot match. This highly specialized process involves the precise cutting, bending, and assembling of metal sheets to meet unique project requirements. The core advantages it offers—precision, durability, and cost-efficiency—make it a cornerstone of innovation and productivity across a vast range of sectors, from aerospace to construction.

Unmatched Precision and the Perfect Fit with Sheet Metal Fabrication

In industrial applications, precision is not just a goal; it's a fundamental requirement for safety, efficiency, and performance. Custom fabrication excels by producing parts with exceptional accuracy, ensuring they integrate flawlessly into larger assemblies. This perfect fit is crucial in complex machinery and structural systems where even minor deviations can lead to significant operational issues.

Achieving Exact Specifications and Reduced Waste in Sheet Metal Fabrication

One of the foremost benefits of custom fabrication is its ability to produce components that adhere to exact specifications. Tolerances, which define the permissible variations in a part's dimensions, are critical for ensuring proper fit and function. In sheet metal fabrication, these tolerances can be incredibly tight, often measured in fractions of a millimeter, to guarantee that parts are interchangeable and assemble correctly. Modern fabrication shops utilize advanced machinery, such as CNC punch presses and lasers, that can reliably hold tolerances down to +/- 0.005 inches on features located on the same surface.

This level of precision has a direct and positive impact on sustainability and cost. By manufacturing parts to exact dimensions from the start, the need for on-site modifications and adjustments is virtually eliminated, saving both time and labor. More importantly, advanced planning and technology significantly reduce material waste. Techniques like "nesting," where computer-aided design (CAD) software optimally arranges parts on a single sheet of metal, maximize material utilization and drastically cut down on scrap. This not only lowers material costs but also reduces the environmental footprint of the manufacturing process, aligning with modern lean manufacturing principles.

Enhanced Compatibility and Performance with Custom Sheet Metal Fabrication

When components are manufactured to generalized standards, they may not fit optimally with other specific hardware, leading to compatibility issues. Custom sheet metal fabrication resolves this by creating parts designed to be perfectly compatible with the specific machinery or system they will be part of. This customized fit is essential for achieving peak performance. For example, a custom-designed tray for a medical sanitation chamber, built to the exact internal dimensions of the machine, maximizes the number of parts that can be processed in each load, thereby increasing overall process efficiency.

This enhanced compatibility directly translates to improved performance and reliability. Custom parts ensure seamless integration, which is critical in applications involving complex assemblies like automotive transmissions or aerospace components where parts must function perfectly together under varying conditions. Furthermore, the ability to reverse-engineer and fabricate obsolete parts for older but still reliable machinery is another significant advantage. This capability allows businesses to maintain and extend the life of valuable equipment instead of undertaking costly replacements. By ensuring every component is a perfect match, custom fabrication enhances the functionality, efficiency, and longevity of the entire system.

Durability and Longevity Through Advanced Sheet Metal Fabrication Techniques

Industrial components are often subjected to harsh conditions, including extreme temperatures, corrosive chemicals, and significant physical stress. Custom sheet metal fabrication addresses the critical need for durability by allowing for the selection of ideal materials and the application of advanced manufacturing techniques to create products that are built to last. This focus on longevity results in less frequent need for replacements, reduced maintenance costs, and a lower total cost of ownership over the product's lifecycle.

Selecting Optimal Materials for Robust Sheet Metal Fabrication

A key advantage of the custom fabrication process is the freedom to choose the perfect material for any given application. Unlike stock products made to a general standard, custom components can be crafted from specific metal alloys chosen for their unique properties. This strategic material selection ensures that the final product can withstand the specific environmental and operational stresses it will face.

Common materials and their applications include:

- Stainless Steel: Renowned for its superior strength and exceptional corrosion resistance, stainless steel is an ideal choice for equipment used in food processing, pharmaceutical, and chemical industries where hygiene and resistance to rust are paramount.

- Aluminum: This material offers an excellent combination of being lightweight yet strong, making it a popular choice in the aerospace and automotive industries where reducing weight is critical for fuel efficiency and performance.

- Titanium Alloys: For the most demanding applications, titanium provides an outstanding strength-to-weight ratio and can endure extreme temperatures and highly corrosive environments, making it suitable for aerospace and high-performance machinery.

- Carbon Steel: Known for its hardness and durability, carbon steel is often used for structural components and machinery parts that require high strength.

By carefully selecting the right grade of metal, such as using Grade 316 stainless steel for applications involving saltwater exposure, fabricators can dramatically extend the useful life of a component.

Building Products That Endure with Expert Sheet Metal Fabrication

Expert Sheet Metal Fabrication goes beyond just cutting and shaping metal; it involves designing and constructing parts that are inherently durable. The process allows for the creation of components that are not only tailored to fit but also engineered to endure rigorous industrial use. The superior design and fit achieved through customization lead to a longer useful life compared to prefabricated parts.

Furthermore, various finishing and surface treatment techniques can be applied to enhance durability even more. Processes like powder coating or galvanizing add a protective layer that improves resistance to corrosion, abrasion, and weathering, ensuring long-lasting performance even in outdoor or chemically aggressive environments. Mechanical fasteners such as rivets and rivnuts can also be used in place of welding to enhance load-bearing capabilities in thin sheet metal parts and allow for disassembly and reassembly, which is impossible for welded components. This thorough approach, from material selection to final finishing, ensures that custom-fabricated products provide reliable, long-term service.

Cost-Effectiveness and Efficiency in Sheet Metal Fabrication

While custom fabrication might seem to have a higher initial cost compared to buying off-the-shelf parts, it often proves to be a more cost-effective solution in the long run. The process is designed to optimize material use, streamline production, and create durable parts that reduce long-term expenses related to maintenance and replacement. By focusing on efficiency at every stage, custom fabrication delivers significant financial benefits over the entire project lifecycle.

Minimizing Material Waste and Production Costs in Sheet Metal Fabrication

A primary driver of cost-effectiveness in custom fabrication is the significant reduction in material waste. In traditional manufacturing, it's common for contractors to purchase more material than needed to avoid project delays, often leading to excess scrap that is discarded. Custom fabrication tackles this issue head-on through careful planning and advanced technology.

Advanced software is used to create optimal layouts for parts on a metal sheet, a technique known as nesting. This process minimizes the space between components, drastically reducing the amount of leftover material or scrap. Moreover, the high precision of technologies like laser cutting means cuts are clean and exact, preventing costly errors that would otherwise result in wasted material. Any remaining scrap metal is often managed effectively, with smaller offcuts being repurposed for other components or sent to recycling facilities to recover costs. By producing parts to exact specifications, manufacturers also eliminate the need for costly on-site modifications, further reducing expenses.

Streamlining Processes and Improving Throughput with Custom Sheet Metal Fabrication

Custom fabrication enhances manufacturing efficiency by streamlining production workflows and increasing throughput. By designing components that are perfectly compatible with existing systems and processes, assembly becomes faster and less prone to errors. This optimized workflow reduces lead times and allows for a more agile manufacturing process that can quickly respond to client demands.

Lean manufacturing principles are often at the core of modern fabrication shops. These principles focus on eliminating waste in all forms, including redundant steps, unnecessary material movement, and bottlenecks in the production line. Techniques such as creating parts that can be used across multiple processes without needing to be transferred to different containers can save valuable time. For instance, saving just a few minutes on each transfer in a multi-stage process can add up to significant productivity gains. The combination of custom-designed parts and efficient, lean processes not only speeds up production but also improves the overall quality and consistency of the final products.

Key Processes and Innovations in Modern Sheet Metal Fabrication

The world of Sheet Metal Fabrication is in a constant state of evolution, driven by technological breakthroughs that enhance precision, speed, and capability. From advanced cutting methods that create intricate shapes with minimal waste to automated systems that operate with robotic consistency, these innovations are redefining what is possible in manufacturing. The integration of these modern processes allows for the creation of complex, high-quality components that were once considered unachievable with traditional methods.

Advanced Cutting Technologies Revolutionizing Sheet Metal Fabrication

Cutting is the foundational first step in most fabrication projects, and modern technologies have transformed it into a science of precision. Today's cutting tools are faster, more accurate, and more versatile than ever, enabling fabricators to work with a wide range of materials and create designs of incredible complexity.

The Precision of Laser Cutting in Sheet Metal Fabrication

Laser cutting has become a cornerstone of the fabrication industry, prized for its exceptional precision and speed. This technology uses a high-powered, focused laser beam to melt, burn, or vaporize material, resulting in clean edges and remarkably intricate cuts. One of its chief advantages is the minimal heat-affected zone, which means the properties of the metal surrounding the cut are largely unaltered. Fiber lasers, in particular, have become a gold standard for their efficiency and ability to cut reflective metals like aluminum and copper.

Laser cutters are ideal for thin to medium-thick materials and can achieve incredibly tight tolerances, making them perfect for producing complex parts with smooth finishes that require little to no post-processing. The process is not only fast, especially for thin-gauge sheet metal, but also highly efficient in terms of material use, further contributing to its cost-effectiveness.

The primary metal cutting technologies each have distinct advantages:

- Laser Cutting: Offers the highest precision and smoothest finish, ideal for intricate designs on thin to medium-thick materials.

- Plasma Cutting: Best for cutting thick, electrically conductive metals like steel and aluminum quickly and cost-effectively, though the edges may be rougher.

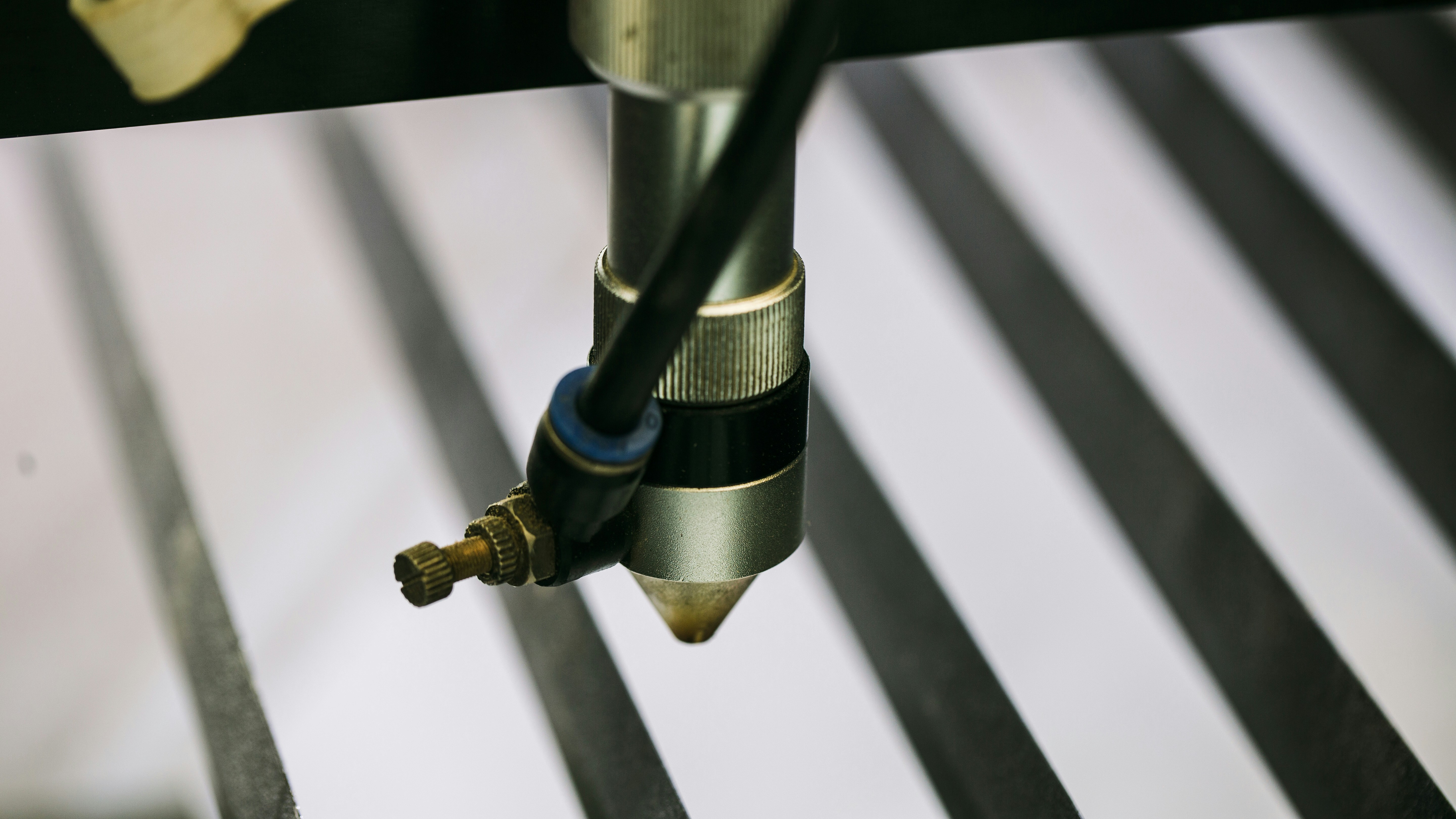

- Waterjet Cutting: Uses a high-pressure stream of water with abrasives to cut almost any material without generating heat, making it perfect for heat-sensitive materials or when avoiding thermal distortion is critical.

| Cutting Technology | Best For | Precision | Speed | Key Advantage |

|---|---|---|---|---|

| Laser Cutting | Thin to medium metals, intricate designs | Very High (±0.002″) | Very fast on thin sheets | Unmatched precision and clean edges. |

| Plasma Cutting | Thick conductive metals (steel, aluminum) | Moderate (±0.020″) | Fastest on thick metals | Speed and cost-effectiveness for thick plates. |

| Waterjet Cutting | Any material, heat-sensitive applications | High | Slower | No heat-affected zone, versatile material capability. |

New Horizons in CNC Punching for Sheet Metal Fabrication

CNC (Computer Numerical Control) punching continues to be a vital process for creating holes, notches, and other features in sheet metal at high speeds. Modern innovations have significantly enhanced the productivity and capabilities of CNC turret punch presses. Servo-electric motors have replaced older hydraulic systems, offering superior speed, power control, and energy efficiency. This allows machines to achieve extremely high hit rates while reducing operational costs.

Recent advancements include user-friendly programming systems that simplify operation and reduce the need for highly skilled workers. Combination machines that integrate different tools, such as a laser cutter and a punch press, save space and eliminate the need to move a part between machines. Furthermore, "skeleton-free" processing technology optimizes sheet utilization by punching out the scrap frame, which can increase material yields by an average of 10%. This automated process, controlled by smart software, also helps in separating parts from scrap, streamlining the workflow.

Forming and Shaping Techniques in Sheet Metal Fabrication

After cutting, the flat metal sheet must be formed into its three-dimensional shape. This stage involves a variety of techniques that bend, stretch, and roll the metal into the desired geometry. The sophistication of these methods determines the complexity and structural integrity of the final component. These processes rely on the metal's plasticity to deform it without compromising its underlying structure.

Mastering Sheet Metal Bending for Complex Geometries

Bending is one of the most common forming processes, used to create angles and shapes like V-bends, U-bends, and channels. The primary tool for this is the press brake, which uses a punch and a die to deform the sheet metal. CNC press brakes have revolutionized this process, allowing for automated, multi-bend operations with incredible precision and repeatability. This automation is particularly useful for low- to medium-volume production runs where creating costly stamping tools isn't justified.

There are several key bending techniques:

- Air Bending: The punch presses the metal into the die without it touching the bottom, allowing for flexibility in creating various angles with lower force.

- Bottoming: The sheet is pressed fully into the die, resulting in a more accurate and repeatable bend with less springback—the tendency of metal to return to its original shape.

- Coining: A high-force method where the punch and die make full contact, creating very sharp, precise angles with minimal springback.

For creating more intricate shapes, advanced techniques like rotary bending for tight radii and elastomer bending, which uses a soft cushion to prevent surface marks on sensitive materials, are employed.

The Role of Rolling and Welding in Sheet Metal Fabrication

Rolling is a forming process used to reduce the thickness of a metal sheet or to create curved and cylindrical shapes. In plate rolling, a long strip of metal passes through a series of rollers that progressively bend it until the desired cross-section is achieved. This method is ideal for producing parts with long lengths or in large quantities, such as roofing panels, pipes, and structural beams. The precision of the rolling machine is crucial, as poor execution can lead to defects like cracks or warping that compromise the structural integrity of the final product.

Welding is a fundamental joining process that fuses separate metal pieces together, typically by using high heat to melt the parts and allowing them to cool into a strong, permanent bond. It is essential for creating complex assemblies that cannot be formed from a single piece of sheet metal. Robotic welding has become a key technology in modern fabrication, as robots can perform precise and consistent welds continuously without fatigue. This automation not only increases throughput but also enhances the quality and structural integrity of the welded joints, which is critical in load-bearing applications.

The Impact of Automation and AI on Sheet Metal Fabrication

Automation and Artificial Intelligence (AI) are spearheading a new industrial revolution in sheet metal fabrication. These technologies are moving beyond simple repetitive tasks to take on complex roles in design, process optimization, and quality control. By integrating AI and robotics, manufacturers can achieve unprecedented levels of efficiency, precision, and flexibility, paving the way for the "smart factory" of the future.

Robotics and Automated Systems in Sheet Metal Fabrication

Robotics and automation are transforming the factory floor by handling tasks that are repetitive, dangerous, or require immense precision. Automated systems, from loaders and unloaders that continuously feed machines to robotic arms that perform cutting, bending, and welding, have dramatically increased production speed and consistency. Robots can operate 24/7 without fatigue, reducing lead times and allowing manufacturers to scale production up or down based on demand.

One key advantage of robotics is the improvement in accuracy and the reduction of human error. Robots can perform tasks like welding and bending with unmatched consistency, ensuring every product meets the exact specifications. This not only enhances product quality but also reduces material waste from mistakes. Furthermore, automation improves workplace safety by taking over physically demanding or hazardous jobs, allowing human workers to focus on more complex, value-added tasks.

AI-Powered Design and Quality Control in Sheet Metal Fabrication

Artificial Intelligence is making fabrication processes smarter and more predictive. In the design phase, AI-powered generative design software can automatically create thousands of design options based on specified constraints like weight, material, and strength. This helps engineers discover optimized geometries that are lighter and stronger than what a human designer might conceive. AI algorithms also optimize nesting layouts to reduce material usage by as much as 15%.

In quality control, AI-driven computer vision systems are a game-changer. These systems use high-resolution cameras to inspect parts in real-time, detecting defects like burrs, warping, or incorrect bends that might be invisible to the human eye. By comparing the finished part to its digital model, AI can instantly flag any deviations, potentially reducing defect rates by a significant margin. AI also plays a crucial role in predictive maintenance, where it analyzes data from machine sensors to anticipate equipment failures before they happen, minimizing costly downtime and ensuring consistent production quality. Industry forecasts suggest that by 2035, over 70% of advanced fabrication facilities will utilize AI-driven monitoring and control systems.

Diverse Industrial Applications of Sheet Metal Fabrication

The versatility of custom Sheet Metal Fabrication makes it an indispensable process across a vast spectrum of industries. Its ability to produce strong, lightweight, and highly precise components has positioned it as a cornerstone of modern manufacturing. From the cars we drive to the life-saving medical devices in hospitals, the impact of custom-fabricated metal parts is everywhere, enabling innovation and driving progress in countless fields.

Sheet Metal Fabrication in the Automotive and Aerospace Industries

In industries where performance, safety, and efficiency are paramount, sheet metal fabrication provides critical solutions. Both the automotive and aerospace sectors rely heavily on custom components that offer an optimal balance of strength and weight, and fabrication delivers on these demanding requirements.

Lightweight and Durable Components Through Sheet Metal Fabrication

Weight reduction is a key objective in both automotive and aerospace design. In the automotive sector, lighter vehicles consume less fuel and produce fewer emissions, while in aerospace, reduced weight improves payload capacity and flight range. Sheet metal fabrication is essential for achieving these goals by creating parts from materials like aluminum and high-strength steel alloys, which offer an excellent strength-to-weight ratio. These materials allow for the creation of components that are both thin and light, yet possess the structural integrity needed to withstand significant stress.

The applications are extensive. In automobiles, lightweight yet strong parts like body panels, doors, hoods, and chassis components are fabricated from sheet metal. In the aerospace industry, sheet metal is used for aircraft fuselages, wings, engine components, and various structural supports. The process is so precise that it can create complex aerodynamic shapes that reduce drag and improve performance. Materials such as titanium and specialized alloys, known for their ability to withstand extreme temperatures and corrosion, are also frequently used, ensuring the safety and reliability critical for flight.

The Critical Role of Sheet Metal Fabrication in Medical Devices and Electronics

Precision, hygiene, and reliability are non-negotiable in the medical and electronics fields. Custom sheet metal fabrication provides the necessary accuracy and material properties to produce components that meet the stringent standards of these highly regulated industries.

Ensuring Sterility and Accuracy with Sheet Metal Fabrication for Healthcare

In the medical industry, equipment must be durable, easy to sterilize, and completely reliable. Sheet metal fabrication is used to create a wide array of medical products, from surgical instruments like scalpels and forceps to larger equipment like operating tables, hospital beds, and enclosures for diagnostic machinery. Stainless steel, particularly grades like 316, is a common choice due to its exceptional resistance to corrosion and its ability to withstand harsh sterilization processes like autoclaving without degrading.

The surfaces of medical devices must be smooth and non-porous to prevent bacterial growth and ensure they can be thoroughly cleaned. Fabrication techniques, including specialized surface finishes like electropolishing, create ultra-smooth, mirror-like surfaces that resist contamination. This meticulous attention to detail is vital for patient safety and is a key reason why custom fabrication is invaluable to healthcare.

Protective Enclosures and Chassis from Sheet Metal Fabrication

Electronic components are sensitive and require robust protection from physical impact, moisture, and electromagnetic interference (EMI). Custom sheet metal fabrication is the go-to solution for creating durable enclosures, chassis, and project boxes for everything from consumer electronics to large industrial power supply units. Materials like aluminum, carbon steel, and stainless steel provide sturdy and rugged housing that shields the delicate electronics inside.

These enclosures can be customized with specific features like vents for cooling, cutouts for ports and switches, and mounting hardware for internal components like PCBs. The inherent properties of metal provide a degree of EMI shielding, which is crucial for ensuring the proper function of electronic devices. Whether it's a small handheld case or a large rack-mounted server chassis, custom fabrication delivers protective solutions tailored to the exact needs of the application.

Sheet Metal Fabrication for Renewable Energy and Construction

As the world shifts towards a more sustainable future, custom sheet metal fabrication is playing a crucial role in both the renewable energy sector and modern construction, providing the components needed to build a greener and more resilient infrastructure.

Sustainable Solutions with Custom Sheet Metal Fabrication in Green Tech

The renewable energy industry, including solar, wind, and energy storage, relies on high-quality metal components to ensure the long-term performance and reliability of its systems. Sheet Metal Fabrication is used to create the foundational parts that make green technology possible. This includes photovoltaic (PV) panel mounting structures, inverter and junction box enclosures, and durable cabinets for battery storage systems.

In wind energy, sheet metal is utilized in the construction of turbine nacelles, which protect critical components from the elements, as well as in the blades themselves for added strength. These parts must withstand harsh environmental conditions for decades, so materials are chosen for their corrosion resistance and durability. The fabrication process supports sustainability not only by creating the infrastructure for green energy but also through its own eco-friendly practices, such as using recycled metals and energy-efficient machinery.

Architectural and Structural Elements from Sheet Metal Fabrication

In construction, sheet metal is valued for its strength, durability, and design flexibility. It is used for both structural and architectural (aesthetic) purposes. Structural steel fabrication involves creating essential metal components for buildings that require reliable support, such as beams and frames. Architectural fabrication, on the other hand, focuses more on the visual aspect, producing elements that are both functional and aesthetically pleasing.

This can include everything from custom building facades, decorative railings, and functional staircases to weather-resistant roofing and stormwater components like gutters and downspouts. Because sheet metal is malleable, it can be formed into unique and complex shapes, allowing architects to realize their creative visions. Furthermore, many metals used in construction, like steel and aluminum, are highly recyclable, which aligns with modern green building standards and contributes to a more sustainable construction industry.

Choosing the Right Partner for Custom Sheet Metal Fabrication

Selecting the right fabrication partner is as crucial as the design of the component itself. The quality of the final product, adherence to timelines, and overall project success hinge on the capabilities, expertise, and reliability of the fabricator. A true partner does more than just manufacture parts; they provide valuable insights, ensure quality at every step, and work collaboratively to achieve the best possible outcome.

Experience and Expertise in Sheet Metal Fabrication

One of the most critical factors to consider when selecting a fabricator is their experience, especially within your specific industry. A partner with a proven track record in your field will understand the unique standards, challenges, and material requirements of your projects. They can offer valuable design-for-manufacturability (DFM) guidance, potentially suggesting modifications that enhance quality, improve functionality, and lower costs.

When evaluating a potential partner, inquire about their previous work on projects similar to yours. A strong portfolio and positive customer testimonials are good indicators of their capabilities and reliability. Furthermore, consider the experience of their workforce. A team of skilled, long-standing employees often points to a stable company that values expertise and delivers consistent, high-quality work. An experienced fabricator is not just a supplier but an extension of your own team, contributing their specialized knowledge to ensure your project's success.

Quality Assurance and Certifications in Sheet Metal Fabrication

Quality should never be compromised. A reputable fabrication shop will have a robust quality assurance system integrated into every stage of the production process, from design review to final inspection. Look for fabricators who hold internationally recognized certifications, as this demonstrates a commitment to meeting stringent quality standards.

Key certifications to look for include:

- ISO 9001:2015: This is the international standard for a quality management system (QMS). An ISO 9001 certification indicates that the fabricator has well-defined processes for ensuring consistent quality, customer satisfaction, and continuous improvement.

- American Welding Society (AWS) Certifications: For projects involving welding, having AWS-certified welders is a must. This certification proves that the welders have demonstrated a high level of proficiency and that the company adheres to industry-best practices for welding.

- Other Industry-Specific Certifications: Depending on your field, there may be other relevant certifications such as those from the American Institute of Steel Construction (AISC) for structural steel or specific standards for the aerospace and medical industries.

A certified partner provides the assurance that your components will be manufactured to the highest standards, ensuring their reliability and performance.

Comprehensive Capabilities and Material Sourcing for Sheet Metal Fabrication Projects

A fabrication partner with comprehensive in-house capabilities can significantly streamline your project. Shops that offer a full suite of services—from cutting and bending to welding, finishing, and assembly—can manage the entire production process under one roof. This minimizes the risks and logistical complexities of outsourcing different stages to multiple vendors, which can lead to delays and quality control issues. The use of state-of-the-art equipment, such as modern CNC machines and robotic systems, is also a strong indicator of a fabricator's commitment to precision and efficiency.

Equally important is their approach to material sourcing and supply chain management. The global supply chain has faced significant disruptions in recent years, making a resilient and transparent sourcing strategy essential. A reliable partner will have strong relationships with trusted material suppliers, be proactive in identifying potential sourcing challenges, and communicate transparently about any issues that could impact your project. Their ability to secure high-quality raw materials in a timely manner is fundamental to keeping your project on schedule and on budget.

Conclusion

As I’ve explored, custom sheet metal fabrication is more than just a manufacturing process; it’s a craft that combines artistry with engineering, allowing for endless possibilities in industrial design and application. The ability to create highly precise, durable, and customized components makes it a transformative force across a multitude of sectors, from automotive and aerospace to medical and renewable energy. Its impact is felt in the enhanced performance of vehicles, the reliability of life-saving medical devices, and the advancement of sustainable technologies.

The journey through the intricate world of sheet metal fabrication reveals its profound impact on industries worldwide. Its precision, adaptability, and cost-effectiveness highlight its crucial role in driving innovation and meeting the evolving demands of modern manufacturing. This essential process, powered by continuous technological advancements like AI and automation, will undoubtedly continue to shape our industrial landscape for years to come. With every perfectly formed component, we are building a more efficient, resilient, and innovative future.

For businesses looking to leverage the transformative power of custom sheet metal fabrication, partnering with a forward-thinking provider is key to success. I believe a company like SOMI Custom Parts, dedicated to efficiently and precisely integrating sheet metal fabrication resources, offers tailored solutions for clients globally, ensuring that every project achieves its full potential. The right partnership unlocks not just superior components, but a competitive edge in a rapidly changing world. I encourage you to share your thoughts on this vital industry and join the conversation on how we can continue to innovate together.