Understanding Liquid Silicone Injection Molding Technology

- Share

- Issue Time

- Feb 5,2026

Summary

Explore liquid silicone injection molding: process, advantages, material properties, applications in medical & automotive, and key challenges.

As manufacturing processes continue to evolve, understanding the nuances of various production techniques becomes crucial. Today, we're diving into the world of liquid silicone injection molding, a highly efficient and precise method for creating durable and intricate parts. This process is renowned for its ability to produce pliable, high-quality components in large volumes.

Liquid silicone rubber (LSR) has unique properties that make it an ideal material for a wide range of applications, from medical devices to automotive components and consumer products. Its remarkable flexibility, durability, and resistance to extreme temperatures set it apart from other materials. This blog post will explore the technology behind liquid silicone injection molding, its advantages, limitations, and how it compares to other molding techniques.

Join me as we uncover the fascinating process of liquid silicone injection molding and discover why it's becoming a go-to solution for high-volume, high-precision manufacturing.

What Exactly is Liquid Silicone Injection Molding?

Liquid silicone injection molding (LIM) is a manufacturing process used to create durable, pliable parts in high volumes. It involves injecting liquid silicone rubber, a two-part platinum-cured elastomer, into a mold cavity where it is heated and cured, or vulcanized, to form a solid part. This technique is particularly valued for producing parts with complex geometries, high precision, and a smooth finish, all with faster production cycles and reduced labor costs compared to traditional methods.

Exploring the Core Material: Liquid Silicone Rubber (LSR)

The heart of this technology is Liquid Silicone Rubber (LSR), a high-performance material known for its exceptional physical properties. Unlike solid silicone, LSR is supplied in a liquid form, which makes it perfect for the injection molding process, especially for parts that require intricate designs and high precision.

A Thermoset Elastomer with Unique Characteristics

Chemically, silicone rubber is a thermoset elastomer, meaning it hardens irrevocably when heated. This is due to the cross-linking of polymers that occurs during the curing process, creating strong, permanent chemical bonds. The backbone of silicone rubber consists of alternating silicon and oxygen atoms, which provides a stable structure. This composition makes LSR a synthetic resin that, once cured, locks in its physical properties like tensile strength and heat distortion temperature. This thermosetting nature is the opposite of thermoplastics, which soften when heated and can be re-melted.

Key Properties Driving Liquid Silicone Injection Molding

LSR boasts a combination of properties that make it a standout choice for demanding applications:

- Wide Temperature Range: LSR parts maintain their mechanical properties and flexibility across a vast temperature spectrum, typically from as low as -60°C up to +250°C (-76°F to +482°F).

- Biocompatibility and Purity: Inherently biocompatible and hypoallergenic, LSR does not support bacterial growth, making it a preferred material for medical devices, implants, and products with skin contact.

- Chemical Resistance and Durability: LSR is inert and does not react with most chemicals. It is also resistant to damage from water, oxidation, UV rays, and ozone, ensuring long-term stability.

- Electrical Insulation: As a dielectric material, LSR is an excellent electrical insulator, making it a safe choice for electronic components and connectors.

- Low Viscosity and Design Freedom: LSR's low viscosity allows it to flow easily into complex and thin-walled sections of a mold under lower pressure, enabling the production of intricate parts with exceptional detail.

- Optical Clarity: Many grades of LSR offer excellent transparency, which is beneficial for applications requiring visual monitoring or for creating products with a clean aesthetic.

The Automated Process of Liquid Silicone Injection Molding

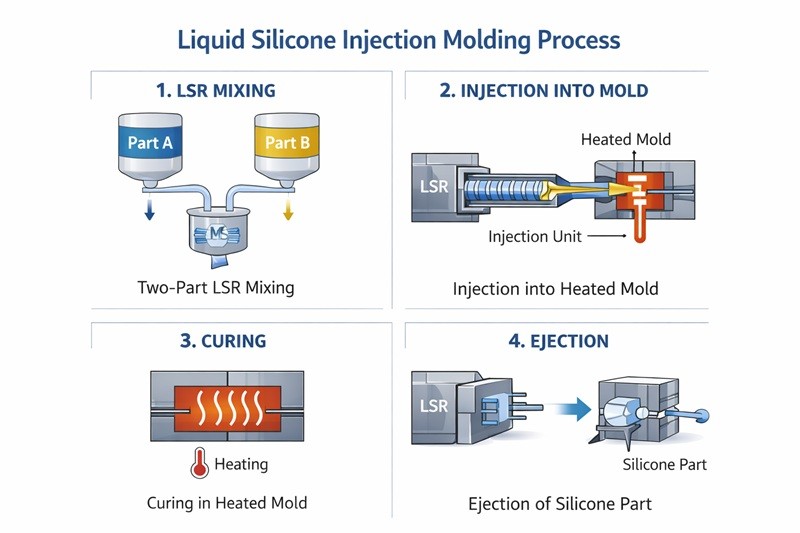

The liquid silicone injection molding process is a highly automated and efficient system designed for precision and high-volume output. It turns the two-part liquid material into a solid, durable product through a series of carefully controlled steps.

From Material Preparation to Curing

The journey from liquid to solid part follows a precise sequence:

- Material Preparation: The process begins with two separate components of liquid silicone rubber—typically a base-forming silicone (Part A) and a platinum catalyst (Part B). These components are often supplied in barrels or pails. Color pigments can also be added at this stage.

- Mixing: A metering unit pumps the two liquid materials from their supply drums at a consistent 1:1 ratio. They are then fed into a static or dynamic mixer, which thoroughly homogenizes the components just before they enter the mold. This mixing is intensive but must occur while keeping the material at a low temperature to prevent premature curing.

- Injection: The mixed LSR is injected into a heated mold. Unlike thermoplastic injection molding where the mold is cooled, the LSR mold is heated (typically between 150-200°C or 302-392°F) to initiate the curing process. The low viscosity of LSR allows it to fill the mold cavity with relatively low injection pressure.

- Curing (Vulcanization): Inside the hot mold, the LSR undergoes a chemical reaction that cross-links the polymer chains, transforming the liquid into a solid, elastic rubber part. This vulcanization process is rapid, often taking only seconds to a few minutes.

- Demolding and Post-Curing: Once the part is fully cured, the mold clamp opens, and the finished component is ejected. In many cases, a post-curing step may follow, where the molded parts are heated in an oven to accelerate vulcanization, maximize physical properties, and remove any residual volatiles.

The Role of Specialized Equipment in Liquid Silicone Injection Molding

Achieving the precision and efficiency of LSR molding requires specialized machinery. While designs can vary, the core components of a liquid silicone injection molding machine are consistent:

| Machine Component | Function |

|---|---|

| Supply Drums | These are the primary containers holding the two liquid silicone components (Part A and Part B). |

| Metering Units | This unit accurately pumps the two LSR components at a precise 1:1 ratio to ensure proper curing. |

| Mixer | A static or dynamic mixer combines the A and B components just before injection. |

| Injection Unit | This includes the barrel, screw, and nozzle responsible for pressurizing and injecting the mixed LSR into the mold. |

| Nozzle | Often equipped with an automatic shut-off valve, the nozzle deposits the material into the mold and prevents leaks. |

| Mold Clamp | This unit securely holds the mold together during the high-pressure injection and curing phases and opens it for part ejection. |

| Heated Mold | The mold itself is heated, often using electrical heaters or circulating hot water, to trigger and control the vulcanization of the LSR. |

This integrated system ensures a highly controlled, automated, and efficient production cycle.

The Compelling Advantages of Liquid Silicone Injection Molding

Liquid silicone injection molding (LIM) stands out in the manufacturing world for a multitude of reasons. It combines process efficiency, material excellence, and cost-effectiveness, making it a superior choice for a wide range of demanding applications across various industries.

Efficiency and Precision in Liquid Silicone Injection Molding

One of the most significant benefits of the LIM process is its ability to produce parts with remarkable speed and consistency, making it ideal for high-volume production where quality cannot be compromised.

Rapid Production Cycles and High Volume Output

The liquid silicone injection molding process is highly automated and boasts very fast curing times, often measured in seconds rather than minutes. This rapid vulcanization allows for significantly shorter cycle times compared to other methods like compression molding. As a result, manufacturers can achieve high production throughput, making LIM perfectly suited for projects that require a large number of identical parts quickly and efficiently. The entire process, from injecting the material to ejecting the finished part, can be fully automated, which allows a single operator to manage multiple machines, further boosting productivity.

Exceptional Accuracy and Part Consistency

Precision is a hallmark of liquid silicone injection molding. The low viscosity of LSR allows it to flow easily and fill even the most intricate and complex mold cavities, enabling the creation of parts with thin walls and fine details. This results in exceptional part-to-part consistency and the ability to maintain tight tolerances, typically ranging from +/- 0.005 inches to +/- 0.025 inches, depending on the part's complexity. The process yields parts with minimal flash (excess material), which significantly reduces or eliminates the need for secondary trimming operations. The high level of automation and the repeatable nature of the process ensure that every part produced is of the same high quality.

Material Excellence in Liquid Silicone Injection Molding

Liquid Silicone Rubber (LSR) itself is a superior material with a host of inherent properties that make it invaluable for critical applications where performance and safety are paramount.

Biocompatibility and Chemical Resistance

LSR is renowned for its outstanding biocompatibility. It is non-toxic, hypoallergenic, and does not support the growth of bacteria, making it an excellent choice for medical devices, healthcare products, and any application involving skin contact. LSR is also chemically inert, meaning it shows excellent resistance to a wide range of chemicals, including many acids and bases, as well as water and oxidation. This resilience ensures the durability and reliability of LSR parts even when exposed to harsh sterilization processes or aggressive environments.

Durability Across Extreme Temperatures

One of LSR's most notable features is its remarkable thermal stability. It can withstand a vast range of temperatures, maintaining its flexibility and mechanical properties in conditions from as low as -100°C (-148°F) to over 250°C (482°F). Unlike many other elastomers that become brittle in extreme cold or degrade in high heat, silicone rubber remains stable and functional. This exceptional durability makes it the ideal material for components used in demanding automotive under-the-hood applications, as well as in aerospace and industrial equipment exposed to extreme temperature fluctuations.

Electrical Insulation Properties

LSR is an exceptional electrical insulator. It has very high electrical resistivity and superior dielectric strength, properties that are not significantly affected by changes in temperature or immersion in water. This makes LSR an ideal material for high-voltage applications and electronic components. It is widely used to encapsulate and protect sensitive circuits, as well as for manufacturing connectors, cable sheaths, and other insulating parts, ensuring the safety and reliability of electrical systems.

Environmental and Cost Benefits of Liquid Silicone Injection Molding

Beyond its performance and precision, LIM also offers compelling advantages in terms of sustainability and long-term cost-effectiveness.

Reduced Waste and Energy Consumption

The liquid silicone injection molding process is inherently efficient, leading to minimal material waste. Advanced techniques like cold runner systems cool the material before it enters the mold, allowing for nearly zero material loss in the feed lines and eliminating trimming operations. This precision reduces scrap compared to other molding methods. Furthermore, the material itself is derived from silica (sand), an abundant natural resource. While not traditionally recyclable, silicone is highly durable, which extends product lifespans and reduces the need for frequent replacements. Some sources also note that silicone can break down naturally over time, unlike plastics that persist in the environment.

Cost-Effectiveness for High-Volume Production

While the initial investment in tooling and specialized machinery for liquid silicone injection molding can be higher than for other processes, it becomes highly cost-effective for medium to high-volume production runs. The fast cycle times, high level of automation, and reduced labor requirements significantly lower the per-part cost over the course of a long production run. The minimal material waste and low defect rates further contribute to its economic efficiency, making LIM a financially sound choice for manufacturing thousands of high-quality parts.

Navigating the Challenges of Liquid Silicone Injection Molding

While liquid silicone injection molding (LIM) offers a host of powerful advantages, it is not without its challenges. Understanding and preparing for these potential hurdles is crucial for any manufacturer considering this technology. The main drawbacks revolve around high initial costs, material complexities, and the potential for specific molding defects.

Initial Investments and Production Considerations for Liquid Silicone Injection Molding

The startup phase of a liquid silicone injection molding project requires significant financial and technical consideration. The high precision and specialized nature of the process come with notable upfront expenses.

Higher Upfront Costs for Tooling and Equipment

One of the primary challenges of LIM is the high initial investment required for tooling and machinery.

- Tooling Costs: Molds for LIM must be engineered to exceptionally tight tolerances to manage the low viscosity of liquid silicone rubber and prevent defects like flash. This requires high-grade steel and complex features such as cold runner systems. The cost for a simple, single-cavity mold can range from $5,000 to $10,000, while complex, multi-cavity molds for medical or automotive parts can easily exceed $50,000 to $100,000.

- Equipment Costs: Liquid silicone injection molding requires specialized machines equipped with precise dosing pumps, mixers, and advanced control systems. These industrial machines represent a significant capital investment, often costing anywhere from $50,000 to over $200,000.

These substantial upfront costs mean that LIM is generally more suited for high-volume production where the initial investment can be amortized over a large number of parts.

Material Costs and Processing Complexity

The material itself and the process of handling it also present challenges.

- Higher Material Price: Liquid silicone rubber is typically more expensive per kilogram than many common thermoplastic elastomers (TPEs). In 2025, general-purpose LSR could cost between $10 and $20 per kilogram, while higher-purity medical-grade LSR can range from $25 to $40 per kilogram. This higher raw material cost directly impacts the final price of each part.

- Processing Complexity: The LIM process is intricate and requires precise control over numerous variables, including temperature, pressure, and curing time. Any deviation can lead to defects. Furthermore, the platinum catalyst used in many LSR formulations can be inhibited by contact with certain compounds like sulfur, tin, or amines, which can be present in the environment or on other equipment. This requires scrupulous cleanliness and sometimes even dedicated processing rooms to prevent cross-contamination and ensure proper curing.

Addressing Potential Issues in Liquid Silicone Injection Molding

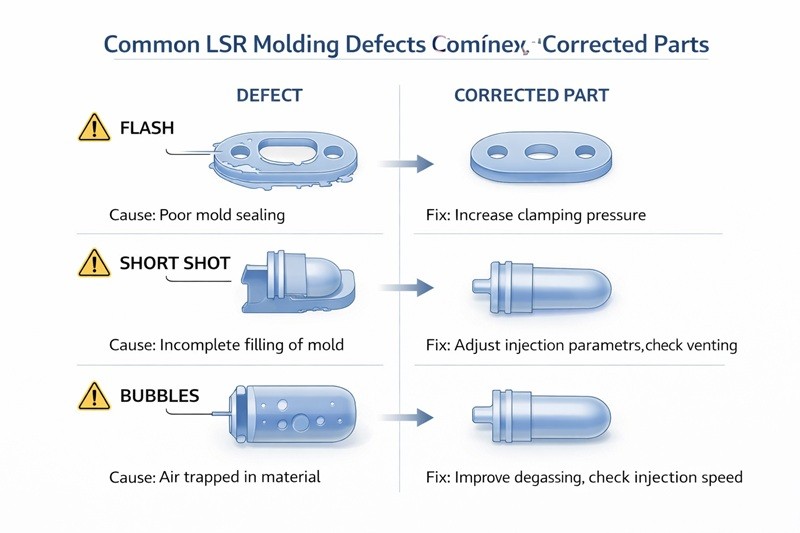

Even with precise control, various defects can arise during the molding process. Being able to identify and troubleshoot these issues is key to maintaining part quality and production efficiency.

Common Defects and Troubleshooting in Liquid Silicone Injection Molding

Several common issues can occur if process parameters are not perfectly controlled:

| Defect | Description & Common Causes | Troubleshooting Solutions |

|---|---|---|

| Flash | A thin layer of excess material appears on the part, usually at the mold's parting line. This is often caused by a mold that doesn't seal perfectly, excessive injection pressure, or low clamping force. | Increase clamping force, clean and repair mold parting lines, reduce injection pressure, and optimize venting. |

| Incomplete Fill (Short Shot) | The mold cavity is not completely filled, resulting in an incomplete part. This can be caused by insufficient material volume, low injection pressure, or the material curing too early. | Increase injection pressure or shot volume, raise mold and material temperature to improve flow, and check for clogged gates or runners. |

| Bubbles or Voids | Air gets trapped within the molded part, creating bubbles or empty spaces. This is often due to poor venting in the mold or air being introduced during the mixing process. | Improve mold venting, check for air leaks in the material supply lines, and optimize the injection speed to allow air to escape. |

| Scorching or Burn Marks | Discoloration or burn marks on the part, typically caused by trapped air that becomes super-heated under compression or silicone that cures too early during injection. | Decrease injection speed and material temperature, reduce back pressure, and ensure proper mold venting. |

| Improper Curing | The part feels sticky or does not achieve the expected hardness. This can result from incorrect mold temperature, insufficient cure time, or catalyst inhibition from contaminants. | Increase mold temperature and cure time, verify the A:B material ratio, and ensure all equipment is clean and free of inhibiting substances. |

Limitations in Hardness and Wear Resistance for Liquid Silicone Injection Molding

While LSR is an incredibly versatile material, it has certain inherent physical limitations.

- Hardness Range: While LSR is available in a wide range of durometers (hardness levels), from very soft and gel-like (below 10 Shore A) to quite firm (up to 80 Shore A), its properties can be compromised at the extremes. At very low hardness levels (below 15 Shore A), tensile strength and tear resistance tend to decrease. Conversely, very high hardness grades can become brittle and lose some of their elasticity. For example, optical-grade LSR can have a Shore A hardness of 70 and exhibit almost no elasticity.

- Wear and Tear Resistance: A notable disadvantage of silicone rubber is its relatively poor tear strength and abrasion resistance compared to many other elastomers. While this can be improved with specific formulations and additives, standard grades of LSR are not ideal for dynamic applications involving high friction or repeated scraping, as they can tear or wear down more easily than materials designed for such purposes.

By understanding these initial costs, processing intricacies, and material limitations, manufacturers can better prepare for a successful liquid silicone injection molding project and an empowered decision-making.

Liquid Silicone Injection Molding in Action: Key Applications

The unique properties of Liquid Silicone Rubber (LSR), combined with the precision of the injection molding process, make it an invaluable material across a wide array of industries. From life-saving medical devices to rugged automotive parts and sophisticated consumer electronics, LSR provides solutions where durability, safety, and performance are critical.

Life Sciences and Medical Devices through Liquid Silicone Injection Molding

The medical industry relies heavily on LSR due to its outstanding biocompatibility, purity, and ability to be sterilized. Because it is well-tolerated by the human body and does not cause adverse reactions, it is a preferred material for devices that come into contact with tissue and fluids. The process is ideal for manufacturing critical components for surgical devices, wearables, and more where quality is imperative.

Seals, Gaskets, and Implants with Liquid Silicone Injection Molding

LSR's flexibility, durability, and inert nature make it perfect for producing critical medical components:

- Seals and Gaskets: LSR is used to create high-precision, leak-proof seals and gaskets for medical equipment, infusion pumps, and respiratory masks, ensuring airtight and watertight performance.

- Implants: Given its biocompatibility and ability to mimic soft tissue, LSR is a choice material for long-term implantable devices such as cochlear implants, soft tissue fillers, and components for artificial heart valves. Its durability ensures long-term patient safety.

- Catheters and Tubing: The flexibility and chemical resistance of LSR make it ideal for manufacturing medical tubing, catheters, and components for drug delivery systems.

- Surgical Instruments: LSR is overmolded onto surgical tool handles to provide better grip, comfort, and control for surgeons, with the added benefit that the components can be repeatedly sterilized.

Automotive and Industrial Components Utilizing Liquid Silicone Injection Molding

In the automotive and industrial sectors, components must withstand harsh conditions, including extreme temperatures, chemical exposure, and constant vibration. LSR's exceptional stability and durability make it a perfect fit for these demanding environments.

Engine Seals and Electrical Connectors with Liquid Silicone Injection Molding

LSR helps improve the reliability and longevity of vehicles and machinery in several key areas:

- Seals and Gaskets: Automotive applications include engine gaskets, O-rings, and other seals that must endure high temperatures and exposure to oils and coolants without degrading.

- Electrical Connector Seals: LSR is used to manufacture weatherproof seals for electrical connectors, protecting sensitive wiring harnesses and electronic components from moisture, dust, and dirt. Its excellent electrical insulation properties are critical for the safety and performance of modern vehicles, especially electric vehicles (EVs).

- Hoses and Bellows: Components that regulate the flow of air, fuel, or fluids benefit from LSR's flexibility and resistance to chemicals and extreme temperatures, preventing cracks and leaks over time.

- Vibration Dampeners: Thanks to its elasticity, LSR is molded into engine mounts and other components to absorb vibration and reduce noise, leading to a smoother and quieter operation.

Consumer Electronics and Everyday Products by Liquid Silicone Injection Molding

The demand for durable, functional, and aesthetically pleasing consumer products has driven the adoption of LSR in everyday items. From kitchenware to the latest tech gadgets, LSR provides protection, functionality, and a premium feel.

Waterproof Seals and Soft-Touch Components from Liquid Silicone Injection Molding

LSR adds significant value to consumer electronics and other goods:

- Waterproof Seals: Many of today's electronic devices, such as smartphones, smartwatches, and drones, rely on precision-molded LSR gaskets and seals to achieve water and dust resistance. These tiny, complex seals protect delicate internal electronics from environmental damage.

- Soft-Touch Surfaces: LSR is used to create soft, durable, and skin-friendly surfaces for a variety of products, including remote controls, kitchen utensils, and wearable device bands. Its pleasant tactile feel enhances the user experience, and its resistance to sweat and oils ensures it remains clean and durable over time.

- Keypads and Buttons: The elasticity and durability of LSR make it ideal for creating responsive and long-lasting keypads and buttons for a wide range of electronic devices and appliances.

- Baby Products: Because it is biocompatible, odorless, and tasteless, LSR is widely used to make baby bottle nipples, pacifiers, and teethers, ensuring the highest level of safety for infants.

Comparing Liquid Silicone Injection Molding to Other Methods

Choosing the right manufacturing process is a strategic decision that directly impacts product quality, cost, and performance. While liquid silicone injection molding (LIM) is a powerful technique, it's essential to understand how it stacks up against other common methods, particularly those involving thermoplastic elastomers (TPEs). This comparison helps clarify when LIM is the optimal choice.

Liquid Silicone Injection Molding versus Thermoplastic Elastomers (TPE)

At a glance, Liquid Silicone Rubber (LSR) and Thermoplastic Elastomers (TPE) appear similar—both are flexible, rubber-like materials used in injection molding. However, they are fundamentally different in their chemical structure and processing, which leads to distinct performance characteristics.

Material Behavior and Processing Differences in Liquid Silicone Injection Molding vs. TPE

The most critical distinction is between their classifications: LSR is a thermoset, while TPE is a thermoplastic. This dictates how they behave when heated.

- Processing of LSR (Thermoset): LSR starts as a two-part liquid that is mixed and then injected into a heated mold. The heat triggers an irreversible chemical reaction (curing or vulcanization) that permanently cross-links the polymer chains. Once cured, an LSR part cannot be re-melted. This thermosetting process gives LSR its superior stability at high temperatures.

- Processing of TPE (Thermoplastic): TPE is supplied as solid pellets that are melted in the injection barrel to become a viscous liquid. This liquid is then injected into a cooled mold, where it solidifies. This process is reversible; a TPE part can be melted down and reprocessed multiple times, which is a major advantage for recycling.

This fundamental difference leads to distinct molding process characteristics:

| Feature | Liquid Silicone Injection Molding (LSR) | Thermoplastic Elastomer (TPE) Injection Molding |

|---|---|---|

| Material Type | Thermoset (cures with heat, irreversible) | Thermoplastic (melts with heat, reversible) |

| Process | Two-part liquid is mixed and injected into a hot mold to cure. | Solid pellets are melted and injected into a cool mold to solidify. |

| Cycle Time | Generally slower due to the time required for chemical curing within the mold. | Typically faster because it relies on cooling, which can be quicker than curing. |

| Recyclability | Not typically recyclable due to its thermoset nature. | Highly recyclable, as scrap material can be re-melted and reused. |

| Design Freedom | Greater design freedom due to its very low viscosity, allowing for thin walls and complex geometries. Undercuts are easier to de-mold because of high flexibility. | Viscosity is higher, which can limit flow into very fine details. Part design must carefully consider features like wall thickness and draft angles. |

Performance and Cost Considerations for Liquid Silicone Injection Molding and TPE

The differences in processing and material structure translate directly to performance and cost.

Performance:

- Temperature Resistance: LSR vastly outperforms TPE in both high and low-temperature environments. It remains stable and flexible at temperatures where TPE would soften, melt, or become brittle.

- Compression Set: LSR has an excellent compression set, meaning it returns to its original shape after being compressed for a long period. This makes it superior for high-performance seals and gaskets.

- Biocompatibility: Medical-grade LSR is inherently pure and biocompatible, making it the standard for medical implants and skin-contact devices. While some TPEs are medical-grade, LSR is often preferred for more critical applications.

- Chemical Resistance: LSR offers excellent resistance to a broad range of chemicals, UV, and ozone. TPE's resistance is generally more moderate.

Cost:

- Material Cost: TPE is generally more cost-effective on a per-kilogram basis than LSR. General-purpose LSR is often higher priced, and the cost increases significantly for specialty and medical grades.

- Tooling and Equipment Cost: TPE can be processed on standard injection molding machines, leading to lower tooling and equipment costs. LSR requires specialized, more expensive equipment and high-precision molds to prevent flash.

- Production Cost: For high-volume runs, TPE is often faster and cheaper due to faster cycle times and recyclability of scrap material. However, for applications where the superior performance of LSR is essential, the higher initial cost is often justified by the product's durability and reliability.

When to Choose Liquid Silicone Injection Molding Over Other Techniques

The decision to use liquid silicone injection molding should be driven by the specific requirements of the application. While processes like compression molding or thermoplastic injection molding have their place, LIM becomes the clear choice under certain conditions.

Optimizing for Precision, Volume, and Specific Material Properties with Liquid Silicone Injection Molding

Liquid silicone injection molding is the ideal choice when your project demands one or more of the following:

- Exceptional Precision and Complex Geometries: When parts require intricate details, very thin walls, or complex shapes, the low viscosity and excellent flow properties of LSR are unmatched. The process allows for the consistent production of highly detailed components with minimal defects.

- High Performance in Extreme Environments: If the part must function reliably under extreme heat or cold, or if it will be exposed to harsh chemicals or UV radiation, LSR's inherent stability makes it the superior material choice. This is critical for automotive, aerospace, and outdoor applications.

- Mandatory Biocompatibility and Sterilizability: For any medical device that involves patient contact, especially implants, respiratory equipment, or surgical tools, medical-grade LSR is the industry standard. Its ability to withstand repeated sterilization cycles (autoclave, gamma, EtO) without degradation is a crucial advantage.

- Reliable Sealing and Long-Term Durability: For applications requiring a durable, long-lasting seal that will not deform under sustained pressure, such as in high-performance gaskets and O-rings, LSR's excellent compression set is indispensable.

- High-Volume, High-Quality Production: Although the setup costs are high, the automation, fast curing, and consistency of the LIM process make it a cost-effective solution for manufacturing thousands or millions of identical, high-quality parts.

Ultimately, choosing liquid silicone injection molding is an investment in quality, durability, and precision, especially for products where failure is not an option.

In conclusion, liquid silicone injection molding stands out as a highly effective and versatile manufacturing process, offering significant advantages in producing precise, durable, and high-quality parts across numerous industries. Its ability to create complex geometries with exceptional consistency and speed makes it a formidable choice for modern manufacturing needs.

While initial costs for tooling and materials, along with the complexity of the process, require careful consideration, the long-term benefits often make it the superior choice. The enhanced product performance, from outstanding temperature and chemical resistance to biocompatibility, provides a level of reliability that other materials cannot match. Furthermore, the efficiency of high-volume automated production and the potential for reduced waste contribute to its overall value, particularly in demanding applications.

As we've seen, understanding the intricacies of liquid silicone injection molding is key to leveraging its full potential. By weighing its unique advantages against its specific challenges, product designers and engineers can drive innovation, improve product quality, and ultimately achieve a competitive edge in the marketplace. We hope this exploration has provided valuable insights into this fascinating technology. What are your thoughts on its applications? Share this article and join the conversation to further explore the future of manufacturing.