Understanding 3D Printing Technologies: A Manufacturer's Perspective

- Share

- Issue Time

- Jan 9,2026

Summary

This article, written from the perspective of a 3D Printing Parts manufacturer, provides a comprehensive guide to additive manufacturing, detailing various 3D printing technologies, their applications, and criteria for selecting the most suitable one.

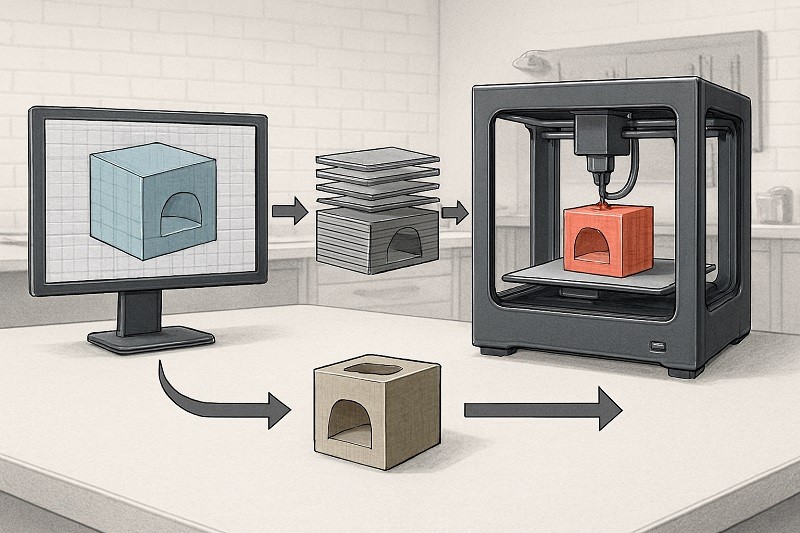

As a 3D Printing Parts manufacturer, we've witnessed firsthand the transformative power of additive manufacturing. This guide will help you understand the core technologies and applications of 3D printing from our perspective. The landscape of manufacturing is constantly evolving, with 3D printing at the forefront of innovation. We'll explore various 3D printing technologies, their benefits, and how selecting the right one can optimize your production, whether for prototyping or end-use parts.

Exploring Key 3D Printing Technologies from a 3D Printing Parts Manufacturer

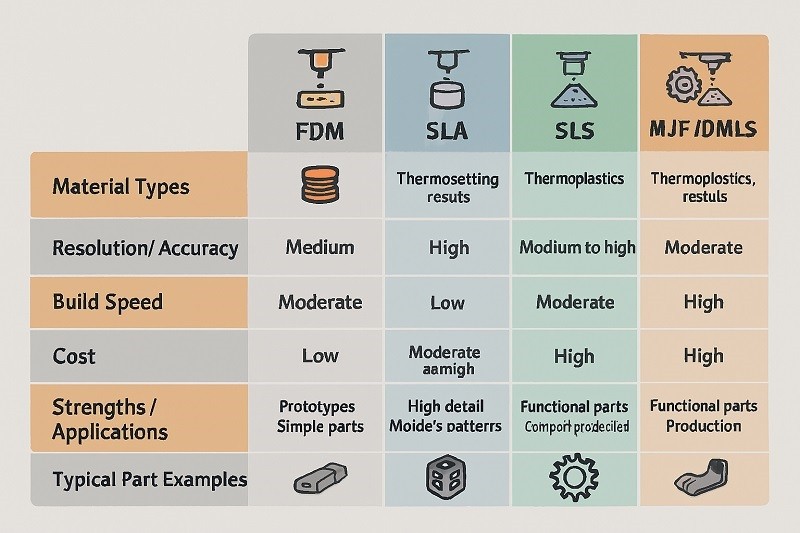

Understanding the different types of 3D printing is the first step toward leveraging its full potential. Each technology offers a unique combination of speed, cost, material compatibility, and part properties. As experienced manufacturers, we've honed our expertise in several key processes to meet a wide range of industrial demands. Below, we break down the technologies we use most frequently and explain why they might be the right fit for your project.

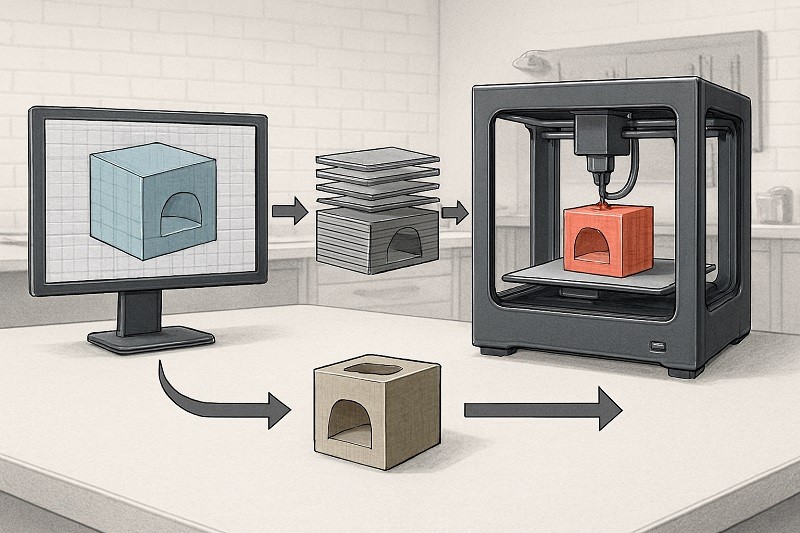

Fused Deposition Modeling (FDM): The Accessible Choice

Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), is one of the most widespread and recognized 3D printing technologies. Its popularity stems from its straightforward process and cost-effectiveness, making it a go-to for rapid prototyping and even some end-use applications. The technology was first patented in 1989 by Scott Crump, who founded Stratasys and pioneered the method by experimenting with a glue gun to melt and layer plastic.

The FDM process works by extruding a thermoplastic filament through a heated nozzle, melting the material and depositing it layer by layer onto a build platform according to a digital CAD file. Each layer cools and fuses with the one below it, gradually forming a solid object. While consumer-grade FDM printers are very affordable, professional and industrial systems offer higher precision, larger build volumes, and compatibility with a broader range of engineering-grade materials.

Key characteristics and applications:

- Material Variety: FDM supports a wide array of thermoplastic materials. Common options include the biodegradable and easy-to-print PLA, ideal for concept models, and the more durable and heat-resistant ABS, which is suited for functional parts. Other a materials include PETG, which offers a balance of strength and chemical resistance, and high-performance polymers like Nylon, known for its toughness and wear resistance. Exotic filaments are also available, which are infused with materials like carbon fiber, wood, or metal powder.

- Cost-Effectiveness: FDM is generally the most affordable 3D printing technology, especially for producing prototypes and simple parts, making it excellent for rapid design iteration.

- Limitations: Parts produced via FDM can be anisotropic, meaning they possess different strength values depending on their orientation, which can be a limitation for certain high-stress industrial uses. The process can also result in visible layer lines, which may require post-processing like sanding or polishing to achieve a smooth surface.

From a manufacturer's standpoint, FDM is invaluable for creating proof-of-concept models, jigs, fixtures, and low-volume functional parts where speed and low cost are paramount.

Multi Jet Fusion (MJF): Speed and Consistency for a 3D Printing Parts Manufacturer

Developed and introduced by HP in 2016, Multi Jet Fusion (MJF) has quickly become an indispensable technology for producing highly accurate and durable parts at scale. It belongs to the powder bed fusion family of technologies and is renowned for its speed, consistency, and ability to produce functional parts with excellent mechanical properties. In fact, each MJF printer itself contains over 140 parts printed using MJF, a testament to the technology's reliability for end-use components.

The MJF process begins with a thin layer of polymer powder, typically Nylon, spread across the build platform. An inkjet array moves across this powder, selectively depositing two liquid agents: a fusing agent, which absorbs infrared energy, and a detailing agent, which is applied around the edges to refine part resolution and surface quality. An infrared heating unit then passes over the bed, melting and fusing the areas where the fusing agent was applied. This cycle repeats layer by layer. A key benefit is that the surrounding unfused powder supports the part during printing, eliminating the need for separate support structures and allowing for complex geometries.

Key characteristics and applications:

- Speed and Scalability: MJF is significantly faster than many other 3D printing methods, especially for full build chambers, making it highly cost-efficient for small to medium production runs.

- Isotropic Properties: MJF parts exhibit consistent mechanical properties in all directions (isotropic), which is a major advantage over FDM. This makes them suitable for demanding functional applications.

- Material and Color: The most common material is Nylon 12 (PA12) due to its balanced mechanical profile and good chemical resistance. HP has also introduced materials like the more ductile PA11 and a flexible TPU. A unique feature of some MJF systems is the ability to print functional, engineering-grade parts in full color, which is a significant breakthrough.

- Surface Finish: Parts typically have a slightly grainy, light gray finish but can be post-processed (e.g., dyed black or vapor smoothed) to achieve different colors and smooth, sealed surfaces.

As manufacturers, we rely on MJF for producing end-use parts, complex prototypes, and series production where part quality, speed, and cost-per-part are critical. It successfully bridges the gap between prototyping and large-scale manufacturing.

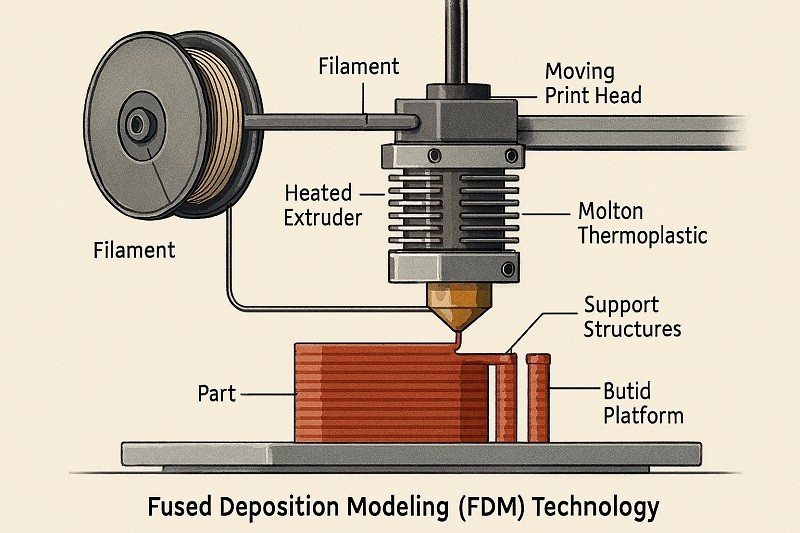

Selective Laser Sintering (SLS): Robust and Versatile

Selective Laser Sintering (SLS) is another powder bed fusion technology that has been a trusted choice for engineers and manufacturers for decades. Patented in the 1980s by Carl Deckard at the University of Texas, its original purpose was to accelerate prototyping. Today, it's used for everything from rapid prototyping to low-volume manufacturing of strong, functional parts.

The SLS process is similar to MJF in that it uses a powder bed, but differs in its energy source. Instead of inkjet agents and infrared light, SLS uses a high-power laser to selectively sinter (fuse) polymer powder particles together based on a 3D model. A blade or roller spreads a thin layer of powder, the laser scans a cross-section of the part, and the platform lowers for the next layer. Like MJF, the surrounding unsintered powder acts as a natural support, making SLS ideal for creating parts with complex internal features and undercuts.

Key characteristics and applications:

- Proven Materials: The most common material for SLS is Nylon (such as PA12 and PA11), a capable engineering thermoplastic that creates strong, stiff, and durable parts. These nylons can also be reinforced with additives like glass fibers (PA12-GF) or carbon fibers (PA12-CF) to enhance stiffness and temperature resistance. Other materials include flexible TPU and Polypropylene (PP).

- Mechanical Performance: SLS parts possess nearly 100% density and mechanical properties comparable to those made with traditional injection molding, making them a viable substitute for many applications. They are impact-resistant and suitable for functional components like snap-fits and living hinges.

- Design Freedom: The self-supporting nature of the powder bed allows for the creation of intricate and complex geometries that would be impossible with other methods. This also enables "nesting," where multiple parts can be packed tightly together in the build volume, maximizing productivity.

- Industry Applications: SLS is widely used in the automotive and aerospace industries for prototyping and producing components like brackets and enclosures. It is also used in the medical field for creating custom prosthetics and surgical guides, and by companies like Porsche to produce on-demand spare parts for classic cars.

For manufacturers, SLS is a workhorse technology for producing tough, functional prototypes and end-use parts that require proven material properties and geometric complexity.

Metal 3D Printing Processes: Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM)

Metal 3D printing represents a significant leap forward, enabling the direct production of complex, high-strength metal parts that are often impossible to make with traditional methods. The two leading powder bed fusion technologies for metals are Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM).

Direct Metal Laser Sintering (DMLS)

DMLS, sometimes used interchangeably with Selective Laser Melting (SLM), uses a high-power fiber laser to selectively fuse fine metal powder particles. DMLS doesn't fully melt the powder but heats it to the point of atomic fusion, a process known as sintering. SLM, on the other hand, fully melts the powder. The process occurs in a chamber filled with inert gas to prevent oxidation. The resulting parts are accurate, dense, and possess mechanical properties that can rival or even exceed those of traditionally manufactured parts.

- Materials: DMLS works with a wide range of metals and metal alloys, including stainless steel, aluminum, titanium, nickel alloys, and copper.

- Advantages: Its key advantage is the ability to produce highly complex geometries, such as internal channels for conformal cooling in tooling or lightweight lattice structures for aerospace components. This capability reduces part counts, assembly time, and weight. DMLS parts typically have a better surface finish and higher resolution compared to EBM.

- Applications: DMLS is used extensively in aerospace, medical, automotive, and motorsports industries for everything from patient-specific implants and surgical tools to high-performance engine components.

Electron Beam Melting (EBM)

EBM, developed by Arcam AB (now part of GE Additive), uses a high-energy electron beam instead of a laser to melt metal powder layer by layer. The entire process takes place in a vacuum at high temperatures (up to 1,000 °C), which helps to relieve internal stresses and produce parts with superior material properties, free from impurities.

- Materials: The material selection for EBM is more limited than for DMLS and must be conductive. It is best suited for high-temperature and reactive materials like titanium alloys, cobalt-chrome, and nickel-based superalloys.

- Advantages: Due to the more powerful energy source and the ability to use multiple beams at once, EBM can be significantly faster than DMLS. The high-temperature process results in parts with low residual stress and excellent density.

- Applications: EBM is ideal for producing parts for the aerospace (e.g., turbine blades), medical (e.g., orthopedic implants), and defense industries where material integrity is paramount. Studies have shown EBM-produced titanium implants demonstrate excellent osseointegration.

As a manufacturer, choosing between DMLS and EBM depends on the application's specific requirements, including material choice, desired feature resolution, and production speed. Both technologies unlock unparalleled possibilities for creating optimized, high-performance metal components.

Choosing the Right 3D Printing Technology as a 3D Printing Parts Manufacturer

Selecting the optimal 3D printing technology is a critical decision that influences a project's cost, timeline, and the final part's performance. As a manufacturer, our process isn't about picking a single "best" technology, but about conducting a thorough analysis to align the right process with the specific demands of the part. This decision hinges on a careful balance of material properties, cost constraints, and design complexity.

Matching Performance Requirements with Materials

The first step is always to define the part's intended application and performance needs. This dictates the required material properties, which in turn narrows down the technology choices. A part's requirements can range from simple aesthetic representation to rigorous mechanical function under stress.

Key Material Properties to Consider:

- Tensile Strength: This measures a material's resistance to breaking under tension and is critical for load-bearing or structural components. When a part needs high strength, materials like carbon-fiber-reinforced Nylon (FDM) or certain SLA resins are excellent choices.

- Flexibility and Elongation: For parts that need to bend or stretch without breaking, such as gaskets or living hinges, materials are evaluated on their flexural modulus and elongation at break. A low flexural modulus indicates flexibility. TPU, available for both SLS and FDM, is a prime choice for such applications.

- Heat Resistance: If a part will be exposed to high temperatures, such as an automotive component near an engine, its Heat Deflection Temperature (HDT) is a crucial metric. High-performance polymers like PEEK and ULTEM (FDM) or specific resins like Rigid 10K (SLA) are designed for these environments.

- Impact Strength: For parts that must withstand sudden loads or drops, like electronics enclosures or protective casings, impact resistance is key. Materials like ABS, PETG, and Nylon excel in this area.

- Chemical and UV Resistance: For parts used outdoors or in industrial settings, resistance to chemicals and UV radiation is vital to prevent degradation. ASA filament is an excellent choice for outdoor applications due to its superior UV resistance, while materials like PETG and PP offer good chemical resistance.

The following table provides a general comparison to help guide material selection based on common requirements:

| Requirement | Recommended Material(s) | Suitable Technologies | Common Applications |

|---|---|---|---|

| High Strength | Nylon, Carbon-Fiber Nylon, Polycarbonate (PC), Metal | SLS, FDM, DMLS/EBM | Functional parts, jigs, fixtures, end-use components |

| Flexibility | TPU, Flexible Resins | SLS, FDM, SLA | Gaskets, seals, wearables, shock absorbers |

| High Detail | Standard & Engineering Resins | SLA | Visual prototypes, medical models, fine jewelry |

| Heat Resistance | PEEK, ULTEM, High-Temp Resins, Metals | FDM, SLA, DMLS/EBM | Under-hood auto parts, aerospace components |

| Biocompatibility | Biocompatible Resins, Titanium, PA11 | SLA, DMLS, EBM, SLS | Medical implants, surgical guides, orthotics |

By translating performance needs into specific material properties found on a technical data sheet, we can confidently select a material and its corresponding technology to ensure the final part functions as intended.

Cost and Lead Time Considerations

For any manufacturing project, budget and timeline are primary constraints. 3D printing offers a different cost structure than traditional methods, largely driven by material costs, machine runtime, and labor, rather than expensive tooling. Understanding these factors is key to optimizing a project for both cost and speed.

Factors Influencing Cost:

- Material Cost: This is often the most significant cost driver. Commodity plastics like PLA are the least expensive, while high-performance polymers and metals are at the upper end of the price spectrum.

- Model Volume and Geometry: Larger parts require more material and longer print times, directly increasing the cost. While 3D printing handles complexity well, extremely intricate features can increase print time and post-processing effort, which also adds to the cost.

- Printing Technology: The machine itself carries a cost. The depreciation, maintenance, and operational expenses of an industrial printer (which can range from $140,000 to over $380,000) are factored into the part price. FDM is generally the most economical for larger parts, while technologies like SLA and MJF offer different cost-benefit ratios based on detail and speed.

- Labor: Skilled labor is essential for machine setup, part removal, post-processing (like support removal, sanding, or dyeing), and quality control.

Factors Influencing Lead Time:

- Print Time: The sheer time a part takes to print is a major component of lead time. This is affected by part size, complexity, and the chosen technology.

- Batching and Quantity: For powder bed technologies like SLS and MJF, lead time can be optimized by "nesting" or stacking many parts into a single build. This makes these technologies highly efficient for producing hundreds of parts at once, often lowering the cost-per-part as well.

- Post-Processing: The time required for finishing steps after printing can significantly impact the overall lead time. A part requiring extensive support removal, sanding, painting, and assembly will take longer than a part that can be used directly off the printer. One of the main benefits of AM is that it often requires no tooling, which can reduce lead times from weeks or months to just days.

As manufacturers, we provide instant quotes that analyze a design's geometry to balance these factors. For example, a large, simple part might be most cost-effective with FDM, while an order for 200 small, complex housings would likely be faster and cheaper with MJF due to its batching efficiency.

Navigating Design Complexity and Geometric Freedom

One of the most revolutionary aspects of 3D printing is the near-total design freedom it offers. Additive manufacturing builds parts layer by layer, freeing designers from the constraints of traditional methods like CNC machining or injection molding. This freedom allows for the creation of shapes and features that were previously impossible to produce, a concept central to Design for Additive Manufacturing (DfAM).

Harnessing Geometric Freedom:

- Complex Geometries: DfAM encourages the use of intricate shapes, internal channels, and organic forms without adding to the manufacturing cost. For example, a CNC machine is limited by its tool's ability to physically reach every surface, making undercuts and complex internal cavities impossible. 3D printing has no such limitation.

- Part Consolidation: Multiple components of an assembly can be redesigned and printed as a single, complex part. This reduces assembly time, eliminates potential points of failure (like joints or fasteners), and often results in a lighter, stronger final product.

- Lightweighting with Lattices:

- In industries like aerospace and automotive, reducing weight is critical. AM allows for the integration of internal lattice structures, which maintain mechanical strength while drastically reducing material usage and part weight—in some cases by up to 70%. These structures are impossible to create with traditional subtractive methods.

- Mass Customization: Because AM does not require tooling, producing slight variations of a design costs roughly the same as making many identical parts. This opens the door for mass customization, enabling patient-specific medical implants, custom-fit consumer products, and other personalized solutions.

However, DfAM is not just about complexity; it's about designing intelligently for the chosen process. This includes considering factors like build orientation to optimize strength, minimizing the need for support structures, and adhering to the minimum feature size and wall thickness of a given technology. By embracing DfAM principles, we can move beyond simply replicating existing designs and instead create parts that are truly optimized for performance, weight, and function, fully unlocking the transformative potential of additive manufacturing.

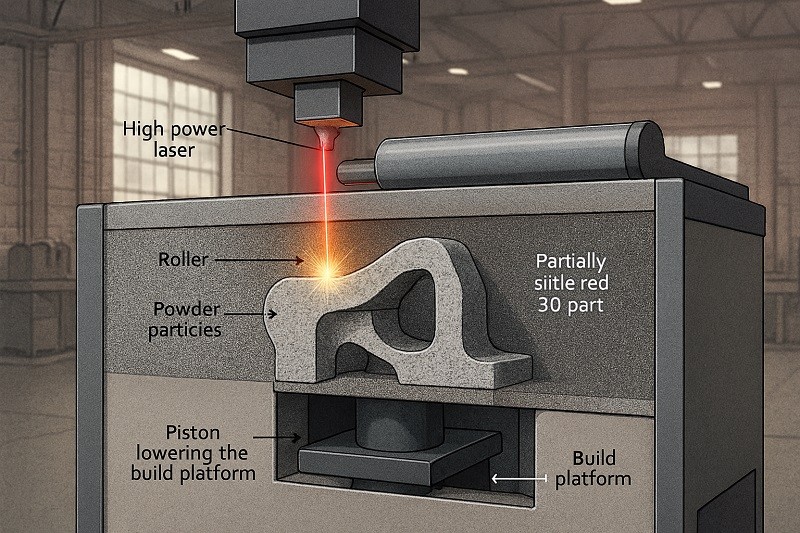

3D Printing vs. Injection Molding: A 3D Printing Parts Manufacturer's Perspective

The choice between 3D printing and injection molding is a classic manufacturing dilemma. While both produce plastic parts, they operate on fundamentally different principles. 3D printing, or additive manufacturing, builds parts layer by layer from a digital file. Injection molding is a more traditional process that involves injecting molten material into a metal mold. As a manufacturer offering both prototyping and production services, we don't see them as competing technologies but as complementary tools. Often, a product's lifecycle benefits from using both: 3D printing for agile prototyping and injection molding for cost-effective mass production.

Material Options and Properties

The choice and performance of materials are critical, and this is one area where the two processes have distinct differences.

Injection Molding Materials: Injection molding boasts an enormous range of material options, including thousands of thermoplastics, thermosets, and elastomers. This extensive library allows for precise tuning of a part's mechanical, thermal, and chemical properties. Common materials include:

- ABS, Polycarbonate (PC), Polypropylene (PP), and Polyethylene (PE).

- Engineering-grade plastics with additives like glass or carbon fibers to enhance strength and stiffness.

- Highly flexible elastomers and silicone rubbers.

The key advantage here is that parts are formed from a single, uniform layer of molten plastic, resulting in isotropic parts with consistent, predictable, and robust mechanical properties. Injection molded parts are generally stronger and denser than their 3D printed counterparts.

3D Printing Materials: While the list of 3D printing materials is growing rapidly, it is currently more limited than injection molding. The most common materials are thermoplastics like PLA, ABS, PETG, and Nylon, as well as photopolymer resins for SLA. Even when the same polymer type is used (e.g., ABS), the end-use properties will differ from an injection molded equivalent. This is because 3D printed parts are built layer-by-layer, which can create microscopic voids and directional weaknesses (anisotropy), especially in FDM parts. Technologies like SLS and MJF produce parts with much better isotropic properties, but injection molded parts generally remain the standard for ultimate strength and durability.

Cost and Scalability for Production Volumes

Cost and scalability are where the two processes diverge most dramatically. The decision often comes down to the required production volume and the project's budget structure.

3D Printing:

- Cost Structure: The primary advantage of 3D printing is the absence of tooling costs. The cost is driven by the amount of material used, the machine run time, and post-processing labor. This results in a relatively flat, linear cost-per-part, regardless of volume.

- Scalability: 3D printing is exceptionally cost-effective for low-volume production, from a single prototype up to several hundred parts. It is ideal for rapid prototyping, as designs can be tweaked and reprinted in hours without financial penalty. However, because each part is made individually and cycle times can be long (from minutes to hours per part), the cost-per-part does not decrease significantly with volume, making it less economical for mass production.

Injection Molding:

- Cost Structure: Injection molding is defined by a high upfront investment in tooling—the creation of a steel or aluminum mold can cost anywhere from a few thousand to tens of thousands of dollars and take weeks or months to fabricate. However, once the mold is made, the per-part cost is extremely low, often just pennies for materials and machine time.

- Scalability: This process is built for mass production. With cycle times measured in seconds, injection molding can churn out thousands or even millions of identical parts at an unbeatable per-unit cost. It is the undisputed choice for high-volume manufacturing where consistency is key.

The Break-Even Point: The "break-even point" is the production volume at which injection molding becomes more cost-effective than 3D printing. This point is not fixed and depends on part complexity and size, but it typically falls somewhere between 500 and 2,000 units. For volumes below this threshold, 3D printing is generally cheaper and faster. Above it, the high initial tooling cost of injection molding is amortized over the large number of parts, making it the more economical choice. For example, one analysis found the break-even point for a specific part to be 13,050 units, demonstrating the significant cost advantage of 3D printing for low and medium volumes.

Achieving Desired Surface Finish and Accuracy

The final appearance and precision of a part are critical for many applications, and here, injection molding traditionally holds an advantage, though advancements in 3D printing are closing the gap.

Injection Molding:

- Surface Finish: Injection molded parts typically have a very smooth surface finish directly out of the mold. The quality of the finish is directly related to the mold's internal surfaces; a highly polished mold can produce parts with a glossy, consumer-ready appearance.

- Accuracy: This process is known for its high repeatability and ability to hold very tight tolerances, making it ideal for parts that need to fit together precisely.

3D Printing:

- Surface Finish: The surface of a 3D printed part is technology-dependent. FDM parts are known for their visible layer lines, which can require significant post-processing like sanding or polishing to smooth out. SLS and MJF parts have a matte, slightly grainy texture. SLA produces the smoothest surfaces of any 3D printing technology, often approaching the quality of injection molding.

- Accuracy: While industrial 3D printers can achieve high accuracy, they generally have wider tolerances than injection molding. The layer-by-layer nature of the process can introduce slight variations.

- Post-Processing: Achieving a smooth, finished surface on 3D printed parts often requires post-processing. This can include support removal (for FDM and SLA), sanding, vapor smoothing (for technologies like MJF), painting, or coating. These extra steps add time and labor cost to the production process. Injection molded parts, in contrast, often need little more than trimming the sprue.

As manufacturers, we guide our clients through this decision by focusing on their end goal. If a project requires thousands of identical, high-strength parts with a flawless finish, injection molding is the clear path. If the need is for rapid, low-volume production of complex or customized parts, 3D printing is the superior, more agile solution.

Leveraging 3D Printing Services: What We Look For in a 3D Printing Parts Manufacturer

While owning 3D printing equipment in-house has its advantages, partnering with a specialized 3D printing service bureau offers access to a wider range of technologies, materials, and deep expertise without the significant capital investment. As manufacturers ourselves, we know what separates a simple parts provider from a true strategic partner. When we evaluate a potential partner, we look for excellence in three key areas: support and expertise, quality and reliability, and their role in our broader supply chain strategy.

The Value of Excellent Customer Support and Expertise

The complexity of additive manufacturing means that challenges can arise at any stage, from material selection to design optimization. This is where a partner's expertise becomes invaluable. A great 3D printing service isn't just a machine operator; they are a team of engineers and technicians who provide critical guidance.

Key aspects we value include:

- Design for Additive Manufacturing (DfAM) Guidance: An expert partner can analyze a part design and suggest modifications that will improve printability, reduce costs, and enhance performance. This collaborative approach leverages their deep knowledge of different technologies' nuances.

- Material Science Knowledge: A skilled team should be able to make informed material recommendations based on the part's application, going beyond just the common options. They should understand the trade-offs between strength, flexibility, temperature resistance, and cost for a vast library of materials.

- Proactive Problem-Solving: Exceptional customer service involves more than just fixing problems when they occur. It's about anticipating potential issues—like warping, weak points, or difficult-to-remove supports—and addressing them before the print even starts. This proactive support saves time, reduces waste, and ensures the final part meets expectations. Studies show that 71% of B2B customers in the 3D printing space value high-quality support over pricing.

Ultimately, a manufacturer's technical expertise and commitment to customer support transform them from a simple vendor into an extension of our own engineering team.

Ensuring Quality, Reliability, and Certifications

For industrial and end-use parts, quality and reliability are non-negotiable. A 3D printed part, no matter how complex, is only useful if it performs as intended consistently. When vetting a manufacturing partner, we scrutinize their commitment to quality management and their ability to produce reliable, production-grade components.

Key indicators of quality and reliability include:

- Robust Quality Management Systems (QMS): A serious manufacturing partner will have a documented QMS that governs every step of their process, from incoming material inspection to final part verification. This ensures traceability, repeatability, and accountability.

- ISO and Industry-Specific Certifications: Certifications are a formal validation of a manufacturer's commitment to quality.

- ISO 9001:2015: This is the baseline international standard for quality management. It demonstrates that a provider has controlled and continuously improving processes to meet customer requirements.

- AS9100D: Building on ISO 9001, this standard includes additional stringent requirements for the aerospace and defense industries. An AS9100-certified manufacturer is qualified to produce high-reliability components for critical applications.

- ISO 13485: This certification is crucial for manufacturing medical devices, ensuring the provider meets the strict regulatory requirements for products like implants and surgical tools.

- Process Control and Machine Maintenance: Industrial printers require regular calibration and preventative maintenance to ensure consistent performance. A quality-focused provider will have strict protocols for machine upkeep and will trace any part failures to monitor and maximize the performance of each machine.

- Part Inspection: A thorough quality control process includes multiple inspection points. This can involve visual checks, measuring critical dimensions to confirm they meet required tolerances, and inspecting surface finish quality.

While consumer-grade 3D printing has made the technology more accessible, industrial applications demand a level of rigor that only a professional, certified manufacturer can provide. The reliability of a 3D-printed part depends heavily on the material, design, and, most importantly, the quality of the process used to create it.

Strategic Partnerships and Supply Chain Optimization

In today's volatile global landscape, a resilient and agile supply chain is a major competitive advantage. 3D printing is a transformative technology in this regard, and a good manufacturing partner plays a key role in supply chain optimization.

How 3D Printing Services Enhance the Supply Chain:

- Reduced Lead Times and On-Demand Production: Traditional manufacturing often involves long lead times for tooling and overseas shipping. 3D printing enables on-demand, localized production that can deliver parts in days instead of weeks or months. This is particularly valuable for producing spare parts or managing just-in-time (JIT) inventory.

- Digital Inventory: Instead of warehousing physical parts that may become obsolete, companies can maintain a "digital inventory" of part files. When a part is needed, it can be printed on-demand by a manufacturing partner, reducing storage costs and waste.

- Part Consolidation and Simplification: As discussed under DfAM, 3D printing allows multiple components to be consolidated into a single, complex part. This simplifies the supply chain by reducing the number of sourced components, suppliers to manage, and assembly steps required.

- Supply Chain Resilience: By partnering with local or regional 3D printing services, companies can mitigate risks associated with global supply chain disruptions, such as trade conflicts or shipping bottlenecks. It creates a more flexible and responsive manufacturing base.

A true strategic partner in additive manufacturing helps companies leverage these benefits. They move beyond being a simple parts provider to become an integral node in a modern, digital supply chain, enabling greater efficiency, innovation, and resilience. The collaboration between a company and its AM service provider can accelerate the adoption of the technology, turning manufacturing challenges into competitive advantages.

Specialized Applications and Future Trends for a 3D Printing Parts Manufacturer

Additive manufacturing is not just an alternative to traditional production; it's a catalyst for innovation across a multitude of sectors. The unique capabilities of 3D printing—unparalleled design freedom, on-demand production, and material efficiency—are enabling breakthroughs that were once considered impossible. As we look to the future, several applications and trends stand out, signaling where the industry is headed.

The Role of 3D Printing in Advancing Industries

For the past decade, 3D printing has evolved from a prototyping tool into a strategic, production-grade solution. This transformation is reshaping product development and manufacturing across key industries.

- Aerospace and Defense: This sector was one of the earliest adopters of AM, recognizing its potential to create lightweight, high-strength components. Every gram saved on an aircraft translates to significant fuel savings and improved efficiency. 3D printing is used to produce complex engine parts, fuel nozzles, lightweight structural brackets, and drone components. The ability to consolidate multipart assemblies into a single printed component reduces weight, shortens the supply chain, and minimizes potential points of failure.

- Automotive: The automotive industry leverages 3D printing to accelerate product development cycles and for lightweighting. Companies like Porsche have used 3D printed aluminum pistons to increase engine horsepower while reducing weight. Beyond prototypes, manufacturers are now printing custom jigs, fixtures, and even end-use parts. The technology is critical for producing complex components with internal channels for cooling or optimized airflow, leading to better vehicle performance and fuel efficiency.

- Medical and Healthcare: 3D printing has revolutionized personalized medicine. It enables the creation of patient-specific implants (such as hip and cranial plates), prosthetics, and surgical guides based on a patient's own CT or MRI scans. This level of customization improves patient outcomes, reduces surgery times, and speeds up recovery. Innovations in bioprinting are also paving the way for fabricating tissues and, eventually, transplantable human organs.

Aluminum Alloy 3D Printing: Lightweighting and High Strength

One of the most exciting trends in metal additive manufacturing is the growing use of aluminum alloys. Aluminum is prized for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity, making it an ideal material for high-performance applications.

When combined with 3D printing, the advantages of aluminum are magnified. Laser Powder Bed Fusion (LPBF) is the most common method used, melting fine aluminum powder layer by layer to create dense, robust parts.

Key benefits and applications include:

- Superior Strength-to-Weight Ratio: 3D printed aluminum parts can be designed with complex internal lattice structures, achieving significant weight reduction (lightweighting) without sacrificing mechanical strength. This is invaluable in aerospace for creating fuselage brackets and in the automotive sector for suspension components and engine parts. Honda, for example, achieved a 50% weight reduction in a crankshaft through generative design and 3D printing.

- High-Performance Alloys: Commonly used alloys like AlSi10Mg offer high strength and good thermal properties, making them suitable for heat exchangers and engine components. High-strength alloys like Al7075 are used for high-stress structural parts in aircraft. New aluminum alloys developed specifically for AM can exhibit strength up to five times higher than standard cast aluminum.

- Design Freedom: AM makes it possible to produce aluminum parts with integrated features like cooling channels, which is difficult or impossible with traditional casting or machining. This leads to more efficient and higher-performing components.

Sustainability in Additive Manufacturing

As industries worldwide focus on reducing their environmental impact, 3D printing is emerging as a more sustainable manufacturing alternative. While the technology is not entirely without its ecological footprint—energy consumption and material sourcing are still concerns—it offers significant advantages over traditional methods.

How 3D Printing Contributes to Sustainability:

- Material Efficiency and Waste Reduction: Additive manufacturing is inherently less wasteful than subtractive processes like CNC machining, which can generate as much as 95% scrap material. AM builds parts layer by layer, using only the material needed for the final product. This dramatically reduces material waste.

- Localized, On-Demand Production: By enabling production closer to the point of use, 3D printing reduces the immense carbon footprint associated with global shipping and logistics. On-demand manufacturing also prevents overproduction and the waste associated with large physical inventories.

- Recycling and Circular Economy: The industry is making strides in material recyclability.

- In powder bed processes like SLS, unsintered powder can be collected, refreshed, and reused in subsequent builds, with some systems allowing for up to 80% powder reuse.

- Filament recyclers are available that can shred failed FDM prints and extrude them into new spools.

- Companies are increasingly developing materials from recycled feedstocks, such as rPLA and rPETG, and bio-based polymers like PA11, which is derived from castor oil. This aligns with the principles of a circular economy, where resources are kept in use for as long as possible.

While challenges remain in making all 3D printing materials and processes fully sustainable, the technology provides a clear path toward a more resource-efficient and environmentally responsible manufacturing ecosystem.

Conclusion

As a manufacturer deeply invested in the capabilities of additive manufacturing, we understand that selecting the optimal 3D printing technology and the right partner is crucial for project success. The journey from a digital file to a functional, real-world part is filled with critical decisions. By carefully considering your design requirements, material needs, production volume, and budget, you can unlock the full, transformative potential of additive manufacturing. The continuous advancements in 3D printing technologies offer unprecedented opportunities for innovation, customization, and efficiency across every industry.

The landscape is dynamic, with new materials, faster machines, and more sustainable practices emerging constantly. We are committed to helping our clients navigate this exciting field. By leveraging the unique strengths of technologies like FDM, MJF, SLS, and DMLS, and by embracing principles of smart design and quality assurance, we can help you achieve superior results with your 3D printed parts. The future of manufacturing is not just about making things; it's about making things better, faster, and more sustainably.

We encourage you to explore these technologies further and consider how they can revolutionize your next project. Feel free to share this guide with your colleagues and start a conversation about how you can integrate the power of 3D printing into your manufacturing strategy.