Low-Volume CNC Machining: The Strategic Advantage in Modern On-Demand Manufacturing

- Share

- Issue Time

- Dec 13,2025

Summary

Low-volume CNC machining offers agility, cost efficiency, and production-grade quality for on-demand manufacturing of 10–10,000 units.

Why Low-Volume Manufacturing is More Than Just a Stepping Stone

In the landscape of modern manufacturing, the conversation has long been dominated by the scale and efficiency of mass production. The goal was simple: produce as much as possible to drive down the cost per unit. However, a strategic shift is underway. For startups, innovators, and industries requiring high degrees of customization, low-volume CNC machining is emerging not just as a preliminary step, but as a powerful and sustainable manufacturing strategy. It serves a crucial production range, typically from 10 to 10,000 units, bridging the gap between one-off prototyping and full-scale mass production. This approach prioritizes agility, reduces financial risk, and accelerates time-to-market, making it an essential tool for today's dynamic market demands.

Unpacking CNC Machining: The Core of Precision

At its heart, Computer Numerical Control (CNC) machining is a subtractive manufacturing process that uses computer-guided tools to remove material from a solid block (the workpiece) to create a final part. From metals like aluminum and stainless steel to a wide array of plastics, CNC machines can produce components with exceptionally tight tolerances and complex geometries. This precision is what makes it invaluable for creating high-quality, production-grade parts, whether you're making one or a thousand.

The Surge in On-Demand, Low-Volume Production

Market trends are increasingly favoring customization and rapid innovation cycles. Consumers want personalized products, and industries like aerospace, medical devices, and high-end automotive require specialized components in quantities that don't justify the massive upfront investment of mass production tooling. This is where low-volume manufacturing shines. It allows businesses to produce parts as needed, responding swiftly to market feedback or design updates without being burdened by large inventories of obsolete stock.

Key Advantages of a Low-Volume CNC Strategy

Opting for small-batch production offers a host of strategic benefits that are critical for competitiveness in many sectors.

- Unmatched Design Flexibility: With low-volume CNC, design modifications can be made between small batches with minimal cost implications. This iterative process is perfect for refining a product based on real-world testing and feedback before committing to a final design. Companies can experiment with different materials and geometries to optimize performance.

- Accelerated Speed to Market: Traditional mass production involves long lead times for creating molds and tooling, which can take months. Low-volume CNC machining can begin almost immediately after a CAD design is finalized. This allows businesses to launch products, test markets, and start generating revenue far more quickly.

- Significant Reduction in Upfront Costs: The primary cost barrier for mass production is tooling (molds, dies), which can run into tens or even hundreds of thousands of dollars. Low-volume CNC bypasses this entirely, making it financially accessible for startups and small businesses. This dramatically lowers the financial risk associated with launching a new product.

- Production-Grade Quality from the Start: Unlike some prototyping methods, CNC machining uses the same materials and provides the same precision as final production parts. This makes it ideal for functional testing, pre-launch certification, and even for creating end-use parts for niche applications.

- Minimized Inventory and Waste: By producing only what is needed, companies can avoid the costs and risks of overproduction and large inventory storage. This on-demand approach is not only financially prudent but also more environmentally sustainable by reducing material waste.

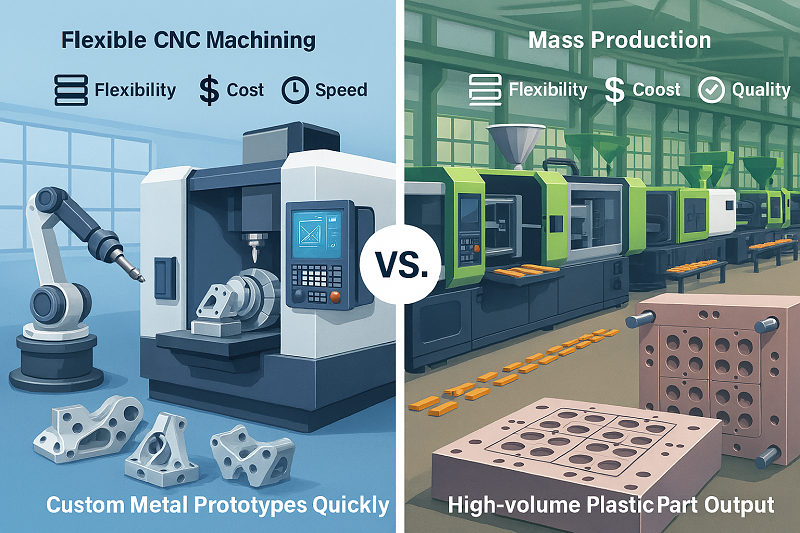

Low-Volume CNC vs. Mass Production: A Comparative Analysis

Choosing the right manufacturing path depends on a clear understanding of the trade-offs. While mass production excels at producing high volumes of a stable design cheaply, low-volume CNC offers vital flexibility.

| Feature | Low-Volume CNC Machining | Mass Production (e.g., Injection Molding) |

|---|---|---|

| Production Volume | Ideal for 10 – 10,000 units | 10,000+ units, often in the millions |

| Upfront Costs | Very low (no custom tooling) | Very high (expensive molds/dies required) |

| Cost Per Unit | Higher, but decreases with quantity | Extremely low at very high volumes |

| Lead Time | Short (days to weeks) | Long (months for tooling and setup) |

| Design Flexibility | High (easy to iterate and modify) | Very low (changes require costly tooling rework) |

| Material Variety | Very wide range of machinable metals and plastics | More limited to specific moldable materials |

Ideal Applications for Low-Volume CNC Machining

This manufacturing method is not a one-size-fits-all solution, but it is the perfect choice for several key scenarios:

High-Fidelity Prototyping and Testing

For engineers who need to validate a design with parts made from production-grade materials, CNC machining is the gold standard. It allows for rigorous functional and performance testing before any investment is made in expensive tooling.

Bridge Production

Low-volume CNC is the perfect “bridge” to mass production. It allows a company to get its product to market and begin sales while the complex and time-consuming tooling for high-volume manufacturing is being prepared. This closes the revenue gap and provides valuable early market data.

Niche Markets and Customization

For products with a limited but dedicated customer base, such as luxury goods, specialized industrial equipment, or customized automotive parts, mass production is often impractical. Low-volume production allows for profitable manufacturing of these items.

End-of-Life and Spare Part Management

When a product is nearing the end of its lifecycle, or for creating spare parts on-demand, maintaining expensive tooling is inefficient. A digital inventory of CAD files allows parts to be machined in small batches as needed, reducing storage costs and waste.

Exploring Materials: From Plastic to Titanium

The versatility of CNC machining is enhanced by the vast selection of compatible materials. This allows designers to match the material perfectly to the application's requirements.

- Metals: Aluminum (e.g., 6061, 7075), Stainless Steel (e.g., 303, 304, 316L), Titanium, Brass, Copper

- Plastics: ABS, Polycarbonate, Nylon, Delrin (POM), PEEK

This wide range ensures that parts can be created with the desired mechanical properties, weight, and chemical resistance.

Understanding the Cost Dynamics

While the per-unit cost in low-volume CNC is higher than in mass production, the total project cost is often much lower for small quantities. Pricing is typically based on machine time, material costs, and the complexity of the part. To manage costs, designers can follow Design for Manufacturability (DFM) principles, such as simplifying geometry, avoiding deep pockets, and specifying tolerances only where functionally necessary.

Selecting the Right Manufacturing Partner

Choosing the right partner is critical for a successful low-volume production run. Look for a supplier with demonstrated expertise in your desired materials and a strong track record of quality control. Clear communication, transparency in pricing, and a willingness to provide DFM feedback are hallmarks of a great partner who can help optimize your design for efficiency and cost.

The Future is Agile and On-Demand

Low-volume CNC machining is more than a manufacturing process; it's a strategic enabler of agility and innovation. It aligns perfectly with the principles of Industry 4.0, where digital designs can be turned into physical products anywhere in the world, on demand. As markets continue to fragment and product lifecycles shorten, the ability to produce high-quality parts quickly and with minimal financial risk will be a defining feature of successful enterprises. By moving beyond the prototype phase, low-volume production has solidified its role as a cornerstone of modern, strategic manufacturing.