How to Select the Right Injection Molding Manufacturers for Your Project

- Share

- publisher

- SOMI Custom Parts

- Issue Time

- Nov 9,2025

Summary

This guide helps select injection molding manufacturers: Define needs (prototyping to high-volume, commodity/engineering plastics, overmolding/insert molding); Evaluate expertise (DFM analysis, automation, certifications); Prioritize quality (FAI, ISO standards, traceability); Focus on communication, cost transparency, and reliable delivery for efficient partnerships.

Choosing the right injection molding manufacturers can significantly impact your project's success, influencing quality, production timelines, and overall costs. With thousands of injection molding companies available, both domestically and internationally, knowing how to evaluate potential partners is crucial for any product manufacturer.

The injection molding process, favored for its efficiency and versatility in creating complex geometries with high precision, is a cornerstone of modern manufacturing. Therefore, finding an injection molding manufacturer that aligns with your specific needs will ensure your product moves from concept to reality smoothly and cost-effectively.

This guide is designed to help you navigate the essential factors for selecting an injection molding manufacturer, ensuring you find a partner that not only meets your specifications but also contributes to your long-term success.

Defining Your Project Needs for Injection Molding Manufacturers

Before you can select the right partner, you must have a crystal-clear understanding of your project's specific requirements. A detailed project definition is the foundation for effective communication and accurate quoting. It allows potential manufacturers to assess if their capabilities align with your needs and prevents costly misunderstandings down the line. This initial step involves a deep dive into your expected production volume, material specifications, and any specialized processes your part may require.

Understanding Production Volume and Capacity

Production volume is one of the most critical factors in selecting a manufacturer. A partner specializing in low-volume prototyping is often not the best fit for a project requiring millions of parts per year, and vice versa. Understanding your own needs—from initial prototypes to full-scale production—is essential for finding a manufacturer with the right capacity and cost structure.

Matching Volume to Injection Molding Manufacturers

Your production needs will dictate the type of tooling and the scale of the manufacturer you should seek. It's important to align your project's volume with a manufacturer's specialty to optimize cost and efficiency.

- Prototyping & Low-Volume Production (100 - 10,000 parts): For startups, new product introductions, or niche markets, low-volume production is ideal. It often involves simpler, less expensive aluminum molds. Manufacturers in this space are geared for quick turnarounds and frequent design changes. Look for partners who explicitly offer rapid prototyping and low-volume manufacturing services.

- Mid-Volume Production (10,000 - 100,000 parts): This stage requires more durable tooling, often made from P20 steel, to balance mold longevity with cost. A manufacturer handling this volume should have a good mix of automated and manual processes and a robust project management system to handle sustained production runs.

- High-Volume Production (100,000+ parts): For mass-market products, high-volume production is necessary. This requires hardened steel molds with multiple cavities, designed to last for millions of cycles. Top-tier manufacturers in this category feature extensive automation, scientific molding practices, and 24/7 operations to maximize output and maintain consistency. High-volume partners are a significant investment and require stringent vetting.

Assessing Equipment and Tonnage Capabilities

The physical size and complexity of your part determine the required size of the injection molding machine, which is measured in tonnage. Tonnage refers to the clamping force needed to keep the two halves of the mold closed during the injection process. Using a machine with the wrong tonnage can lead to defects like flash (if the force is too low) or damage to the mold (if it's too high).

When evaluating a manufacturer, you must inquire about their range of press sizes. A reputable partner should readily provide an equipment list. This information confirms their ability to produce your specific part and indicates the scope of projects they can handle.

| Part Characteristic | Required Tonnage Range (Approx.) | Common Applications |

|---|---|---|

| Small, simple parts (e.g., bottle caps, gears) | 20 - 100 tons | Consumer electronics, small mechanical components |

| Medium-sized parts (e.g., electronic enclosures, hand tools) | 100 - 500 tons | Medical devices, automotive interiors, appliance housings |

| Large parts (e.g., automotive bumpers, large containers, pallets) | 500 - 4,000+ tons | Automotive body panels, industrial bins, outdoor furniture |

A manufacturer with a wide range of press tonnages is often more versatile and can serve as a long-term partner as your product line expands.

Identifying Material and Application Requirements

The choice of plastic resin is fundamental to your product's performance, durability, appearance, and cost. Each material has a unique set of properties, and selecting the right one depends entirely on the part's end use. A knowledgeable injection molding partner can provide invaluable guidance, but you should have a baseline understanding of your material needs.

Selecting the Right Plastic Resins

There are thousands of plastic resins available, broadly categorized as commodity plastics and engineering plastics. Your choice will depend on factors like mechanical strength, temperature resistance, chemical resistance, flexibility, and color.

- Commodity Plastics: These are inexpensive and used for everyday applications. Examples include Polypropylene (PP) for packaging, Polyethylene (PE) for bottles, and Polystyrene (PS) for disposable containers.

- Engineering Plastics: These offer superior mechanical and thermal properties for more demanding applications. Examples include Polycarbonate (PC) for its impact strength (e.g., lenses, safety goggles), Acrylonitrile Butadiene Styrene (ABS) for its rigidity and toughness (e.g., LEGO bricks, electronic housings), and Nylon (PA) for its wear resistance (e.g., gears, bearings).

Consult with your potential manufacturing partner about your application. An experienced molder will have deep expertise in various resins and can recommend materials that meet your performance requirements while optimizing for cost and manufacturability. They can also advise on additives for color, UV resistance, or flame retardancy.

Considering Specialized Injection Molding Processes

Standard injection molding is highly versatile, but some designs benefit from specialized techniques. Discussing these with potential manufacturers can reveal their technical depth and ability to handle complex projects.

- Insert Molding: This process involves placing a non-plastic component (like a metal screw thread or electrical contact) into the mold before injecting the plastic. The plastic flows around the insert, creating a single, integrated part.

- Overmolding: This technique molds a second layer of soft-touch material, typically a thermoplastic elastomer (TPE), over a rigid plastic substrate. It's widely used to add grips to handles, seal gaskets, or improve aesthetics.

- Multi-Shot Molding (2K Molding): This advanced process uses a single mold to inject multiple materials (often different colors or types) in a single machine cycle. It’s highly efficient for creating complex parts like toothbrush heads or power tool handles with integrated soft-grip features.

- Gas-Assisted Injection Molding: This technique injects nitrogen gas into the mold after the plastic, hollowing out thick sections of the part. This saves material, reduces weight, and helps eliminate sink marks.

A manufacturer’s experience with these specialized processes is a strong indicator of their technical prowess and ability to tackle innovative product designs.

Evaluating Experience and Technical Expertise of Injection Molding Manufacturers

A manufacturer's experience and technical capabilities are the bedrock of a successful partnership. An experienced team can foresee potential design flaws, optimize production processes, and troubleshoot issues before they escalate into costly delays. Their technical expertise ensures that your parts are produced with precision, consistency, and quality, leveraging the latest advancements in manufacturing technology.

The Value of Industry Experience

Theoretical knowledge is no substitute for hands-on experience. A manufacturer who has been in the business for a long time has likely encountered and solved a wide array of challenges. This institutional knowledge is invaluable, particularly for complex projects or those in highly regulated industries.

A Track Record of Success with Injection Molding Manufacturers

The best predictor of future success is past performance. When evaluating a potential partner, look for tangible proof of their expertise and reliability. Don't just take their word for it—ask for evidence.

- Case Studies: Detailed case studies demonstrate a manufacturer's problem-solving skills. They should outline the initial challenge, the solution they implemented, and the positive outcomes for the client, such as cost reduction, improved part quality, or faster time to market.

- Client Testimonials and References: Authentic testimonials provide social proof of a manufacturer's quality and customer service. Go a step further and ask for references from clients with projects similar to yours. A confident manufacturer will gladly connect you with satisfied customers.

- Portfolio Review: Ask to see examples of parts they have produced. This allows you to physically assess their quality of work, including details like surface finish, parting line consistency, and the complexity of the geometries they can handle.

Breadth of Market Specialization

While a generalist molder can be suitable for simple projects, manufacturers with specialization in specific markets offer a distinct advantage. Industry-specific experience means they are already familiar with the unique standards, regulations, and material requirements of your field.

- Medical: Medical device manufacturing requires strict adherence to FDA regulations, ISO 13485 certification, and production in controlled environments (cleanrooms). A medical specialist understands material biocompatibility, sterilization processes, and the need for rigorous documentation and traceability.

- Automotive: The automotive industry demands high-volume production with extreme precision and durability. Manufacturers in this space are typically IATF 16949 certified and have deep expertise in materials that can withstand harsh temperatures and vibrations.

- Aerospace: This sector requires parts that are both incredibly strong and lightweight. Aerospace molders have experience with high-performance polymers and must follow stringent AS9100 quality standards and provide complete part traceability.

- Consumer Electronics: This fast-paced industry requires rapid development cycles and a focus on aesthetics. Experienced molders in this space excel at achieving high-quality surface finishes, tight tolerances for snap-fits, and quick turnaround times.

Partnering with a specialist minimizes risk and ensures your product meets the necessary compliance and performance criteria.

Assessing Technical Capabilities and Advanced Technology

The right equipment and engineering support are critical for transforming your design into a high-quality physical product. A manufacturer's investment in technology is a direct reflection of their commitment to quality, efficiency, and innovation.

Modern Equipment and Automation from Injection Molding Manufacturers

Outdated equipment can lead to inefficiencies, inconsistent quality, and longer cycle times. A forward-thinking manufacturer invests in modern, well-maintained machinery and automation to stay competitive.

- Scientific Molding: Ask if the manufacturer employs scientific or "decoupled" molding principles. This data-driven approach optimizes each stage of the injection process to ensure maximum consistency and repeatability from shot to shot and run to run.

- Automation & Robotics: The use of robotics for tasks like part removal, inspection, and packaging reduces labor costs, minimizes the risk of damage, and improves cycle time consistency. 24/7 automated operations are a hallmark of high-volume, high-efficiency producers.

- Real-Time Monitoring: Advanced machines often include process monitoring systems that track key variables like temperature, pressure, and injection speed in real time. This allows operators to detect and correct deviations instantly, preventing the production of out-of-spec parts.

Engineering Support and Value-Added Services

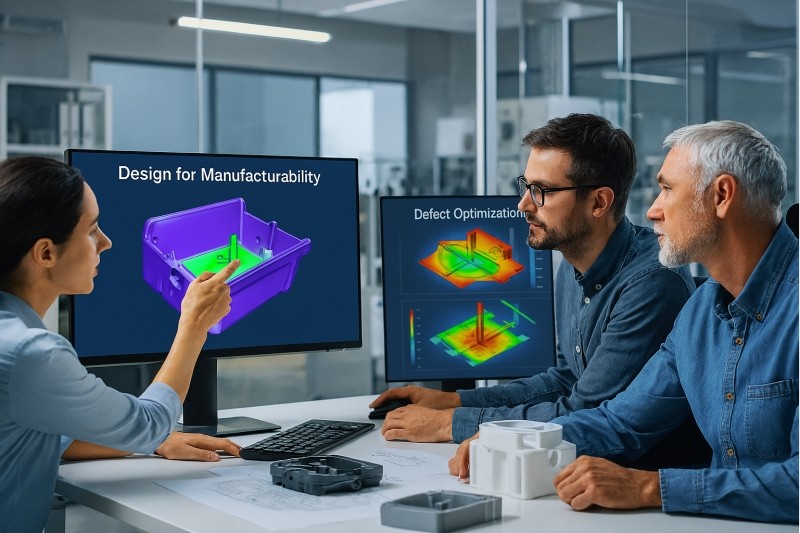

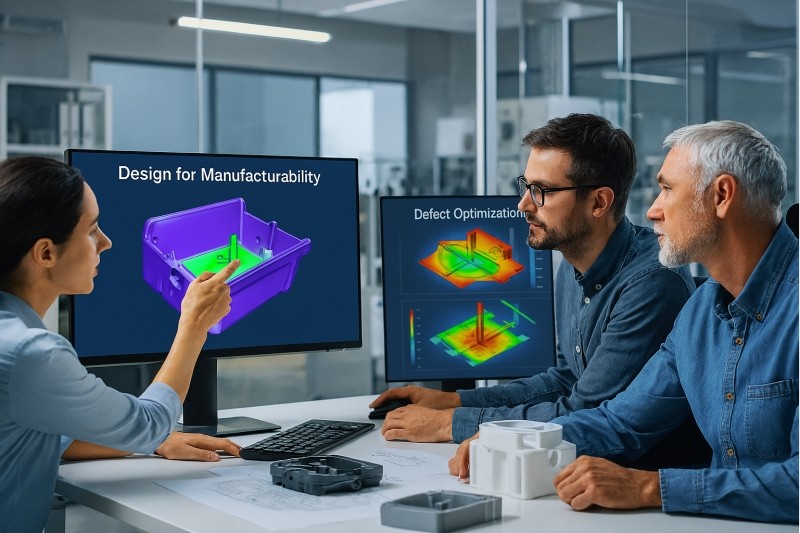

A true manufacturing partner does more than just mold parts; they act as an extension of your engineering team. Early engagement with their experts can lead to significant improvements in your product's design and manufacturability.

- Design for Manufacturability (DFM): This is one of the most valuable services a manufacturer can offer. A DFM analysis involves a thorough review of your part design to identify potential issues that could affect molding, such as improper wall thickness, sharp corners, or unfeasible undercuts. Implementing DFM feedback early can save thousands of dollars in mold rework and production delays.

- Mold Flow Analysis: This simulation software predicts how melted plastic will flow through the mold. It helps optimize gate locations, predict potential defects like weld lines or air traps, and ensure the part fills completely and uniformly.

- In-House Tooling: A manufacturer with in-house capabilities for mold design, fabrication, and maintenance has greater control over quality and lead times. If a mold needs repair or modification, it can be handled on-site quickly, minimizing production downtime.

- Secondary Operations: Look for a partner who can provide a complete solution. Value-added services like ultrasonic welding, pad printing, assembly, custom packaging, and logistics management streamline your supply chain and reduce the number of vendors you need to manage.

Prioritizing Quality Assurance and Compliance in Injection Molding Manufacturers

Quality is non-negotiable. A single batch of defective parts can lead to product failures, recalls, reputational damage, and significant financial losses. Therefore, a manufacturer's commitment to quality assurance should be a primary focus of your evaluation. This commitment is demonstrated through robust quality control systems, adherence to internationally recognized standards, and a culture of continuous improvement.

Robust Quality Control Systems of Injection Molding Manufacturers

A comprehensive quality control (QC) system is a multi-stage process that begins long before production and continues even after the parts are shipped. It's about proactively preventing defects, not just catching them at the end. When vetting a manufacturer, inquire about their specific QC procedures.

- First Article Inspection (FAI): Before any full production run begins, the manufacturer should produce a small number of parts (the "first articles") and meticulously inspect them against your 2D drawings and 3D CAD models. This FAI report confirms that the mold is producing parts that meet every specified dimension and tolerance. You should be required to approve this report before mass production commences.

- In-Process Inspection: Quality a a continuous effort. During the production run, operators and quality technicians should perform regular checks at set intervals. This may involve visual inspection for cosmetic defects and dimensional checks using tools like calipers, micrometers, or custom gauges. Real-time process monitoring also plays a key role here.

- Final Inspection and Testing: Before shipping, a final batch inspection should be conducted based on an agreed-upon sampling plan (e.g., AQL - Acceptable Quality Limit). This final check verifies that the entire order meets your quality standards. Depending on the application, this may also include functional testing, material property verification, or color matching with a spectrophotometer.

Essential Certifications and Standards for Injection Molding Manufacturers

Certifications from internationally recognized bodies are a clear indicator that a manufacturer has a mature and well-documented quality management system (QMS). They provide objective, third-party validation of a company's processes and commitment to quality. While certifications don't guarantee a perfect part every time, they show that a system is in place to manage quality and address issues systematically.

ISO 9001 and IATF 16949 for Injection Molding

These are two of the most critical certifications to look for in a manufacturing partner.

- ISO 9001:2015: This is the international standard for a Quality Management System. A company with ISO 9001 certification has demonstrated that its processes are defined, controlled, and continuously improved. It covers everything from how they handle customer requirements and design processes to how they manage suppliers and corrective actions. It is the foundational quality standard for most credible manufacturers.

- IATF 16949:2016: This is a technical specification for automotive sector Quality Management Systems. It incorporates all of ISO 9001 and adds a host of more stringent requirements specific to the automotive industry, such as advanced product quality planning (APQP) and production part approval process (PPAP). Even if your product is not automotive-related, a manufacturer with IATF 16949 certification operates at an extremely high level of process control and defect prevention, which benefits all customers.

Traceability and Defect Prevention

In the event a defect is discovered, the ability to trace its origin is crucial. A robust traceability system allows a manufacturer to quickly identify the scope of the problem and perform a root cause analysis to prevent recurrence.

- Material Lot Traceability: The manufacturer should be able to trace the specific lot of raw material used for every single part they produce. If a material defect is found, they can isolate all affected parts, a critical capability for medical and automotive products.

- Process Data Logging: Modern molding machines log process parameters for every cycle. This data is invaluable for troubleshooting. If a defect like a short shot occurs, engineers can analyze the pressure, temperature, and velocity data from that specific cycle to understand what went wrong.

- Corrective and Preventive Action (CAPA): A mature QMS includes a formal CAPA process. When a non-conformance is identified, a systematic investigation is launched to determine the root cause. A corrective action is implemented to fix the immediate problem, and a preventive action is put in place to ensure it never happens again. Ask a potential partner to walk you through their CAPA process.

The Importance of Communication, Cost, and Reliability with Injection Molding Manufacturers

Beyond technical skills and quality systems, the "soft" factors of a manufacturing partnership are just as critical to project success. Clear communication, a transparent understanding of cost, and steadfast reliability form the foundation of a healthy, long-term relationship. A breakdown in any of these areas can derail a project, even if the manufacturer has state-of-the-art equipment.

Effective Communication and Customer Service

Clear, consistent, and proactive communication is the lifeblood of any manufacturing project. Misunderstandings can lead to incorrect parts, missed deadlines, and soured relationships. Excellent customer service isn't just about being friendly; it's about providing timely, accurate information and acting as a true partner.

- Dedicated Point of Contact: You should be assigned a dedicated project manager or account manager who is your single point of contact. This person should be knowledgeable about your project and empowered to get answers from engineering, production, and quality departments.

- Proactive Updates: A great partner doesn't wait for you to ask for an update. They provide regular, scheduled progress reports on tooling fabrication, material delivery, and production status. More importantly, they inform you immediately of any potential issues or delays, along with a proposed solution.

- Responsiveness and Accessibility: When you have a question or concern, how quickly and thoroughly do they respond? Assess their communication style during the initial quoting phase. Are they quick to reply? Do they answer your questions clearly? This early interaction is often a good indicator of how they will behave once they have your business.

- Language and Cultural Alignment: Especially when working with overseas manufacturers, ensure there are no significant language barriers. The project management team should have fluent English speakers to prevent critical details from getting lost in translation.

Understanding Cost and Overall Value from Injection Molding Manufacturers

While price is always a factor, the lowest quote is rarely the best value. A quote that seems too good to be true often hides future costs in the form of poor quality, delays, or unexpected charges. The goal is to find a partner who offers the best total cost of ownership (TCO).

- Detailed, Transparent Quoting: A professional quote should be fully itemized. It should clearly break down the tooling cost (the mold) and the unit part price. Be wary of quotes that are just a single number. The quote should also specify the material to be used, cycle times, and any assumptions made.

- Tooling Investment: The mold is a significant upfront cost. Inquire about the mold's expected lifespan (number of cycles), the type of steel used, and who owns the tool. In most cases, you pay for the tool, and therefore you should own it. A cheap mold made from low-grade materials may save money initially but will wear out quickly, leading to quality issues and the need for a costly replacement.

- Cost vs. Quality: The cost of a bad part is always higher than the cost of a good part. Consider the expenses related to rework, scrap, product returns, and damage to your brand reputation. Investing a little more in a reputable manufacturer with a proven quality record is a wise long-term strategy.

- Landed Cost: When comparing quotes, especially between domestic and overseas options, be sure to calculate the "total landed cost." This includes not only the part price but also shipping, tariffs, customs fees, and insurance.

Reliability and On-Time Delivery with Injection Molding Manufacturers

Your product launch and revenue depend on your manufacturer's ability to deliver quality parts on schedule. Reliability encompasses both consistent quality and dependable delivery timelines.

- Realistic Lead Times: Be skeptical of manufacturers who promise impossibly short lead times. Tooling fabrication is a complex process that takes several weeks at a minimum. A reliable partner will provide a realistic project timeline, including milestones for design approval, tool manufacturing, first article inspection, and mass production.

- On-Time Delivery (OTD) Performance: Ask potential partners about their On-Time Delivery (OTD) rate. A high OTD rate (typically above 95%) indicates they have solid project management and production scheduling systems in place. You can also ask for references to verify their delivery performance.

- Supply Chain Stability: Inquire about their supply chain for raw materials. Do they have multiple approved suppliers for your specified resin? A stable supply chain minimizes the risk of production delays due to material shortages. A manufacturer that is vertically integrated or has strong long-term supplier relationships is generally more reliable.

Frequently Asked Questions (FAQ)

What is the typical lead time for an injection mold?

The lead time for building a new injection mold can vary significantly based on its complexity, size, and the materials used. Generally, you can expect the following timelines:

- Simple, single-cavity prototype molds (often made of aluminum) can be completed in as little as 2-4 weeks.

- Multi-cavity production molds made from P20 steel typically take 5-8 weeks.

- Complex, high-volume molds made of hardened steel (like H13), with features like side-actions, lifters, or unscrewing mechanisms, can take 12-16 weeks or even longer. This timeline covers mold design, material procurement, machining, assembly, and initial sampling. Always confirm the timeline with your chosen manufacturer and ensure it includes the First Article Inspection (FAI) process.

How can I reduce the cost of my injection molded parts?

Several factors influence part cost. You can achieve significant savings by focusing on:

- Design for Manufacturability (DFM): Simplify your design. Eliminate undercuts that require complex mold actions, maintain uniform wall thickness to reduce cycle time and prevent defects, and use generous radii instead of sharp corners.

- Material Selection: Only use an expensive engineering resin if the application absolutely requires it. Often, a less expensive commodity plastic will suffice. Consult with your molder to see if a more cost-effective alternative meets your needs.

- Tolerance Requirements: Only specify tight tolerances where they are functionally necessary. Over-tolerancing a part dramatically increases tooling costs and can lead to higher scrap rates.

- Surface Finish: High-gloss, polished surface finishes (like SPI-A1) require extensive manual labor to prepare the mold and are very expensive. Unless your part is a cosmetic lens, choose a standard or textured finish to save costs.

- Increase Order Volume: Tooling is a fixed cost. The higher your production volume, the lower the amortized tool cost per part will be.

What's the Difference Between Asian and Western Injection Molding Manufacturers?

Choosing between an Asian (e.g., in China, Vietnam, or India) manufacturer and a Western (e.g., in the US or European countries) manufacturer involves a trade-off between cost, logistics, and communication.

- Asian Injection Molding Manufacturers: The primary advantage is typically lower labor costs, which can result in lower tooling and part prices. However, potential downsides include longer shipping times, potential tariffs and customs hurdles, language barriers, different time zones making communication difficult, and challenges in verifying quality or intellectual property protection.

- Western Injection Molding Manufacturers: The main benefits are simplified logistics, faster shipping, easier communication (same language and time zone), stronger IP protection, and the ability to visit the facility easily. The trade-off is often higher labor costs, leading to a higher price point. However, when calculating the total landed cost and considering the risks of delays, the price difference may be smaller than it initially appears.

What file format do I need for my part design?

To get an accurate quote and for manufacturing, you will need to provide two types of files:

- 3D CAD File: This is the most important file. It defines the complete geometry of the part. The most universally accepted formats are STEP (.stp, .step) and IGES (.igs, .iges). Native CAD files from software like SolidWorks (.sldprt), Creo/ProE (.prt), or CATIA are also often acceptable, but STEP files are the best for ensuring compatibility across different systems.

- 2D Drawing: While the 3D model defines the shape, the 2D drawing (usually in PDF format) is used to convey critical information that the 3D model cannot. This includes dimensional tolerances, material specifications, surface finish requirements, thread specifications, and critical-to-quality features. A complete drawing is essential for inspection and quality control.

Conclusion

Selecting the right injection molding manufacturers is a critical decision that extends beyond just price; it involves a comprehensive evaluation of their capabilities, quality systems, communication practices, and overall value. A partnership with the wrong supplier can lead to cascading problems, from poor part quality and production delays to budget overruns and a failed product launch.

By thoroughly assessing your project's unique needs—including volume, material, and complexity—and meticulously vetting potential partners against criteria like technical expertise, quality certifications, and communication effectiveness, you can forge a partnership that ensures high-quality products, efficient production, and a successful market launch for your innovations.

If you are looking for a trusted partner for your next project, we encourage you to get in touch. At SOMI Custom Parts, we pride ourselves on being a trusted partner for injection molding manufacturing services. We leverage a robust and stable supply chain, coupled with advanced equipment and extensive expertise, to deliver high-quality, customized metal and plastic parts. Our commitment to excellence, from prototyping to full-scale production, ensures that we provide efficient and reliable solutions for diverse manufacturing projects.