How Low-Volume Injection Molding Benefits Consumer Electronics Suppliers

- Share

- Issue Time

- Jan 5,2026

Summary

Low-volume injection molding enables rapid prototyping, cost-effective tooling, and agile production for consumer electronics suppliers.

In the fast-paced world of consumer electronics, innovation and speed to market are crucial. Traditional injection molding, while excellent for mass production, often presents hurdles for new product development due to high tooling costs and long lead times. This can stifle creativity and slow the launch of groundbreaking devices that consumers are eagerly awaiting.

This is where low-volume injection molding steps in, offering a transformative solution for consumer electronics suppliers. It bridges the gap between prototyping and large-scale manufacturing, allowing for rapid iteration, cost-effectiveness, and flexibility. By embracing this agile production method, companies can accelerate their development cycles and respond more dynamically to market feedback.

Understanding Low-Volume Injection Molding for Consumer Electronics Suppliers

Low-volume injection molding has emerged as a critical manufacturing process for the consumer electronics industry, providing a strategic advantage for companies looking to innovate quickly. It offers a middle ground, blending the precision of high-volume molding with the flexibility often associated with prototyping methods.

What is Low-Volume Injection Molding?

Low-volume injection molding is a manufacturing process designed to produce plastic parts in smaller quantities, typically ranging from a few hundred up to 100,000 units. Unlike traditional high-volume molding, which is optimized for producing millions of identical parts, this method focuses on efficiency and cost-effectiveness for smaller batches. The core principle is the same: molten plastic is injected into a mold to create a precise part. However, the tooling and machinery are adapted for shorter production runs. This approach is especially useful for producing prototypes, custom-made parts, or for market testing before committing to expensive mass-production tooling. It serves as an essential "bridge-to-production" solution, enabling companies to get high-quality, real-material parts without the massive upfront investment and long lead times of traditional molding.

When is Low-Volume Injection Molding the Right Choice?

Low-volume injection molding is the ideal choice in several key scenarios, particularly for consumer electronics suppliers who need to balance speed, cost, and quality. Determining the right moment to employ this method can provide a significant competitive advantage. It is especially suitable for specialized manufacturing that caters to businesses and industries with smaller production needs.

Here are the primary situations where low-volume injection molding is the best option:

Rapid Prototyping and Design Validation: When you have a mature design that needs to be tested for form, fit, and function, low-volume molding is perfect. It allows you to create functional prototypes from production-grade materials, providing far more accurate real-world feedback than 3D printing alone. This helps validate a design before committing to the high costs of mass production tooling.

Market Testing and Pilot Runs: Before launching a new electronic device, it's crucial to gauge consumer interest. Low-volume molding allows companies to produce a small batch of products for market testing or a limited-edition release. This strategy minimizes financial risk while gathering valuable feedback to refine the product or marketing strategy.

Bridge-to-Production: Sometimes, there's a gap between finalizing a design and setting up high-volume production lines, which can take months. Low-volume molding acts as a "bridge," allowing you to start manufacturing and selling your product while the more expensive and durable steel molds for mass production are being prepared.

Niche Products and Customization: The consumer electronics market has a growing demand for customized and niche products. Low-volume molding is perfectly suited for producing limited runs of devices with special colors, features, or branding. It makes manufacturing products with limited or specialized demand economically feasible.

Projects with Unpredictable Demand: For startups or new product lines, predicting future sales volume can be difficult. Low-volume injection molding reduces financial risk when demand is uncertain. It provides a cost-effective way to enter the market without a massive upfront investment in tooling that might become obsolete if the product doesn't succeed or needs design changes.

Frequent Design Iterations: In the fast-evolving electronics industry, products are constantly updated. Low-volume tooling, often made from aluminum, can be modified more quickly and cheaply than hardened steel tools. This makes it ideal for products that undergo frequent design changes or version updates.

Common Injection Molded Small Parts in Consumer Electronics

The intricate and compact nature of modern consumer electronics relies heavily on small, high-precision plastic components. Low-volume injection molding is an ideal manufacturing method for producing these parts, ensuring quality and consistency even in smaller batches.

Plastic Snap Fittings

Plastic snap fittings are a cornerstone of modern consumer electronics design, offering a fast and efficient method for assembling components without screws or adhesives. These fittings work by using the natural flexibility of plastic; a protrusion on one part, often called a hook or bead, deflects during assembly and "snaps" securely into a corresponding recess on the mating part. This creates a strong, interlocking connection that simplifies manufacturing and reduces the number of individual parts.

The most common type is the cantilever snap-fit, which features a small flexible beam that locks into place. These are found everywhere from battery compartment covers to the main enclosures of devices like remote controls and smart home hubs. The design of these fittings is critical, as they must withstand the stress of assembly and, in some cases, repeated disassembly. Materials like ABS, Polycarbonate (PC), and Nylon are often chosen for their balance of strength, flexibility, and fatigue resistance, making them ideal for these applications. Low-volume injection molding is perfectly suited to produce these intricate features with high precision, allowing for rapid design adjustments and testing to ensure a perfect fit.

Plastic Caps and Hinges

Plastic caps and hinges are ubiquitous in consumer electronics, serving both functional and protective roles. Caps are essential for protecting sensitive ports—like USB-C, headphone jacks, and charging connectors—from dust, moisture, and physical damage. Hinges, on the other hand, provide articulation for device components, such as the flip-out screens on cameras or the lids on portable charging cases.

A particularly innovative type of hinge that is perfect for injection molding is the "living hinge." A living hinge is a very thin, flexible web of plastic that connects two larger, rigid sections, all molded as a single piece. This design eliminates the need for separate hinge components and assembly, significantly reducing costs and simplifying production. Living hinges are extremely durable and can withstand thousands of cycles without breaking. Materials like Polypropylene (PP) and Polyethylene (PE) are ideal for living hinges due to their excellent fatigue resistance. Low-volume injection molding allows for precise control over the hinge's thin geometry, which is critical for its flexibility and longevity, making it a cost-effective solution for producing parts with these integrated features.

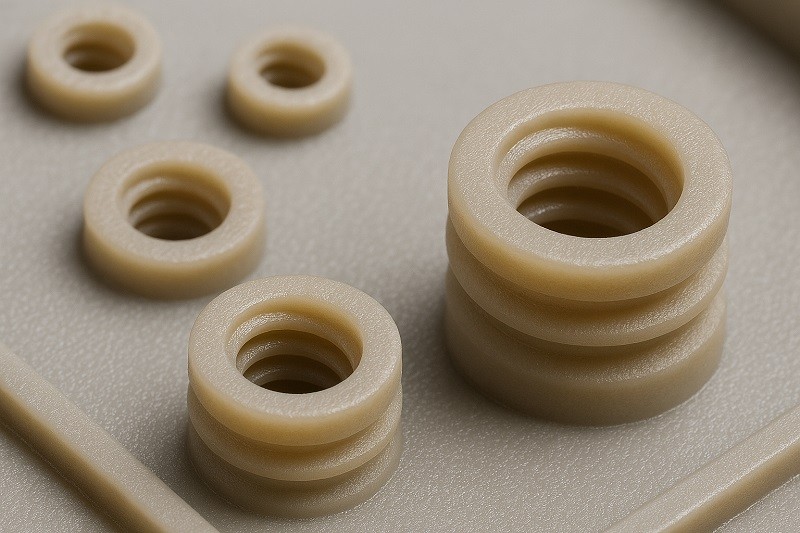

Small Threaded Components

Incorporating threaded features directly into molded plastic parts is a highly efficient way to create secure fastening points in consumer electronics. This eliminates the need for separate metal nuts or inserts, reducing component count, assembly time, and overall cost. Injection molding can produce both external threads (like those on a bottle cap) and internal threads (for accepting screws).

Creating successful molded threads requires careful design. For example, plastic threads are generally more susceptible to stripping than their metal counterparts, so designers often use a coarser pitch and rounded thread profiles to increase strength. For internal threads, the molding process is more complex as it requires a mechanism to unscrew the threaded core from the part after the plastic has solidified. This can be done manually for very low volumes or with fully automatic unwinding mechanisms for larger runs.

Despite the complexities, the benefits are substantial. Materials like ABS, Nylon, and POM (Delrin) are excellent choices for threaded components due to their strength and low friction. Low-volume injection molding provides a cost-effective way to produce these parts, allowing for testing and refinement of the thread design to ensure a perfect balance of fastening strength and manufacturability.

The Key Advantages of Low-Volume Injection Molding for Consumer Electronics Suppliers

In the hyper-competitive consumer electronics market, gaining an edge often comes down to efficiency, speed, and intelligent cost management. Low-volume injection molding offers a powerful combination of benefits that directly address these critical needs, making it an indispensable tool for innovative suppliers. By leveraging this process, companies can navigate the product development lifecycle with greater agility and financial prudence.

The inherent advantages of this manufacturing method empower electronics suppliers to launch products faster, reduce financial risks, and maintain the high-quality standards that consumers expect. This strategic approach is reshaping how electronic devices are designed, tested, and brought to market.

Cost-Effectiveness and Reduced Tooling Costs

One of the most significant barriers to new product development in injection molding is the high upfront cost of tooling. Traditional high-volume production requires molds made from hardened steel, which are incredibly durable but can cost tens or even hundreds of thousands of dollars and take months to fabricate.

Low-volume injection molding provides a much more cost-effective alternative by primarily using molds made from high-grade aluminum. Aluminum is softer than steel, which makes it significantly faster and cheaper to machine. This can reduce initial tooling costs by 30-50% or more compared to steel. For startups and companies developing niche products, this drastic reduction in upfront investment is a game-changer, making it financially viable to bring new ideas to life. Although aluminum molds have a shorter lifespan than steel, they are perfectly suited for production runs of up to 10,000+ parts, which is ideal for prototyping, market testing, and bridge production.

| Feature | Low-Volume (Aluminum) Tooling | High-Volume (Steel) Tooling |

|---|---|---|

| Initial Cost | Low (thousands of dollars) | High (tens to hundreds of thousands) |

| Lead Time | Fast (days to weeks) | Slow (months) |

| Mold Lifespan | 100 - 10,000+ cycles | 100,000 - 1,000,000+ cycles |

| Best For | Prototyping, bridge production, niche markets | Mass production, stable designs |

| Design Flexibility | High (easier and cheaper to modify) | Low (expensive and time-consuming to modify) |

Rapid Turnaround Times and Flexibility

In the consumer electronics industry, speed is paramount. The ability to move a product from concept to market quickly can be the difference between leading a trend and chasing it. Low-volume injection molding is a key enabler of this speed, offering significantly faster turnaround times compared to traditional manufacturing. Because molds are typically made from aluminum, which is easier to machine, the time from final design to first part-in-hand can be reduced from months to just a few weeks.

This rapid tooling process gives suppliers unparalleled flexibility. When design flaws are discovered or market feedback suggests a change, aluminum molds can be modified quickly and inexpensively. This facilitates an agile development process, allowing for multiple design iterations in a short period. This flexibility is crucial for continually improving a product without the massive financial penalties associated with altering hardened steel tooling. Consequently, companies can bring better, more refined products to market faster, gaining a crucial competitive advantage.

High Quality and Precision for Consumer Electronics Components

A common misconception is that "low-volume" implies lower quality. In reality, low-volume injection molding utilizes the same core principles and production-grade thermoplastic materials as high-volume manufacturing. This means the resulting components exhibit excellent mechanical properties, dimensional accuracy, and consistency. For consumer electronics—where parts must fit together perfectly for both function and aesthetics—this precision is non-negotiable.

The process is capable of achieving very tight tolerances, often in the range of ±0.05mm to ±0.1mm, which is critical for complex assemblies like smartphone casings and internal component mounts. Furthermore, aluminum molds boast superior thermal conductivity compared to steel, which allows for more uniform cooling. This often results in parts with better dimensional stability and less warpage.

The surface finish of the parts is also a key advantage. The finish of the final part is a direct transfer from the mold surface. Molds can be textured or polished to a high gloss, allowing for a wide range of aesthetic options, from matte textures that hide fingerprints to glossy, premium finishes. This attention to detail ensures that parts are not only functional but also meet the high cosmetic standards of the consumer electronics market.

Material Versatility and Design Freedom

One of the greatest strengths of low-volume injection molding is the ability to use a vast range of production-grade thermoplastic materials. This allows engineers and designers to create prototypes and end-use parts with the exact material properties required for the final product—a significant advantage over other prototyping methods like 3D printing, which often rely on materials that only simulate the desired characteristics.

This material versatility gives suppliers the freedom to test and validate components under real-world conditions. For example, a supplier can produce batches of an electronic housing in both standard ABS for cost-effectiveness and a stronger PC/ABS blend for enhanced impact resistance. By testing these different materials early in the development cycle without committing to expensive, high-volume tooling for each, companies can make informed decisions that optimize both performance and cost.

Furthermore, this flexibility translates directly into greater design freedom. Designers are not constrained by limited material choices and can create parts with intricate geometries, fine details, and complex features like undercuts or threads. This capability is crucial in the consumer electronics space, where aesthetics and compact, integrated designs are key selling points. Low-volume injection molding empowers designers to push creative boundaries and iterate quickly, ensuring the final product is not only manufacturable but also innovative and highly functional.

Techniques and Considerations for Consumer Electronics Injection Molding Suppliers

To master low-volume injection molding for consumer electronics, suppliers must navigate a series of critical techniques and considerations. From the initial material choice to the intricacies of the molding process itself, each step plays a vital role in creating high-quality, reliable, and cost-effective components. Success hinges on a deep understanding of how these elements interact to meet the demanding standards of the electronics industry.

Material Selection: Optimizing for Performance and Durability

Choosing the right plastic is one of the most critical decisions in the manufacturing of consumer electronics. The material must not only meet the functional requirements of the part but also be optimized for the injection molding process. Key factors to consider include:

- Electrical Insulation: For most housings and internal components, strong dielectric properties are essential to prevent electrical leakage and ensure user safety.

- Heat Resistance: Many electronic devices generate significant heat. Materials must have a high enough heat deflection temperature (HDT) to resist warping or melting during operation.

- Impact Resistance and Durability: Devices can be dropped or subjected to mechanical stress. Tough, impact-resistant plastics are necessary to protect delicate internal components.

- Aesthetic and Brand Requirements: The material should support the desired look and feel of the product, including color, texture, and finish, to enhance brand identity.

- Regulatory Compliance: Depending on the application, materials may need to meet standards like UL for flammability or RoHS for hazardous substances.

Common Plastics in Consumer Electronics:

| Material | Key Properties & Common Uses |

|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Good all-around performance with excellent toughness and impact strength. Ideal for housings, keyboards, and phone cases. |

| PC (Polycarbonate) | Superior impact strength (up to 250 times stronger than glass) and high heat resistance. Often used for transparent enclosures, displays, and rugged devices. |

| PC/ABS Blend | Combines the strength and heat resistance of PC with the flexibility and processability of ABS. Widely used in laptop casings and telecom devices. |

| PBT (Polybutylene Terephthalate) | Excellent electrical insulation, and chemical and heat resistance. A common choice for connectors, switches, and sockets. |

| Nylon (Polyamide / PA) | High mechanical strength, temperature stability, and wear resistance. Used for structural components and gears. |

| PMMA (Acrylic) | High optical clarity and weather resistance. Perfect for display screens, light pipes, and decorative lenses. |

Low-volume injection molding provides the perfect platform for testing these materials in small, cost-effective batches to find the optimal balance between performance, cost, and manufacturability before committing to large-scale production.

Mold Design: Efficiency and Iteration

Effective mold design is a blend of art and science, and it becomes even more critical in the context of low-volume production, where efficiency and the ability to iterate are paramount. The goal is to create a tool that is not only cost-effective to produce but also robust enough to deliver high-quality parts consistently. A key strategy in achieving this is through Design for Manufacturability (DFM).

DFM is the process of designing parts in a way that makes them as easy and economical to manufacture as possible. In low-volume injection molding, DFM analysis helps identify potential issues before the mold is ever created, saving significant time and money. Some core DFM principles for mold design include:

- Draft Angles: All vertical walls of a part should be slightly angled (typically 1-2 degrees) to facilitate smooth ejection from the mold. Without proper draft, parts can be scratched or damaged during removal, and it increases wear on the mold itself.

- Uniform Wall Thickness: Maintaining a consistent wall thickness throughout the part is crucial. Thicker sections cool slower than thinner ones, which can lead to defects like sink marks, warping, and internal stresses.

- Radii and Corners: Sharp internal corners create stress concentrations, which can become weak points in the final part. Incorporating a radius at these corners helps the molten plastic flow more smoothly and distributes stress more evenly.

- Gate and Runner Design: The placement and size of gates (where plastic enters the mold cavity) are critical for ensuring the cavity fills completely and evenly. Poor gate design can lead to cosmetic defects and structural weaknesses.

Because low-volume molds are faster and cheaper to produce, they actively encourage design iteration. Engineers can quickly receive feedback from a DFM report, make adjustments to the CAD model, and even create a modified or new tool without the prohibitive costs associated with steel molds. This iterative loop is what allows for the rapid refinement and perfection of a part before committing to mass production.

The Injection Process: Precision and Repeatability

The physical process of injection molding is a carefully orchestrated sequence where precision and control are paramount to ensuring shot-to-shot consistency. Achieving this repeatability is crucial for consumer electronics, where even minor variations can affect the fit, function, and feel of the final product. Suppliers must master several key process parameters to guarantee high-quality outcomes.

The injection molding cycle can be broken down into several stages, with the filling, packing, and cooling phases having the most significant impact on part quality. Key parameters that are meticulously controlled include:

- Temperature (Melt and Mold): The plastic resin must be heated to the optimal melt temperature to ensure it flows smoothly and evenly into the mold cavity. The mold temperature itself is also critical; it influences how quickly the part solidifies, which affects everything from surface finish to internal stresses and shrinkage. Consistent temperature control is vital for quality.

- Injection Pressure and Speed: Injection pressure is the force used to push the molten plastic into the mold. It must be high enough to fill the entire cavity completely, preventing defects like short shots. Injection speed, the rate at which the material is injected, affects the fill pattern and is key to avoiding issues such as flow lines and air traps.

- Holding Pressure and Time: After the initial injection, a holding pressure is applied. This packs additional material into the cavity to compensate for the natural shrinkage that occurs as the plastic cools. The duration and level of this pressure are fine-tuned to prevent voids and sink marks, ensuring the part is dense and dimensionally stable.

- Cooling Time: The cooling phase is often the longest part of the entire molding cycle, accounting for up to 80% of the total time. It's the period where the part solidifies enough to be ejected without deforming. The cooling rate must be uniform to prevent warping and internal stresses.

By implementing advanced process control systems and leveraging scientific molding principles, suppliers can monitor these variables in real-time. This ensures that every part produced, from the first to the last in a batch, adheres to the same strict specifications, guaranteeing the repeatability essential for high-quality consumer electronics.

Types of Injection Molding Applicable to Consumer Electronics

The versatility of injection molding extends beyond the standard process. Several specialized techniques have been developed to create parts with unique characteristics, many of which are essential for the advanced design and functionality of modern consumer electronics.

Conventional Injection Molding

Conventional injection molding, often called single-shot molding, is the most common and foundational technique in the plastics industry. It's a highly efficient process for mass-producing identical parts from a single thermoplastic material.

The process is straightforward and cyclical:

- Clamping: The two halves of the mold are clamped together under high pressure.

- Injection: Plastic pellets are melted in a heated barrel and then injected under high pressure into the mold cavity.

- Cooling: The molten plastic cools and solidifies, taking the shape of the mold.

- Ejection: The mold opens, and the finished part is pushed out.

This method is the backbone of manufacturing for a vast array of consumer electronic components, including single-piece housings, buttons, internal brackets, and battery trays. Its primary advantages are speed, repeatability, and a very low cost per part once the initial tooling investment is made. While it is the standard for high-volume production, the same fundamental process is used in low-volume molding, delivering production-quality parts but with the added benefits of lower tooling costs and faster turnarounds.

Overmolding and Insert Molding

Overmolding and insert molding are two advanced manufacturing techniques that create robust, multi-material components in a single, streamlined process. Both are invaluable for producing the complex and highly integrated parts found in today's consumer electronics. While similar, they have distinct differences and applications.

Insert Molding is a process where a pre-formed component, or "insert"—often made of metal, such as a threaded fastener, a pin, or an electrical contact—is placed into the mold before the molten plastic is injected. The plastic then flows around the insert, permanently encapsulating it and creating a strong mechanical bond.

- Benefits & Applications: This method is ideal for creating durable parts with enhanced strength and functionality. In consumer electronics, it's widely used to embed metal threaded inserts into plastic housings for screw attachments, mold connectors directly onto cables for strain relief, and secure electrical contacts within sensors and switches. This eliminates the need for post-molding assembly steps like gluing or pressing in inserts, which reduces labor costs and creates a more reliable part.

Overmolding, on the other hand, is typically a two-step process. First, a rigid base part (the substrate) is molded. Then, this substrate is placed into a second mold, and a different material—usually a soft, flexible thermoplastic elastomer (TPE)—is injected over, around, or through the original part.

- Benefits & Applications: Overmolding is perfect for adding ergonomic or aesthetic features to a product. The most common application in consumer electronics is creating soft, non-slip grips on devices like remote controls, game controllers, and power tools. It is also used to create integrated gaskets and seals for water resistance, add protective bumpers to device corners, and combine different colors for branding and visual appeal. The process creates a strong chemical or mechanical bond between the two materials, resulting in a seamless, unified final product.

|

|

|---|---|

| Insert Molding Example | Overmolding Example |

Both techniques showcase the advanced capabilities of injection molding, allowing for the creation of highly functional, durable, and sophisticated electronic components efficiently.

Gas-Assisted and Liquid Silicone Injection Molding

Gas-Assisted Injection Molding

Gas-assisted injection molding is a low-pressure process where, after the mold is partially filled with molten plastic, pressurized nitrogen gas is injected. This gas creates hollow channels within the thicker sections of the part, pushing the plastic outwards against the mold walls.

- Benefits & Applications: This technique is excellent for producing large, lightweight, yet strong components with excellent surface finishes. It allows for the design of parts with both thick and thin sections without the risk of common defects like sink marks or warping. For consumer electronics, it's ideal for manufacturing large housings for monitors, printers, or game consoles, as well as complex, structurally sound parts like handles or support brackets. The process saves material, reduces part weight, and can shorten cycle times as the hollow sections cool faster.

Liquid Silicone Rubber (LSR) Injection Molding

Liquid Silicone Rubber (LSR) molding is a specialized process that uses a two-part platinum-cured silicone that is mixed and then injected into a heated mold where it vulcanizes (cures). This is distinct from conventional thermoplastic molding, which involves melting solid pellets.

- Benefits & Applications: LSR offers a unique combination of properties that make it invaluable for electronics. It is extremely durable, flexible, and maintains its properties over a wide range of temperatures (often from -50°C to over 200°C). LSR is also biocompatible, water-repellent, and has excellent electrical insulation properties. These characteristics make it the perfect material for soft, pliable components like keypad buttons, waterproof seals and gaskets for rugged devices, flexible cable strain reliefs, and protective covers for connectors. The process allows for high-precision, flashless molding of very intricate parts, which is essential for the compact design of modern electronics.

Applications and Industry Impact: How Low-Volume Consumer Electronics Injection Molding is Changing the Game

The shift toward low-volume injection molding is fundamentally altering the landscape of the consumer electronics industry. By providing an agile, cost-effective, and high-quality manufacturing solution, it empowers companies of all sizes to innovate more freely and compete more effectively. This method bridges the critical gap between initial concept and mass market, profoundly impacting the entire product development lifecycle.

Prototyping and New Product Development

Traditionally, prototyping for new product introduction (NPI) has been a balancing act between the speed of 3D printing and the cost of production tooling. Low-volume injection molding offers the best of both worlds, revolutionizing the prototyping phase. While 3D printing is excellent for creating initial form-fit models quickly and cheaply, it often uses materials that only simulate the properties of the final product and can lack strength and surface finish.

Low-volume injection molding, however, allows for the creation of functional prototypes using the actual production-grade thermoplastic materials. This is a game-changer for several reasons:

- Real-World Testing: Prototypes made with the final material can undergo rigorous functional, environmental, and stress testing, providing accurate data on how the part will perform in the hands of consumers.

- Superior Quality: Injection-molded prototypes have the density, strength, and surface finish of a final product, giving stakeholders a true representation of the device. This is crucial for securing buy-in and making critical design decisions.

- Accelerated Development: By enabling more realistic testing earlier in the process, potential flaws in design, material choice, or manufacturability can be identified and corrected quickly, accelerating the overall product development timeline.

This method effectively serves as a bridge from prototyping to full production, enabling a smoother transition and reducing the risks associated with scaling up.

Meeting Niche Market Demands

The consumer electronics market is no longer a one-size-fits-all world. Today's consumers crave personalization, unique features, and products tailored to specific interests. This has created a surge in demand for niche and customized electronic devices, a trend that traditional mass-production models struggle to accommodate economically.

Low-volume injection molding is the ideal solution for this challenge. Its low upfront tooling costs and flexibility make it financially viable to produce small batches of specialized products. This empowers companies to:

- Launch Limited-Edition Products: A brand can easily produce a run of its popular headphones or smartwatches in a unique, limited-time colorway or with special branding for an event.

- Serve Niche Hobbies and Professions: The demand for specialized equipment in fields like professional photography, competitive gaming, or field biology can be met by creating custom-designed devices in smaller quantities.

- Offer Customization Options: Low-volume manufacturing allows companies to offer customers a range of personalized choices, such as custom-engraved casings or different material finishes, without the risk of producing large amounts of unsold inventory.

- Test New Features: Established brands can use low-volume runs to introduce and test new features on existing product lines with a select audience before a wider rollout, gathering valuable feedback while minimizing risk.

By enabling cost-effective, small-batch production, low-volume manufacturing allows both startups and established corporations to explore new market segments, respond to specific consumer desires, and create a more diverse and interesting product landscape.

Improving Design Iteration and Rapid Production Cycles for Consumer Electronics

The consumer electronics industry operates on razor-thin deadlines and constantly evolving consumer expectations. In this environment, the ability to iterate on a design quickly and move into production rapidly is not just an advantage—it's a necessity. Low-volume injection molding is a key driver of this agile product development process.

The speed of this method stems directly from its use of more easily machinable molds, typically made from aluminum. These "rapid tools" can be created in a fraction of the time it takes to produce hardened steel molds for mass production. This shortens the entire production cycle, allowing companies to:

- Accelerate the Feedback Loop: Designers and engineers can get physical, production-quality parts in their hands within weeks. This allows for rapid testing, validation, and the identification of design flaws.

- Enable Agile Iteration: Because the tools are less expensive and faster to modify, making design changes is no longer a catastrophic cost or delay. If testing reveals a weakness or a potential improvement, the mold can be adjusted and a new batch of improved parts can be produced quickly. This iterative process, which is central to agile development, leads to a more refined and robust final product.

- Reduce Time-to-Market: By compressing the prototyping and validation phases, low-volume injection molding helps companies launch their products faster. This ability to quickly seize market opportunities is a significant competitive advantage in the fast-paced electronics sector.

Essentially, low-volume molding removes the traditional bottlenecks of tooling, allowing for a more fluid and responsive production cycle that moves at the speed of innovation.

Examples in Consumer Electronics: From Cases to Internal Components

The impact of low-volume injection molding is visible across the entire spectrum of consumer electronics. Its versatility and precision make it the ideal manufacturing method for a wide array of components, from external housings to critical internal parts. This adaptability has allowed for greater innovation and a faster product development cycle in a very competitive market.

Here are just a few examples of how it's being applied:

Smartphone Cases and Housings: The process is perfect for producing protective and stylish smartphone cases. Injection molding allows for intricate designs, precise cutouts for cameras and ports, and consistent quality. It is the most common method for creating cases from a variety of materials, including tough Polycarbonate (PC), flexible TPU, and durable PC/ABS blends.

Wearable Technology: The market for wearables like smartwatches, fitness trackers, and smart rings demands components that are compact, lightweight, and comfortable for prolonged skin contact. Injection molding, including specialized techniques like Liquid Silicone Rubber (LSR) molding and overmolding, is used to create everything from flexible, biocompatible silicone watch bands to durable, water-resistant housings for fitness trackers. The precision of the process is critical for producing these tiny, intricate parts.

Drone Components: Drones require parts that are both incredibly lightweight and structurally robust to ensure aerodynamic efficiency and durability. Low-volume injection molding is used to produce many of these components, including propeller blades, protective propeller guards, battery housings, and the main body shells or enclosures. Materials like carbon fiber-reinforced plastics are often used to achieve a high strength-to-weight ratio.

Internal Components and Connectors: Beyond what's visible on the outside, injection molding is crucial for producing a vast number of internal parts. These include internal structural frames, mounts for circuit boards, buttons, switches, and a wide variety of connectors (USB, HDMI, etc.). The high precision of molding ensures these components fit perfectly, which is essential for the proper function and reliability of the electronic device.

By enabling the cost-effective production of these diverse components, low-volume injection molding empowers electronics suppliers to test, refine, and launch a wider range of innovative products more efficiently than ever before.

Conclusion

Low-volume injection molding is undeniably a game-changer for consumer electronics suppliers, offering a pathway to faster innovation, reduced costs, and superior product quality without the typical constraints of traditional manufacturing. It provides the perfect blend of agility and precision, allowing companies to respond to market demands quickly while ensuring their products meet the highest standards of performance and aesthetics.

By embracing this versatile manufacturing method, companies can bring groundbreaking electronic devices to market more efficiently and with greater confidence. SOMI Custom Parts, a trusted injection molding supplier, is dedicated to assisting businesses in leveraging these advantages to achieve their product development goals. Whether for prototyping, niche market entry, or bridge production, this approach paves the way for a more dynamic and successful future in the ever-evolving world of consumer electronics. We encourage you to share this article and discuss how these techniques could revolutionize your own production strategies.