How Custom Metal Stamping Services Deliver Precision Parts

- Share

- Issue Time

- Dec 12,2025

Summary

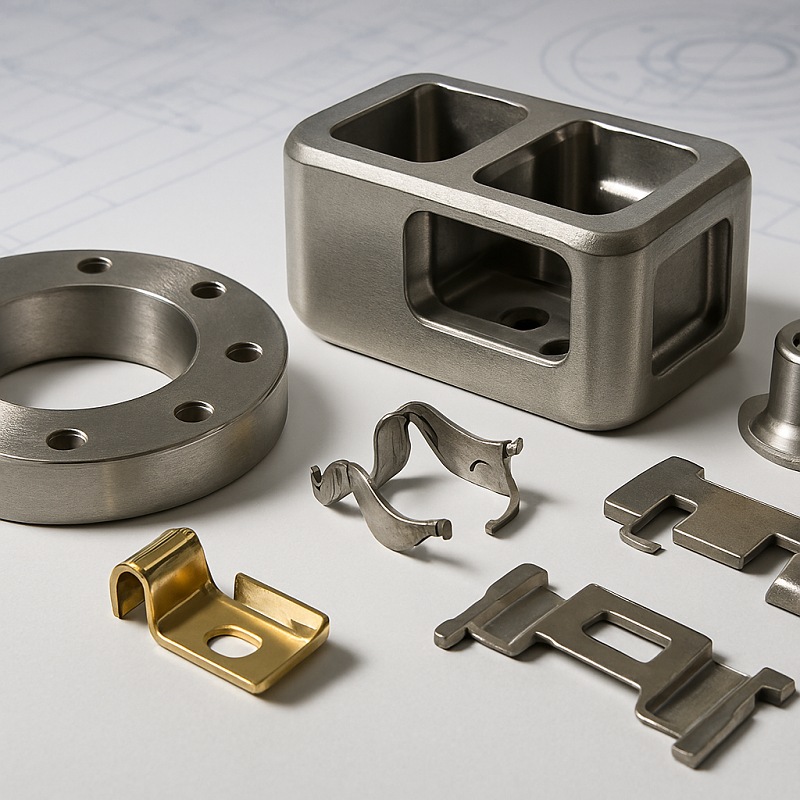

Custom metal stamping services are fundamental in modern manufacturing, enabling the precise and efficient production of components across diverse industries. This process involves shaping flat metal sheets into specific forms using specialized dies and presses, ensuring consistent quality even for complex geometries.

As an expert in manufacturing, I've seen firsthand how custom metal stamping services have revolutionized the production of precise parts across diverse industries. From tiny medical implants to robust automotive components, metal stamping offers unparalleled accuracy and efficiency. This process involves shaping flat metal sheets into specific forms using specialized dies and presses, ensuring consistent quality even for complex geometries.

The demand for high-precision components continues to grow, making custom metal stamping an increasingly vital manufacturing method. We'll explore how these services deliver exceptional precision, maintain stringent quality standards, and offer significant cost advantages, ultimately transforming how businesses acquire their critical components.

The Unmatched Precision of Custom Metal Stamping Services

The core value of custom metal stamping lies in its ability to produce parts with an extraordinary degree of precision. In sectors where even microscopic deviations can have significant consequences, this manufacturing process stands out for its accuracy and consistency. It’s a technology that combines powerful machinery with meticulous engineering to turn raw metal into perfectly formed components, time after time. This reliability is not just a goal but a fundamental requirement, especially for safety-critical applications in the aerospace, automotive, and medical fields.

Achieving Micro-Level Accuracy

Micro-level accuracy in metal stamping is the result of a synergistic relationship between advanced machinery, superior tooling, and expert process control. It's about more than just shaping metal; it's about controlling material flow, managing stress, and maintaining dimensional stability at a microscopic level. Modern stamping operations can achieve tolerances that were once considered impossible, making it a go-to method for manufacturing the smallest and most intricate components with confidence.

Handling Complex Geometries and Tight Tolerances

One of the defining features of custom metal stamping is its capability to produce parts with highly complex geometries while holding exceptionally tight tolerances. The process is a complex operation that uses a combination of presses and dies to transform sheet metal into specific, often intricate, shapes. This allows for the creation of components that feature deep draws, sharp angles, narrow curves, and other three-dimensional forms that would be difficult or impossible to achieve with other methods.

Advanced techniques like progressive die stamping, where a series of operations are performed sequentially, and multi-slide stamping, which can form parts from multiple axes, enable the creation of incredibly detailed parts with little waste. Manufacturers can now achieve dimensional tolerances controllable to ±0.05mm or even tighter, ensuring parts fit together seamlessly in final assemblies. Some specialized services even maintain tolerances as tight as 0.0005 inches by engineering and building their own die and tool sets in-house. This level of precision is critical in industries where performance is directly tied to the exactness of each component.

The Role of Advanced Technology in Precision

Advanced technology is the engine that drives modern precision metal stamping. Technologies like servo-driven presses, Computer-Aided Design (CAD), and in-die sensor systems have revolutionized the industry.

Servo Press Technology: Unlike traditional mechanical presses, servo-driven presses offer unparalleled control over the stamping stroke. They allow for adjustments in press speed and force throughout the process, enabling better metal flow, higher accuracy, and the ability to form advanced high-strength materials effectively. This precise control is key to creating complex shapes and minimizing material stress.

CAD/CNC and In-House Tooling: Modern CAD systems have streamlined the entire process, from initial part design to the manufacturing of the custom tools and dies needed for production. When a company manages its tooling design and fabrication in-house using state-of-the-art CNC machining, it gains complete control over quality and can ensure the dies are built for precision and durability. This vertical integration is a hallmark of high-end stamping services.

Smart Manufacturing and Automation: The integration of Industry 4.0 principles, such as placing sensors directly within stamping dies, allows for real-time data collection and process monitoring. This data helps operators monitor machine temperature, pressure, and other critical parameters, allowing for immediate adjustments to maintain consistency and predict maintenance needs before they cause defects.

The following table summarizes how these technologies contribute to overall precision:

| Technology | Contribution to Precision | Key Benefits |

|---|---|---|

| Servo Presses | Precise control over ram speed and position. | Better metal flow, ability to form complex shapes, higher repeatability. |

| CAD/CNC Machining | Enables highly accurate and complex tool and die design. | Faster prototyping, custom tooling, tighter tolerances. |

| In-Die Sensors | Real-time monitoring of the stamping process. | 100% verification of critical features, reduced scrap, predictive maintenance. |

| Automation/Robotics | Automates material handling and inspection. | Increased speed, reduced human error, enhanced consistency. |

Ensuring Consistency and Repeatability

In high-volume manufacturing, precision is meaningless without repeatability. Custom metal stamping excels at producing identical components from the first part to the millionth. This consistency is fundamental to mass production, as it ensures that every component will perform its function flawlessly and fit perfectly into larger assemblies. Inconsistent parts can lead to assembly line disruptions, product defects, and even safety hazards, making repeatability a non-negotiable aspect of quality manufacturing.

Achieving this level of consistency depends on several critical factors:

- Precision-Engineered Tooling: Repeatability begins with the die. High-quality, robust dies made from durable materials like tool steels are essential for maintaining tight tolerances over millions of strokes. A company that builds and maintains its own tooling has a significant advantage, as it can optimize the die for longevity and ensure it stays within specification throughout the entire production lifecycle.

- Strict Process Control: Documented setup procedures and rigorous in-process inspections are vital. Skilled operators who understand the nuances of the stamping process can make real-time adjustments to maintain quality. Furthermore, automated systems maintain consistent operational parameters like speed and pressure, which drastically reduces the risk of human error.

- Material Uniformity: The process starts with the raw material. Using uniform, high-quality metal coils with consistent thickness, hardness, and chemical composition ensures predictable performance during stamping and prevents dimensional inaccuracies.

- Regular Maintenance: Over time, tools inevitably wear down. A proactive preventive maintenance program that tracks tool usage and schedules regular servicing is crucial to prevent defects before they occur. This practice preserves part quality and minimizes costly production downtime.

By mastering these elements, custom metal stamping services provide the unwavering consistency that modern industries demand, ensuring product integrity and operational efficiency.## Custom Metal Stamping Services for Diverse Industry Needs

The versatility of custom metal stamping allows it to serve a vast array of industries, each with its own unique set of challenges and stringent requirements. From life-saving medical devices to mission-critical aerospace components, this manufacturing process provides the precision, reliability, and quality necessary to meet the highest standards. The ability to work with a wide range of materials and produce parts in high volumes makes it an indispensable part of modern supply chains across the globe.

Medical Devices: Life-Saving Precision

In the medical device industry, there is no room for error. Components must be manufactured to exceptionally high standards to ensure they are safe, reliable, and effective for patient care. Metal stamping is a critical process for producing a wide range of medical components, from tiny parts for implantable devices to complex surgical instruments.

- Strict Quality and Compliance: Medical stamping requires adherence to rigorous standards, such as those outlined by ISO 13485. This certification ensures that every part meets or exceeds the strict requirements for medical devices. Good Manufacturing Practice (GMP) is also applied to ensure products are consistently produced and controlled.

- Specialty Materials: Medical components are often made from biocompatible and corrosion-resistant materials that can be easily sanitized. Stamping services for this sector have experience working with a variety of specialty metals, including medical-grade stainless steel, titanium, platinum iridium, and MP35N.

- Wide Range of Applications: Stamped parts are found in countless medical applications, such as surgical instruments, implants and prosthetics, insulin pumps, pacemakers, and diagnostic equipment. Examples include micro-miniature parts for hearing aids, clips and clamps for surgical procedures, and shielding components for electronic medical devices.

Aerospace and Military: Uncompromising Reliability

For the aerospace and military sectors, component failure is not an option. Parts must function flawlessly in extreme environments, from the high altitudes of commercial airliners to the harsh conditions of a battlefield. Metal stamping delivers the strength, precision, and durability required for these mission-critical applications.

- Meeting Stringent Specifications: Parts manufactured for military and defense use must comply with stringent military specifications (Mil-Spec), which include tight dimensional tolerances and the ability to withstand extreme temperatures and stress. This ensures standardization and reliability across all suppliers.

- Advanced and Exotic Materials: The aerospace and defense industries often require components made from high-strength, lightweight, and corrosion-resistant alloys. Stamping specialists in this field have extensive experience with materials like titanium, Inconel, stainless steel alloys, and other exotic metals that can perform under the harshest conditions.

- Critical Applications: Stamped components are integral to a wide range of aerospace and defense systems. They can be found in commercial aircraft, military jets, missiles, and ground vehicles. Specific examples include brackets, connectors, engine components, armor, munitions parts, and housings for sensitive electronics and communication systems.

Electronics and Automotive: High-Volume Excellence

The electronics and automotive industries are characterized by their need for high-volume production runs of extremely precise and consistent parts. Metal stamping is the ideal manufacturing process for these sectors, offering a cost-effective and highly efficient method for producing millions of identical components with short turnaround times.

Electronics Industry: As electronic devices become smaller and more complex, the demand for miniature metal components is rapidly expanding. Stamping is used to create a vast array of electronic parts, including:

- Connectors, Terminals, and Contacts: These facilitate electrical connections in everything from smartphones to home appliances.

- EMI/RFI Shielding: Stamped shields protect sensitive electronic components from electromagnetic and radio-frequency interference.

- Housings and Brackets: These provide structural integrity and protection for electronic assemblies.

- Semiconductor Components: The process is also used to make critical parts for semiconductor manufacturing, such as components for wafer handling and die packaging.

Automotive Industry: Metal stamping is a cornerstone of automotive manufacturing, used to produce everything from body panels to critical engine and safety components. The process is valued for its ability to create strong, lightweight parts that contribute to vehicle safety and fuel efficiency. Key applications include:

- Structural and Interior Components: Stamped parts are used for fenders, brackets, seat latches, and steering wheel components.

- Powertrain and Fuel Systems: Many parts within the engine, transmission, and fuel delivery systems, like fuel injector shields and bus-bars, are created through stamping.

- Electrical Systems: A modern vehicle contains numerous electrical systems that rely on stamped connectors, terminals, and sensor components.

The versatility and efficiency of metal stamping make it an essential fabrication process that fuels innovation and growth in these dynamic, high-volume industries.## Optimizing Production with Custom Metal Stamping Services

Beyond precision, custom metal stamping is a strategic choice for optimizing the entire production workflow, from initial design to final delivery. The process is engineered for efficiency, offering significant advantages in cost-effectiveness, scalability, and streamlined project management. For businesses looking to maximize their return on investment and bring products to market faster, metal stamping provides a robust and reliable manufacturing framework.

Cost-Effectiveness and Scalability

One of the most compelling arguments for custom metal stamping is its economic advantage, particularly for medium to high-volume production runs. While there is an initial investment in tooling, the long-term savings in per-part cost, material usage, and labor make it a highly cost-effective solution. This economic efficiency is paired with inherent scalability, allowing manufacturers to seamlessly ramp up production to meet market demands.

Reducing Costs and Maximizing Efficiency

Custom metal stamping is an inherently efficient process that significantly reduces manufacturing costs in several key ways. The automated nature of modern stamping can achieve incredibly high rates of production, with some presses operating at over 1,000 strokes per minute, which dramatically lowers the per-part cost. Once the custom die is created, the ongoing costs are primarily for raw material and machine maintenance, as the need for skilled labor is minimized.

Several strategies contribute to its cost-effectiveness:

- Material Waste Reduction: Custom metal stamping is designed to maximize the use of the raw metal coil or sheet. By optimizing the layout of parts on the metal strip, manufacturers can significantly reduce scrap, which is especially beneficial when working with expensive metals.

- Lower Tooling Costs for High Volumes: Although the upfront cost for a custom die can be significant, it is a one-time investment. That single die can then produce hundreds of thousands or even millions of identical parts. When this tooling cost is amortized over a large production run, the per-part tooling expense becomes minimal.

- Reduced Need for Secondary Operations: Modern stamping techniques, such as in-die tapping, coining, and assembly, can perform operations that would otherwise require separate, costly secondary processes. Designing the part with manufacturability in mind can eliminate the need for extra steps like deburring or drilling, further reducing costs and lead times.

Seamless Scaling for Production Demands

The scalability of metal stamping is a major advantage for businesses with fluctuating or growing production needs. The process is versatile enough to be cost-effective for both low-volume prototypes and massive production runs. This flexibility allows companies to adapt to the ebbs and flows of consumer demand without being penalized by high costs or long lead times.

- From Prototype to Mass Production: The metal stamping process is ideal for taking a product from the initial prototyping stage to full-scale production. Once a design is finalized and the tooling is proven, the same process can be used to manufacture parts in any volume. The modular nature of stamping equipment allows production capacity to be expanded efficiently by simply adding more presses or running more shifts.

- Handling High-Volume Runs: Metal stamping is built for speed and endurance. High-quality dies are engineered to withstand the consistent forces of high-speed stamping and can last for extended production runs without significant wear. This durability minimizes the need for tool replacements and reduces downtime, ensuring a smooth and uninterrupted supply of parts for high-demand products.

Streamlined Process from Design to Delivery

Leading custom metal stamping providers offer a truly integrated service that streamlines the entire journey from a customer's initial concept to the delivery of finished parts. This holistic approach, often managed under one roof, enhances collaboration, improves quality, and accelerates the time to market.

Collaborative Design and Prototyping

The most successful and cost-effective manufacturing outcomes begin long before any metal is cut. A collaborative approach known as Design for Manufacturability (DFM) is a strategic engineering practice that integrates manufacturing considerations into the very early stages of product design.

When designers and stamping engineers collaborate from the outset, they can optimize the part's design to reduce tooling costs, eliminate potential production issues, and ensure long-term reliability. This partnership allows for valuable insights into what is feasible, cost-effective, and efficient to produce. For example, simplifying a part's geometry or making small adjustments to avoid complex bends can significantly lower production time and expense without compromising function. The use of simulation and CAD software in this phase helps identify potential problems early, avoiding costly revisions during production. This collaborative DFM process is a win-win, leading to better parts, lower total costs, and a stronger partnership between the client and the manufacturer.

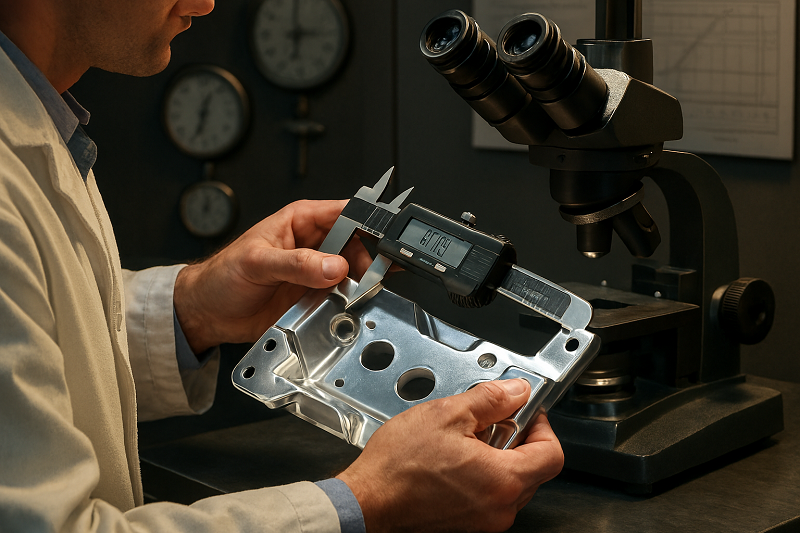

In-House Tooling and Quality Control

A key advantage of working with a premier metal stamping service is the presence of an in-house tooling department. Companies that design, build, and maintain their own tools and dies have complete control over a critical aspect of the manufacturing process. This vertical integration offers numerous benefits.

- Enhanced Quality and Control: When tooling is managed internally, toolmakers get constant feedback from the production team, leading to continuous improvement and flawless tool engineering over time. This ensures tools are built to exact specifications, which directly translates to higher and more consistent part quality.

- Reduced Lead Times and Costs: Keeping tool and die manufacturing in-house eliminates the delays, communication issues, and transportation costs associated with outsourcing to a third-party toolmaker. If a tool breaks down or needs maintenance, it can be addressed immediately on-site, minimizing production downtime.

- Integrated Quality Assurance: In-house quality control is the final piece of the streamlined process. From the moment a drawing is submitted to the final inspection of production parts, a dedicated quality team ensures every component meets critical dimensions and functional specifications. This constant oversight catches errors early, reduces waste, and guarantees that the final parts delivered to the customer are defect-free. This comprehensive control from start to finish is what sets a full-service stamping partner apart.## Custom Metal Stamping Services and the Future of Manufacturing

The manufacturing landscape is in a constant state of evolution, driven by the dual pressures of technological innovation and a growing global focus on environmental responsibility. Custom metal stamping is not just keeping pace with these changes; it is actively shaping the future of how precision parts are made. By embracing automation, smart manufacturing principles, and a strong commitment to sustainability, the metal stamping industry is positioning itself as a forward-thinking, efficient, and responsible solution for modern production challenges.

Embracing Automation and Smart Manufacturing

The integration of automation and smart manufacturing, often referred to as Industry 4.0, is transforming the metal stamping industry from a traditional practice into a high-tech, data-driven process. This evolution is leading to unprecedented levels of efficiency, precision, and flexibility.

Automation and Robotics: Automation is one of the most significant changes in modern metal stamping. Robotic systems are increasingly used to handle repetitive tasks such as loading raw materials, transferring parts between presses, and performing final inspections. This reduces the need for manual labor, which in turn minimizes human error, increases production speed, and ensures a higher level of consistency and precision in the final parts. Collaborative robots, or "cobots," are also being deployed to work alongside human operators, enhancing productivity by assisting with tasks like assembly and packaging.

Industry 4.0 and the Internet of Things (IoT): Smart manufacturing leverages the power of data by embedding sensors and IoT devices directly into stamping equipment. These sensors provide a constant stream of real-time data on machine performance, including parameters like temperature, pressure, and speed. This allows for adaptive manufacturing, where machine settings can be adjusted automatically to ensure consistent part quality. For example, sensors can measure the properties of incoming raw materials, and the a system can adjust cushion forces accordingly to prevent defects like cracks or wrinkles.

Predictive Maintenance and Digital Twins: Data analytics also enables predictive maintenance, where potential equipment failures are identified before they occur, minimizing unplanned downtime and improving overall uptime. Furthermore, the concept of a "digital twin"—a virtual replica of a physical stamping process—allows manufacturers to simulate and optimize production settings before manufacturing even begins. This helps to identify issues early, reduce scrap, and make data-driven decisions that enhance efficiency and quality.

The combination of these technologies is not just making metal stamping faster and more precise; it's making it a "smarter" process capable of self-optimization and continuous improvement.

Commitment to Sustainability

As global industries move toward a greener future, the metal stamping sector is making significant strides in reducing its environmental footprint. What was once seen as a resource-heavy process is now evolving into a more eco-friendly and sustainable manufacturing method through smarter processes and responsible practices.

The commitment to sustainability in metal stamping focuses on several key areas:

| Sustainability Practice | Description | Environmental Benefit |

|---|---|---|

| Material Efficiency | Advanced software and precision engineering optimize how parts are laid out on a metal sheet, a technique known as strip optimization. This practice maximizes the number of parts produced from a single coil and significantly reduces the amount of scrap metal. | Conserves natural resources, reduces landfill waste, and lowers raw material costs. |

| Recycling and Circularity | Scrap metal generated during production is collected, sorted, and reintroduced into the manufacturing cycle. This creates a closed-loop system where waste is minimized, and the demand for virgin raw materials is reduced. | Lowers energy consumption and greenhouse gas emissions associated with extracting and processing new raw materials. |

| Energy-Efficient Machinery | Modern stamping presses, especially servo-driven models, are far more energy-efficient than older equipment. They use power only when actively forming a part, which dramatically cuts down on idle energy consumption. Some facilities have also invested in on-site renewable energy sources like solar panels to further reduce their reliance on fossil fuels. | Reduces the overall carbon footprint of the manufacturing operation and lowers operational costs. |

| Eco-Friendly Lubricants | The use of bio-based, non-toxic, and low-residue lubricants is becoming more common. These environmentally friendly fluids reduce the need for harsh cleaning chemicals, are safer for workers, and are easier to dispose of or recycle. | Minimizes pollution and potential environmental hazards associated with traditional industrial chemicals. |

By prioritizing these green manufacturing practices, the metal stamping industry is demonstrating that high-volume, precision production can coexist with environmental responsibility. This commitment not only helps protect the planet but also offers a competitive advantage to businesses that appeal to an increasingly eco-conscious consumer base.

In conclusion, custom metal stamping services are indispensable for industries requiring high-precision, cost-effective, and scalable part production. The evolution of metal stamping, driven by technological advancements and a focus on quality, ensures that manufacturers can meet the most demanding specifications and deliver superior products to market. For businesses seeking a reliable partner for their custom metal stamping needs, SOMI Custom Parts offers comprehensive one-stop services, including OEM solutions, to transform innovative designs into reality.