Choosing Your Production Method: A Manufacturer's Guide to MJF vs. SLS 3D Printing for End-Use Parts

- Share

- Issue Time

- Jan 18,2026

Summary

Discover MJF vs SLS 3D printing for end-use parts: compare speed, strength, surface finish & cost. SOMI's guide helps manufacturers choose the right method for high-volume production.

MJF vs. SLS: The Ultimate Guide for Manufacturing Production Parts

In the world of industrial 3D printing, two powder bed fusion technologies stand out for producing strong, functional plastic parts: HP's Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS). Both are capable of creating complex geometries without the need for support structures, making them ideal for everything from advanced prototypes to end-use production runs. But while they seem similar on the surface, key differences in their processes have significant impacts on part quality, speed, cost, and overall performance. As a leading manufacturer of MJF parts, we're here to break down the nuances and show you why MJF is frequently the superior technology for modern manufacturing.

What is Powder Bed Fusion?

Before diving into the specifics of MJF vs. SLS, it's important to understand the family of technologies they belong to. Powder Bed Fusion (PBF) processes work by spreading a thin layer of fine polymer powder over a build platform. A thermal energy source then selectively fuses the powder particles according to a 3D model, layer by layer, until the object is complete. The unfused powder in the bed provides support, which is why these methods excel at creating intricate internal channels and complex shapes that are impossible with other manufacturing techniques.

How Do the Technologies Work?

While both are PBF processes, their methods of fusing the powder are fundamentally different. This core distinction is what drives the variations in part quality, speed, and cost.

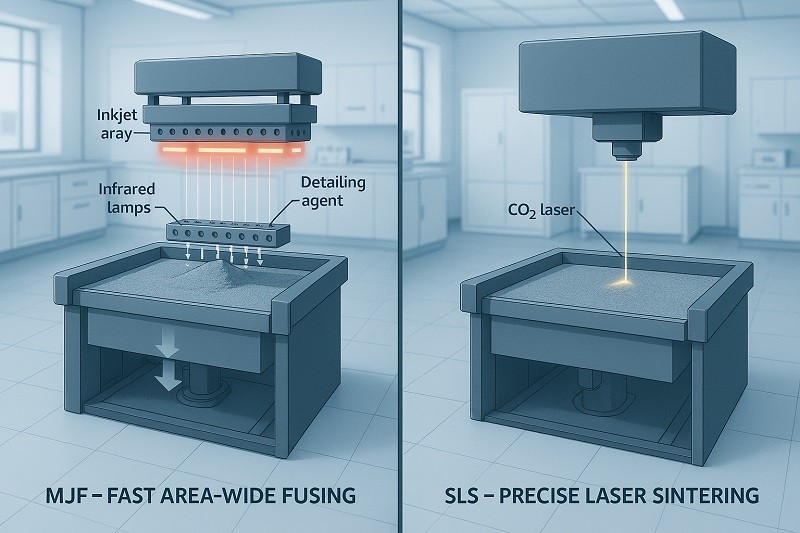

An Overview of Selective Laser Sintering (SLS)

SLS is a more mature technology that uses a high-powered CO2 laser to sinter (melt and fuse) the powder. The laser traces the cross-section of a part for each layer. After one layer is drawn, the build platform lowers, a new layer of powder is spread, and the process repeats. This point-by-point laser scanning can be time-consuming and creates parts that can have anisotropic properties, meaning their strength differs depending on their orientation in the printer.

An Overview of Multi Jet Fusion (MJF)

Developed by HP, MJF uses a different, more production-oriented approach. An inkjet-style print head sweeps across the powder bed, depositing two chemical agents: a fusing agent where the part should be solid and a detailing agent around the edges. An infrared heating lamp then passes over the entire bed, and the powder treated with the fusing agent absorbs the heat and melts instantly. The detailing agent helps create sharp edges and a smoother surface. This layer-by-layer, area-wide process is significantly faster than the single-point laser of SLS.

Mechanical Properties: Strength and Durability

For functional parts, mechanical performance is paramount. This is an area where MJF truly shines. MJF parts are known for their isotropic properties, meaning they have nearly uniform strength and durability in all directions (X, Y, and Z axes). This is due to the more consistent melting process across each layer. SLS parts, conversely, are often anisotropic. The bond between layers (Z-axis) is typically weaker than the strength within a single layer (X-Y plane), which is a critical design consideration for parts under stress.

When comparing the standard material for both, Polyamide 12 (PA12), MJF parts generally exhibit superior tensile strength and flexibility. For example, both technologies offer a tensile strength of around 48 MPa, but MJF parts often show greater elongation at break, making them more durable and less brittle.

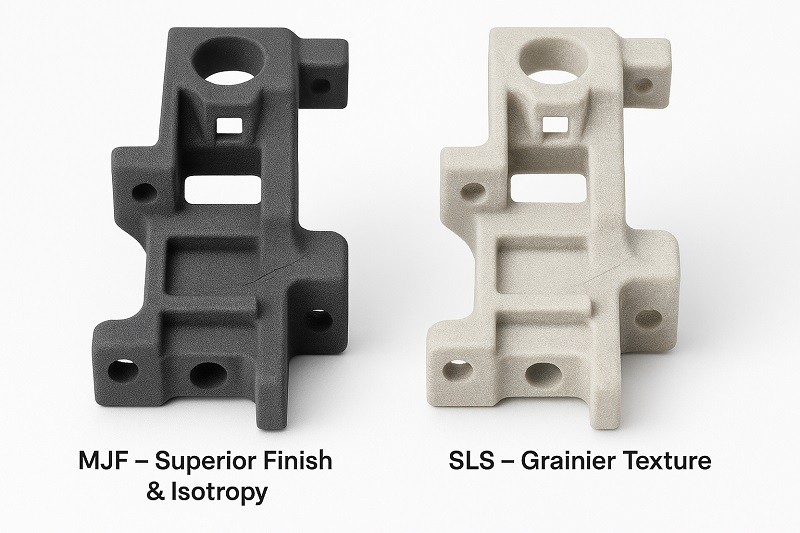

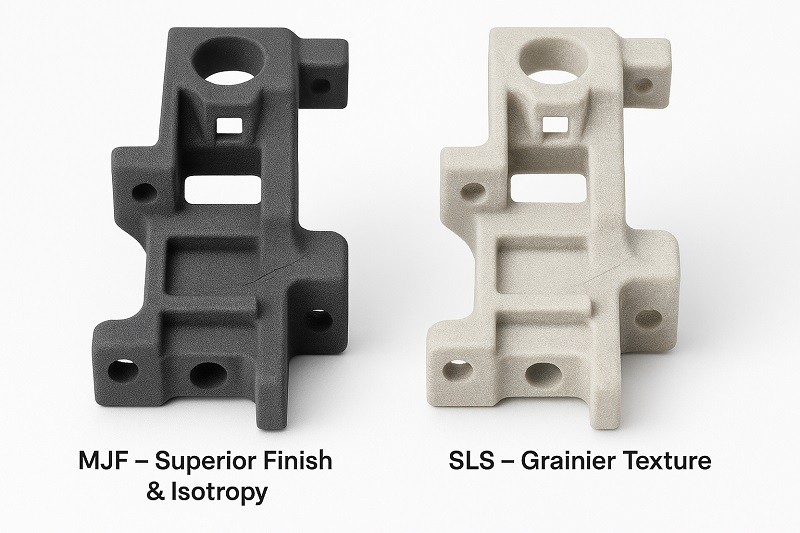

Surface Finish and Aesthetic Quality

MJF often produces a smoother, more consistent surface finish straight out of the printer. The use of a detailing agent allows for crisper edges and finer feature resolution, typically around 0.5 mm. The resulting parts are usually dark grey and have a semi-gloss, slightly textured feel that is often acceptable for end-use applications without any post-processing.

SLS parts, on the other hand, tend to have a rougher, more porous or grainy texture. The surface reflects the size of the powder particles and can feel slightly fuzzy. While various post-processing methods like tumbling or vapor smoothing can improve this, MJF provides a superior out-of-the-box finish.

Accuracy and Dimensional Precision

Both technologies offer high dimensional accuracy, but MJF often has a slight edge due to its printing process. MJF printheads can deposit the fusing agent with a resolution of 1200 DPI, leading to incredibly fine detail and sharp features. SLS relies on a laser spot size, which is typically larger (around 0.3-0.4 mm), limiting the smallest features it can accurately produce. For parts requiring intricate details, small holes, or sharp text, MJF is the more reliable choice.

Speed, a Decisive Factor in Production

For batch production and getting parts to market quickly, speed is everything. MJF is inherently faster than SLS. Instead of a laser tracing every detail, MJF fuses an entire layer at once. Furthermore, MJF’s workflow is optimized for production. HP offers dedicated post-processing stations that significantly accelerate the cooling time. In an SLS process, the entire build bin must cool down slowly inside the printer to avoid part warping, creating a bottleneck. With MJF, the build unit can be moved to a separate station to cool, freeing the printer to start the next job immediately.

Material Options: Versatility vs. Optimization

Historically, SLS has had the advantage of a broader material library, including various nylons (PA11, PA12), flexible TPU, and filled composites like glass-filled or aluminum-filled nylon. However, MJF's material catalog is rapidly expanding. While PA12 remains the workhorse material, options now include flexible TPU and durable Polypropylene (PP), a material SLS struggles with. MJF technology is designed as an open platform, which encourages rapid development of new materials.

The Economic Advantage: Cost Per Part

For one-off prototypes, the cost between MJF and SLS can be comparable. However, when it comes to series production, MJF is almost always more cost-effective. There are several reasons for this:

- Faster Print Speed: Less printer time directly translates to lower cost.

- Higher Powder Recyclability: MJF boasts a powder refresh rate where up to 80-85% of the unused powder can be recycled and mixed with new powder for the next build. SLS typically has a much lower recyclability rate (around 50%), leading to more material waste and higher costs.

- Nesting Density: The faster and more consistent heating process allows for denser packing of parts within the build volume, increasing throughput and lowering the cost per part. Studies show that for medium to large production runs, MJF can be 15-30% more affordable than SLS.

Comparison Table: MJF vs. SLS

| Feature | Multi Jet Fusion (MJF) | Selective Laser Sintering (SLS) |

|---|---|---|

| Principle | Fusing agent and infrared heat | High-power laser sintering |

| Mechanical Strength | Isotropic (uniform strength in all directions) | Anisotropic (weaker in Z-axis) |

| Surface Finish | Smoother, finer detail (dark grey) | Grainy, slightly rough (typically white) |

| Accuracy | Excellent, with high resolution (1200 DPI) | Very good, but limited by laser spot size |

| Printing Speed | Faster, especially for batch production | Slower, due to point-by-point laser scanning |

| Cost | More cost-effective for medium to high volumes | More expensive for production runs due to speed and waste |

| Powder Refresh Rate | High (approx. 80-85% reusable) | Lower (approx. 50% reusable) |

| Main Materials | PA12, PA11, TPU, Polypropylene | PA12, PA11, TPU, Filled Composites (Glass/Carbon) |

Why Choose an MJF Parts Manufacturer?

Choosing MJF means prioritizing speed, cost-efficiency, and superior, consistent part quality. It is the technology built for the factory floor, designed to scale from prototyping to full-scale production seamlessly. As a manufacturer specializing in MJF, we have harnessed this technology to deliver production-grade parts for the most demanding applications in aerospace, automotive, medical, and consumer goods. Our expertise ensures that you can leverage the full potential of MJF for your projects, benefiting from strong, detailed, and affordable components with rapid turnaround times.

Ready to see the MJF difference for yourself? Upload your 3D model now for an instant quote.