Beyond Off-the-Shelf: Why Custom Connectors & Fasteners Are Driving the Future of Electronics

- Share

- Issue Time

- Jan 2,2026

Summary

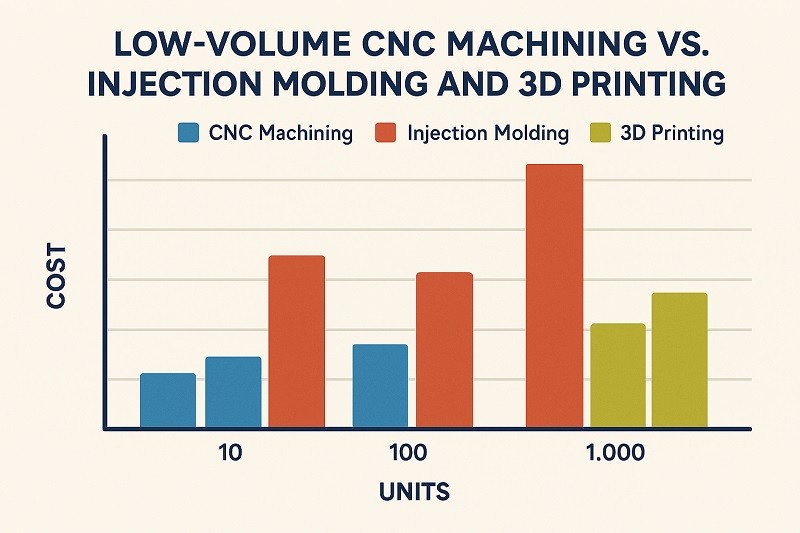

Low-volume CNC machining offers agile, on-demand production for 10-10,000 parts, bridging prototyping and mass manufacturing with cost efficiency, flexibility, and rapid turnaround.

The Unseen Revolution: Miniaturization's Impact on Component Design

The world of electronics is relentlessly shrinking. From the smartphone in your pocket to the advanced guidance systems in aerospace, the mandate is clear: make it smaller, lighter, and more powerful. This trend, known as miniaturization, has been the primary driver of technological innovation for decades. As devices become more compact and feature-rich, however, design engineers are hitting a wall with traditional, off-the-shelf components. Standard connectors and fasteners, once perfectly adequate, are now often too bulky, too generic, or simply not robust enough for the demands of modern high-density designs. This challenge has given rise to an essential and rapidly growing field: custom-designed connectors and fasteners.

The Limitations of Standard, Off-the-Shelf Components

For years, designers relied on a vast catalog of standard parts. This approach offered convenience and low costs due to mass production. However, in the context of highly integrated and miniaturized electronics, this one-size-fits-all model reveals its flaws. Standard connectors can dictate the product's final form factor, forcing engineers to design around the component rather than for the ideal user experience. They may not offer the specific pin configurations, current ratings, or signal integrity needed for high-speed data transmission in a tight space. Similarly, standard fasteners might not provide the required clamping force, vibration resistance, or material properties for a unique application, compromising the device's long-term reliability.

What Are Custom Connectors and Fasteners?

Custom connectors and fasteners are components engineered specifically for a single application. Instead of choosing from a pre-existing catalog, designers work with specialized manufacturers to create a solution tailored to their exact needs. This can range from a simple modification of an existing design—like changing the length of a pin or the material of a housing—to a completely new, clean-sheet design created from the ground up. This bespoke approach ensures that every aspect of the component, from its physical footprint and shape to its electrical and mechanical performance, is perfectly optimized for the device it serves.

Key Drivers for Custom-Engineered Solutions

The shift toward customization is not arbitrary; it is driven by clear technological and market demands. As devices continue to evolve, custom components are becoming a necessity for achieving cutting-edge performance and design.

Extreme Space Optimization

In wearable technology, medical implants, and portable electronics, every millimeter counts. Custom connectors can be designed to fit unconventional shapes, integrate into the product housing, and achieve incredibly low profiles and high pin densities that are impossible with standard parts. Custom fasteners, such as micro-screws with ultra-thin heads, allow for secure assembly in spaces previously considered unusable.

Enhanced Electrical Performance

High-speed data transmission and high-power applications introduce challenges like signal loss, crosstalk, and thermal buildup. Custom connectors address these issues by allowing for optimized contact design, specific material selection for improved conductivity, and integrated shielding. This ensures superior signal integrity and efficient thermal management, even in the most densely packed PCBs.

Reliability in Harsh Environments

From aerospace and defense systems that must withstand extreme vibration and temperature shifts to medical devices that require sterilization and biocompatibility, standard components often fall short. Customization allows for the selection of specialized materials, platings, and locking mechanisms to ensure the connector or fastener performs reliably under the most demanding conditions.

Unique Form Factors and Ergonomics

Product differentiation often comes down to design. Custom connectors can be shaped and colored to blend seamlessly with a product’s aesthetic or designed for specific ergonomic requirements, such as in surgical tools or ruggedized field equipment where ease of use is critical.

The Custom Component Design & Manufacturing Process

Creating a custom connector or fastener is a collaborative, multi-stage process that turns a unique challenge into a tangible solution.

- Consultation and Concept: Engineers collaborate with the manufacturer to define the mechanical, electrical, and environmental requirements.

- Design and Simulation: Using advanced CAD and simulation software, a virtual model is created. This allows for analysis of factors like stress, thermal performance, and signal integrity before any physical parts are made.

- Prototyping: Rapid prototyping techniques, such as 3D printing and precision machining, are used to create functional samples for testing and validation.

- Tooling and Production: Once the design is finalized, production tooling is created, and the components are manufactured at scale using processes like injection molding and precision stamping.

- Quality Assurance: Throughout the process, rigorous testing ensures that every component meets the exact specifications and quality standards required.

Case Study: Custom Solutions in Medical Devices

Consider a next-generation wearable patient monitor. It needs to be small, lightweight, and water-resistant, while accurately transmitting multiple biometric data streams. A standard connector would be too bulky and might not provide a secure, moisture-proof seal. A custom solution, however, can be designed as a low-profile, circular connector with a specific number of pins for both power and data, a specialized locking mechanism for secure attachment, and materials that are both biocompatible and resistant to cleaning agents. This level of optimization is only possible through custom design.

Case Study: Aerospace and Defense Applications

In a military drone, components must be both lightweight and incredibly rugged. A custom high-density connector can consolidate power, signal, and RF connections into a single, compact housing, significantly reducing weight and potential points of failure. The connector can be built with specialized aluminum alloys and high-performance polymers to withstand intense vibration and extreme temperatures. Similarly, custom fasteners with self-locking features ensure that critical components remain secure during high-G maneuvers.

It’s Not Just Connectors: The Critical Role of Fasteners

While connectors get much of the attention, the fasteners that hold an assembly together are equally critical in high-density electronics. As PCBs become thinner and components more tightly packed, standard screws can cause stress fractures or take up too much space. Custom micro fasteners are designed to solve these problems. They can be manufactured with specific thread profiles for different materials (like plastics and soft metals), ultra-low-profile heads to maximize internal clearance, and specialized drive types for automated assembly.

Standard vs. Custom Fasteners: A Comparison

| Feature | Standard Fasteners | Custom Fasteners |

|---|---|---|

| Design | Generic, one-size-fits-many | Application-specific design |

| Material | General-purpose steel, stainless steel | Specialized alloys, non-magnetic materials, plastics |

| Head Profile | Standard heights and diameters | Ultra-low-profile, custom shapes for branding |

| Performance | Adequate for general use | Optimized for clamping force, vibration resistance |

| Space | Can be bulky and limit design | Maximizes internal clearance, enables miniaturization |

Overcoming the Challenges of Miniaturization

Designing at the micro-level presents unique challenges. Thinner materials can reduce mechanical strength, and tight spacing can increase the risk of electrical interference. However, these are precisely the problems that custom design solves. By leveraging advanced simulation, selecting superior materials, and optimizing the geometry of every feature, custom component manufacturers can mitigate these risks and deliver parts that are both miniature and robust.

The Future is Custom

As technology continues to advance, the gap between what standard components can offer and what innovative products require will only widen. Miniaturization, high-speed data, and the need for greater reliability are pushing engineering to its limits. Custom connectors and fasteners are no longer a niche solution but a fundamental enabler of future technology. By partnering with an experienced manufacturer, designers can break free from the constraints of off-the-shelf parts and build the smaller, faster, and more reliable products of tomorrow.