Aluminum Enclosure CNC Machining Services for High-Performance Lightweight Aerospace Components

- Share

- Issue Time

- Dec 10,2025

Summary

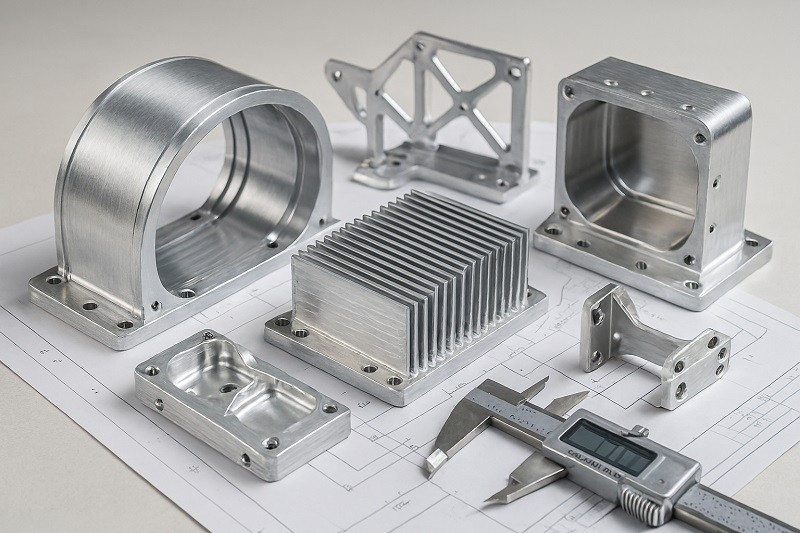

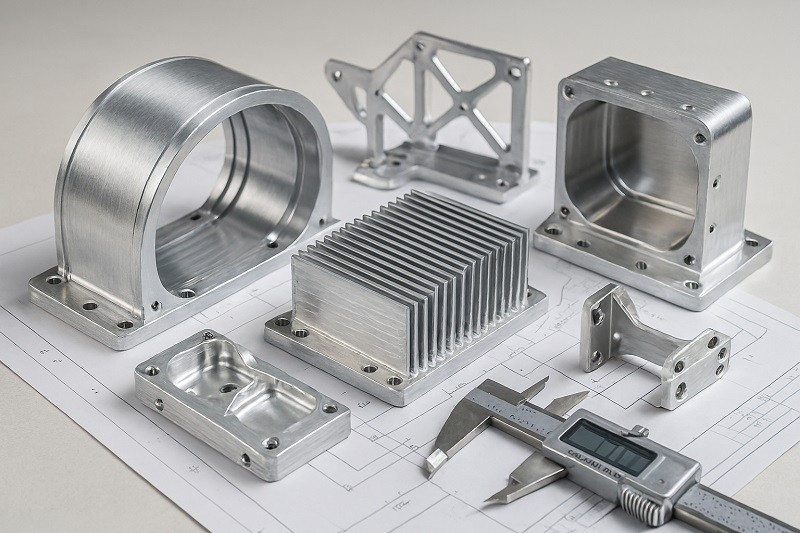

In the aerospace industry, where precision and reliability are non-negotiable, Aluminum Enclosure CNC (Computer Numerical Control) machining services are vital for creating high-performance, lightweight, and durable components. This advanced manufacturing process, using computer-controlled tools, ensures unparalleled accuracy and repeatability, crucial for parts that must endure extreme conditions such as varying temperatures, vibrations, and aerodynamic stresses.

In the demanding aerospace industry, precision and reliability aren't just buzzwords—they are fundamental requirements for safety and performance. Every component, from the smallest bracket to the most complex engine part, must meet exacting standards to operate flawlessly in extreme conditions. This is where aluminum enclosure CNC machining services emerge as a cornerstone, transforming raw materials into high-performance, lightweight components that defy gravity and ensure mission success.

CNC (Computer Numerical Control) machining offers unparalleled accuracy and repeatability, making it an indispensable technology for producing intricate designs with tight tolerances. This advanced manufacturing process allows for the creation of crucial parts with precision that can be finer than a human hair, directly contributing to fuel efficiency, enhanced performance, and the overall operational integrity of both commercial and military aircraft, as well as space exploration vehicles. This article will explore how a professional CNC Machining Service is shaping the future of aerospace by blending cutting-edge technology with practical, high-performance solutions.

The Indispensable Role of Aluminum Enclosure CNC Machining Services in Aerospace Manufacturing

The aerospace sector's relentless pursuit of innovation hinges on manufacturing capabilities that can keep pace with increasingly complex designs and material requirements. Aluminum enclosure CNC machining services have become a critical pillar of modern aerospace manufacturing, providing the foundation for building next-generation aircraft and spacecraft. This technology is not merely a production method; it is an enabling force that allows engineers to turn ambitious concepts into tangible, flight-worthy hardware. Its role extends beyond simple part creation, influencing everything from aerodynamic efficiency and structural integrity to the overall economic viability of a project.

Achieving Unmatched Precision and Durability

In the world of aerospace, precision is not a suggestion; it is a mandate. Components must endure extreme temperatures, vibrations, and aerodynamic loads, where even the smallest geometric error can lead to performance degradation or catastrophic failure. CNC machining answers this need by creating parts with exceptionally tight tolerances, sometimes as small as 0.001 inches, ensuring every piece fits and functions exactly as designed. This level of accuracy is critical for everything from engine components that manage airflow to structural elements that maintain an aircraft's integrity.

Furthermore, the durability of a component is directly linked to how it is manufactured. Advanced CNC machining preserves the material's microstructure by controlling factors like heat buildup and tool paths, which prevents the formation of microcracks that could lead to fatigue failure over time. By starting with a solid block of high-grade aluminum and machining it into a final shape, the process creates a monolithic part with superior structural integrity compared to assemblies of multiple, smaller pieces. This integral machining approach improves fatigue performance and overall longevity, which are crucial for parts subjected to the cyclical stresses of flight.

Enabling Lightweight and Robust Designs

Weight is a primary adversary in aerospace design; every kilogram saved can translate into thousands of dollars in fuel savings over an aircraft's operational lifespan. Aluminum is an ideal material for this challenge, offering an excellent strength-to-weight ratio that allows for the creation of durable components without adding unnecessary mass. While materials like steel are stronger in absolute terms, aluminum is approximately one-third the density, giving it a superior strength-to-weight ratio that is critical for applications in aviation and spaceflight.

CNC machining is uniquely suited to maximize this lightweighting potential. It allows engineers to design parts with complex, topologically optimized geometries, such as thin walls, deep pockets, and honeycomb-like internal structures. This subtractive process carves away any material that doesn't contribute to the part's structural integrity, resulting in a component that is as light as possible while still meeting all strength and performance requirements. For example, large structural components like wing ribs and fuselage frames can be machined from a single aluminum billet, creating a lightweight yet rigid part with geometries that would be impossible to achieve with traditional methods.

Cost-Effectiveness and Efficiency Through Advanced Automation

While the initial investment in advanced CNC machinery is significant, the long-term economic benefits for aerospace manufacturing are substantial. Automation is the key driver of this cost-effectiveness. Once a design is programmed, CNC machines can operate continuously, 24/7, with minimal human intervention. This drastically reduces labor costs compared to manual machining and increases overall output. The ability to automate repetitive tasks not only accelerates production but also frees up skilled technicians to focus on more complex, value-added activities like quality control and process optimization.

Furthermore, the precision of CNC machining directly translates to greater material efficiency. Aerospace-grade materials like titanium and high-strength aluminum alloys are expensive, and waste can significantly inflate project costs. CNC machining optimizes material usage by precisely carving parts from raw stock, minimizing scrap. This efficiency reduces material waste by up to 90% in some cases compared to traditional methods. The high repeatability of the process also means fewer defects and rejected parts, which further reduces material and production costs while ensuring consistent quality across every component.

| Feature | CNC Machining | Traditional Manufacturing |

|---|---|---|

| Labor Requirement | Low (Primarily for setup and oversight) | High (Requires skilled manual operators) |

| Consistency | High and repeatable | Varies with operator skill |

| Material Waste | Minimized through optimized toolpaths | Higher due to manual control |

| Production Speed | Fast, with 24/7 operation possible | Slower, limited by work shifts and fatigue |

| Complexity of Parts | High (Complex geometries easily produced) | Limited (Complex shapes are difficult and costly) |

Materials of Choice for High-Performance Aluminum Enclosure CNC Machining Services

The performance of an aerospace component is intrinsically linked to the material from which it is made. Selecting the right material is a critical decision that balances requirements for strength, weight, temperature resistance, corrosion resistance, and cost. While aluminum alloys are a mainstay, the diverse demands of aerospace applications necessitate a broad portfolio of machinable materials, including titanium, superalloys, and even advanced engineering plastics.

The Versatility of Aluminum Alloys

Aluminum alloys are foundational materials in the aerospace industry, prized for an exceptional combination of low density, high strength, good machinability, and corrosion resistance. An estimated 80% of a modern aircraft's structure is made from these alloys. Different series offer distinct advantages, allowing engineers to select the optimal grade for a specific application.

Two of the most prominent aerospace-grade aluminum alloys are 6061 and 7075:

- Aluminum 6061: Often called a "jack of all trades," 6061 offers a great balance of properties. It has good strength, excellent corrosion resistance, and high workability, making it easy to machine and weld. Its versatility makes it a popular choice for structural components, aircraft frames, and hydraulic systems.

- Aluminum 7075: This alloy is known for its exceptional strength, which is comparable to many types of steel. Its strength-to-weight ratio is one of the highest among aluminum alloys. The primary alloying element is zinc, which contributes to its high tensile and yield strength. This makes 7075 the go-to material for high-stress, mission-critical components like wing spars, fuselage bulkheads, and landing gear parts. However, this strength comes at the cost of lower corrosion resistance and more challenging machinability compared to 6061.

The choice between these alloys depends on the specific demands of the component. The table below summarizes their key differences.

| Property | Aluminum 6061 | Aluminum 7075 |

|---|---|---|

| Primary Alloying Elements | Magnesium, Silicon | Zinc, Magnesium, Copper |

| Strength | Good | Excellent (nearly twice the tensile strength of 6061) |

| Corrosion Resistance | Excellent | Fair (often requires protective coating) |

| Machinability | Excellent | Fair (more difficult to machine) |

| Weldability | Good | Poor (generally considered not weldable) |

| Common Applications | General structural parts, electronic enclosures, piping, frames. | High-stress structural parts, gears, missile components. |

Beyond Aluminum: Titanium and Superalloys

For applications where temperatures and mechanical stresses exceed the capabilities of aluminum, aerospace engineers turn to titanium alloys and nickel-based superalloys.

Titanium Alloys: Titanium is prized in aerospace for its high strength-to-weight ratio (superior to aluminum), excellent corrosion resistance, and remarkable performance at elevated temperatures. The most common titanium alloy, Ti-6Al-4V (Grade 5), is used extensively for structural airframe components, landing gear, and engine parts like fan blades and discs. However, titanium is notoriously difficult to machine. Its low thermal conductivity causes heat to build up at the cutting tool, leading to rapid tool wear and potential damage to the workpiece. Successful CNC machining of titanium requires specialized tooling, rigid machine setups, high-pressure coolant, and carefully optimized cutting strategies to manage heat and preserve the material's integrity.

Superalloys: Superalloys are a class of materials, typically nickel-based, cobalt-based, or iron-based, designed to operate in extreme environments of high temperature, high pressure, and corrosive atmospheres. These are the materials of choice for the hottest sections of jet and rocket engines. Nickel-based superalloys like Inconel® are widely used for components such as turbine blades, combustion chambers, and exhaust systems. Inconel, for example, forms a stable, passivating oxide layer at high temperatures, which protects it from heat and oxidation. This allows it to retain exceptional mechanical strength in environments where aluminum and even steel would fail. Machining superalloys presents even greater challenges than titanium due to their extreme hardness and high work-hardening rates.

Exploring Engineering Plastics and Composites

The aerospace industry's material palette is not limited to metals. Advanced engineering plastics and composite materials are increasingly used for their unique properties, and CNC machining is a key technology for shaping them into functional components.

Engineering Plastics (PEEK and ULTEM): High-performance thermoplastics like PEEK (Polyether Ether Ketone) and ULTEM (Polyetherimide) are becoming vital for specific aerospace applications. These materials offer an impressive combination of light weight, high strength, chemical resistance, and inherent flame retardancy. ULTEM, for example, is widely used for interior aircraft components like personal service units, ventilation systems, and door handles because it meets stringent FAA regulations for flammability, smoke, and toxicity (FST). PEEK is often used as a metal replacement for parts like brackets, clamps, bushings, and seals, where its excellent strength-to-weight ratio and wear resistance can improve fuel efficiency and reduce maintenance. CNC machining is ideal for creating these parts with high precision and excellent surface finishes.

Composites (Carbon Fiber): Carbon Fiber Reinforced Polymers (CFRPs) offer an unparalleled strength-to-weight ratio, making them a material of choice for modern airframes, including the fuselage and wings of aircraft like the Boeing 787 and Airbus A350. However, machining composites like carbon fiber presents a unique set of challenges. The material is highly abrasive, which leads to rapid tool wear. The layered structure makes it prone to defects like delamination (separation of layers), fiber pull-out, and fuzzing if not machined correctly. These issues can compromise the structural integrity of the part. Overcoming these challenges requires specialized diamond-coated cutting tools, high-speed machines, optimized toolpaths, and effective dust extraction systems to manage the hazardous carbon dust produced during machining.

Advanced Techniques in Aluminum Enclosure CNC Machining Services for Complex Geometries

Modern aerospace design is characterized by its complexity. Engineers are constantly developing more integrated and aerodynamically efficient components that push the limits of traditional manufacturing. To meet these demands, CNC machining has evolved beyond simple 3-axis operations, incorporating advanced techniques that enable the production of highly intricate parts with greater speed and precision than ever before.

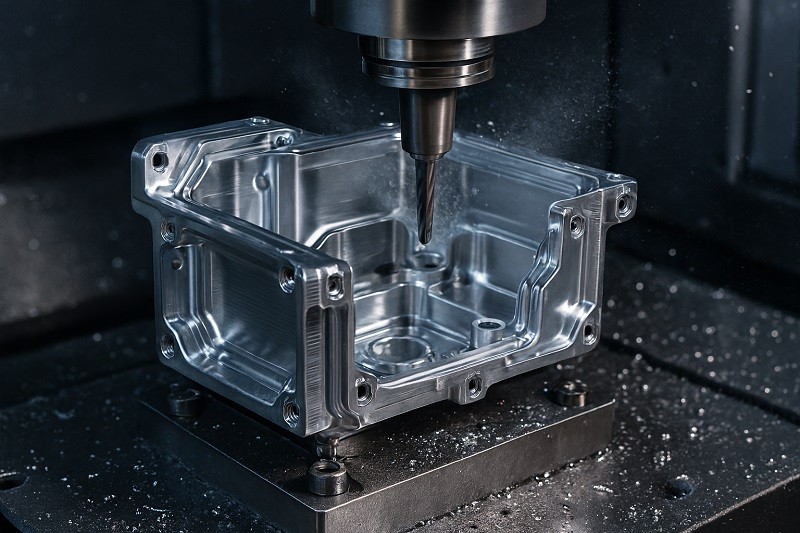

Mastering Multi-Axis and High-Speed Machining

Traditional 3-axis CNC machines operate on the X, Y, and Z linear axes, which is sufficient for simpler parts. However, aerospace components frequently feature complex curves, undercuts, and compound angles that are impossible to create without re-fixturing the part multiple times. Each new setup introduces the potential for alignment errors, increasing production time and reducing accuracy.

This is where multi-axis machining, particularly 5-axis CNC machining, becomes a game-changer. By adding two rotational axes (A and B) to the standard three linear axes, a 5-axis machine can move the cutting tool or the workpiece in a way that allows the tool to approach the part from virtually any angle. This provides several key benefits:

- Single-Setup Machining: Complex parts like turbine blades, impellers, or multi-faceted structural components can be machined in a single setup. This dramatically reduces production time and eliminates the cumulative errors associated with multiple setups, resulting in higher precision.

- Shorter, More Rigid Tools: The ability to tilt the tool or workpiece allows for the use of shorter, more rigid cutting tools. This minimizes tool vibration and deflection, leading to a superior surface finish and greater dimensional accuracy.

- Improved Tool Life: 5-axis toolpaths can maintain an optimal cutting position and a constant chip load, which reduces wear and tear on the cutting tool and extends its life.

In parallel, High-Speed Machining (HSM) is another critical technique, especially for aluminum. HSM uses very high spindle speeds and feed rates but with a lighter depth of cut. This strategy is surprisingly effective for aluminum, as it allows chips to be evacuated quickly, carrying heat away from the workpiece and preventing thermal distortion. The benefits of HSM for aerospace aluminum include faster material removal rates, reduced cycle times, and an excellent surface finish.

This is why advanced Axis CNC Milling is essential for meeting modern aerospace demands, as it combines the geometric freedom of multi-axis movement with the speed and quality of HSM.

Integrating Additive Manufacturing and Smart Technologies

The future of aerospace manufacturing lies in the intelligent integration of different production methods and the adoption of digital technologies that create a more connected and efficient workflow.

Hybrid Additive and Subtractive Manufacturing: This innovative approach combines the best of both worlds: the geometric freedom of additive manufacturing (3D printing) and the precision of subtractive manufacturing (CNC machining). The process often starts by 3D printing a "near-net-shape" part, which is a rough version of the final component that is very close to its final dimensions. This method is highly efficient, as it only uses the material needed to build the part, drastically reducing waste—a significant cost-saver when working with expensive aerospace alloys. The near-net-shape part is then transferred to a CNC machine for finishing. The CNC machine removes a small amount of material to achieve the tight tolerances, critical features, and smooth surface finishes required for aerospace applications. This hybrid model is particularly useful for creating lightweight components with complex internal structures, like conformal cooling channels, that would be impossible to produce with either method alone.

Digital Twins and the Industrial Internet of Things (IIoT): Smart manufacturing, or Industry 4.0, is transforming the factory floor, and CNC machining is at the heart of this revolution.

- Digital Twin: A digital twin is a dynamic, virtual replica of a physical CNC machine or even an entire production line. This virtual model is continuously updated with real-time data from sensors on the physical machine, allowing engineers to simulate machining processes, test toolpaths, and predict outcomes without touching a real workpiece. For aerospace, this means new designs can be validated virtually, potential collisions can be avoided, and processes can be optimized for efficiency and quality before production even begins, significantly reducing errors and development time.

- IoT Sensors: The Industrial Internet of Things (IIoT) involves embedding smart sensors into CNC machines to monitor a wide range of parameters in real time, such as spindle vibration, temperature, tool wear, and coolant flow. This data provides invaluable insights. For instance, predictive maintenance algorithms can analyze vibration data to forecast a potential bearing failure and schedule maintenance before a costly breakdown occurs. This technology also enhances quality control by providing full traceability, linking a finished part back to the exact machine conditions under which it was made—a critical requirement for aerospace compliance.

Ensuring Uncompromising Quality and Compliance in Aluminum Enclosure CNC Machining Services

In an industry where safety and reliability are paramount, quality is not an afterthought—it is an integral part of the manufacturing process from start to finish. For aluminum enclosure CNC machining services in the aerospace sector, this means adhering to a multi-layered system of stringent quality control protocols, navigating a complex web of certifications and standards, and applying specialized surface treatments to ensure components can withstand the harshest operating conditions.

Stringent Quality Control and Inspection Protocols

A robust quality control system is foundational to aerospace manufacturing. This process begins with raw material inspection to verify that all materials meet the specified grade and properties and is followed by a multi-stage inspection protocol.

- First Article Inspection (FAI): Before full-scale production begins, the very first part machined is subjected to an exhaustive inspection to confirm it meets all design specifications. This critical step ensures the CNC program and setup are correct, preventing the mass production of faulty parts.

- In-Process Monitoring: Quality is not just checked at the end; it is monitored throughout the machining process. On-machine probing systems and real-time data from IoT sensors help detect any deviations from the plan as they happen, allowing for immediate corrections.

- Final Inspection: Once a batch of components is complete, a comprehensive final inspection is performed. This is where advanced metrology equipment plays a crucial role.

Coordinate Measuring Machines (CMMs) are the gold standard for final inspection. These devices use a highly sensitive probe to take precise measurements of a part's geometry across three dimensions (X, Y, and Z). The collected data points create a detailed 3D map of the component, which is then compared against the original CAD model to verify that every dimension, angle, and contour is within the specified tolerance, sometimes as tight as a few microns.

Non-Destructive Testing (NDT) is also essential for uncovering flaws that are not visible to the naked eye. These methods inspect a part's integrity without causing any damage. Common NDT methods used in aerospace include:

- Ultrasonic Testing (UT): High-frequency sound waves are sent through the material to detect subsurface defects like cracks or voids.

- Fluorescent Penetrant Inspection (FPI): A fluorescent dye is applied to the surface, which seeps into any surface-breaking cracks. Under a black light, the dye reveals flaws that would otherwise be invisible.

- Radiography Testing (RT): Similar to a medical X-ray, this method is used to identify internal voids and defects within the material's structure.

Navigating Aerospace Certifications and Standards

Operating in the aerospace supply chain requires adherence to a strict set of internationally recognized standards and regulations. These certifications are not optional; they are a prerequisite for any machine shop aiming to produce flight-critical components.

ISO 9001: This is the international standard for a Quality Management System (QMS). While not specific to aerospace, ISO 9001 provides the foundational framework for ensuring process consistency, customer satisfaction, and continuous improvement. It demonstrates that a manufacturer has a systematic approach to quality that is documented, audited, and maintained.

AS9100: This is the gold standard for quality management in the aerospace, space, and defense industries. AS9100 incorporates all the requirements of ISO 9001 but adds nearly 100 additional clauses that are specific to aerospace. These additions place a heavy emphasis on critical areas such as risk management, product safety, configuration management, and material traceability. Earning AS9100 certification signifies that a CNC machining provider adheres to the rigorous quality and safety expectations of clients like Boeing, Airbus, and NASA.

ITAR (International Traffic in Arms Regulations): This is a United States regulatory regime to restrict and control the export of defense and military-related technologies to safeguard U.S. national security. Any manufacturer that handles components or technical data listed on the U.S. Munitions List (USML) must be ITAR registered and compliant. This involves implementing strict security protocols to control access to facilities and sensitive data, ensuring that only authorized U.S. persons can view or handle defense-related projects. For CNC machining shops, this is a non-negotiable requirement for participating in military and defense contracts.

Compliance with these standards is verified through rigorous audits by third-party registrars. Maintaining these certifications requires a deep-seated commitment to quality and a culture of continuous improvement that permeates every aspect of the manufacturing process.

Tailored Surface Treatments for Enhanced Performance

The manufacturing process doesn't end when the CNC machine stops. For aerospace components, specialized surface treatments are often required to enhance their properties and ensure they can perform reliably in extreme environments. These treatments are not merely cosmetic; they provide critical protection against corrosion, wear, and fatigue.

Anodizing: This is an electrochemical process used almost exclusively on aluminum parts. It involves immersing the component in an acid electrolyte bath and passing an electrical current through it. This converts the surface of the aluminum into a durable, corrosion-resistant, and non-conductive layer of aluminum oxide. The thickness and density of this layer can be precisely controlled. For aerospace, there are two primary types:

- Type II (Sulfuric Acid Anodizing): Creates a protective layer that offers good corrosion resistance and can be dyed in various colors.

- Type III (Hardcoat Anodizing): Produces a much thicker and denser oxide layer, providing superior wear and abrasion resistance in addition to corrosion protection. This is ideal for components subjected to extreme wear or harsh environments.

Chromate Conversion Coating (Chem Film/Alodine): This chemical process creates a thin, protective film on the surface of aluminum. Unlike anodizing, a chromate conversion coating is electrically conductive, which is a critical requirement for parts that need to be grounded or provide electrical continuity to prevent static discharge. The primary benefits of this treatment are excellent corrosion resistance and providing a superior primer for subsequent painting. It minimally affects the dimensions of the part, making it suitable for components with very tight tolerances.

Passivation: Passivation is a chemical treatment primarily used on corrosion-resistant steels, but it is also relevant to aerospace components to ensure maximum cleanliness and corrosion resistance. The process removes free iron and other contaminants left on the surface from machining operations. These contaminants can act as initiation sites for corrosion. Passivation restores a uniform, passive oxide layer, which is what gives stainless materials their inherent corrosion resistance. This treatment is critical for ensuring the longevity of parts exposed to humid or saline environments.

As the aerospace industry continues its trajectory toward faster, lighter, and more innovative aircraft and spacecraft, the role of high-performance components will only become more critical. Custom aluminum enclosure CNC machining services are at the very heart of this evolution. It is a discipline that goes beyond simply cutting metal; it is about engineering the future of flight, one precisely crafted component at a time, ensuring that each part contributes to systems that are safer, more efficient, and more reliable than ever before.

At SOMI Custom Parts, we are an advanced manufacturing partner dedicated to delivering cutting-edge CNC machining solutions that meet the aerospace sector's most rigorous demands. Our deep expertise in aluminum enclosure CNC machining, combined with an unwavering commitment to precision, quality, and compliance, allows us to produce components that excel in the most challenging conditions imaginable. We invite you to contact us to discover how our specialized CNC machining services can help elevate your next aerospace project to new heights.