3D Printing vs. Injection Molding: A Comparative Guide from a Plastic Injection Molding Service Provider

- Share

- Issue Time

- Dec 24,2025

Summary

This comparative guide from a plastic injection molding service provider contrasts 3D printing and injection molding. It covers processes, advantages (prototyping flexibility vs high-volume efficiency), cost/volume break-even, material options, design rules, applications, and hybrid strategies for optimal product development in industries like medical, automotive, and consumer goods.

As a Plastic Injection Molding Service Provider, we understand that choosing the right manufacturing method for your plastic parts is crucial. Two primary techniques, 3D printing and injection molding, offer distinct advantages depending on your project's specific needs. Both 3D printing and injection molding are techniques for producing plastic parts, but they each have unique benefits.

This guide will explore the nuances of 3D printing and injection molding, helping you determine which process, or combination of processes, is best suited for your manufacturing goals. We'll delve into the strengths and weaknesses of each from the perspective of a Plastic Injection Molding Service Provider. The decision between them often comes down to factors like production volume, design complexity, cost, and lead time.

Understanding the Fundamentals: 3D Printing vs. Plastic Injection Molding Service Provider Insights

To make an informed decision, it's essential to first grasp the core principles of each technology. While both create physical objects, their approach is fundamentally different. One builds an object from the ground up, layer by layer, while the other forms it in a single, high-pressure action.

What is 3D Printing?

3D printing, also known as additive manufacturing, is a process that builds three-dimensional objects from a digital file. The process works by adding material layer by layer until the object is complete. Think of it like a high-tech hot glue gun, precisely controlled by a computer, that draws an object in three dimensions, one thin slice at a time. This method is the direct opposite of traditional subtractive manufacturing, where a part is created by cutting away material from a solid block.

The process begins with a computer-aided design (CAD) model, which is a digital blueprint of the final part. This model is then "sliced" into hundreds or thousands of thin, horizontal layers. A 3D printer reads this sliced file and begins to deposit, fuse, or solidify material—such as plastic, resin, or metal powder—layer by layer to construct the physical object.

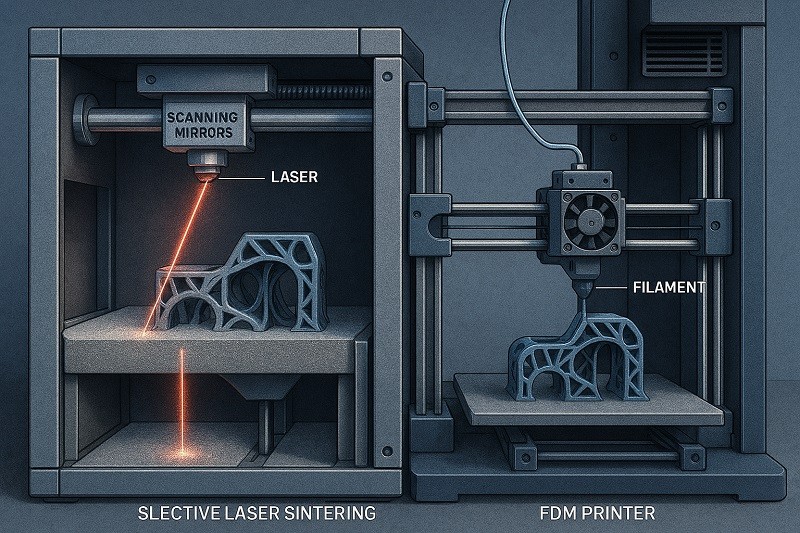

There are many types of 3D printing technologies, each with its own method and materials. Some of the most common include:

- Fused Deposition Modeling (FDM): This is the most widely accessible form of 3D printing. It works by extruding a thin filament of thermoplastic material, like ABS or PLA, through a heated nozzle to build the object layer by layer.

- Stereolithography (SLA): This process uses an ultraviolet (UV) laser to cure a liquid photopolymer resin in a vat, hardening it layer by layer to form a solid object.

- Selective Laser Sintering (SLS): SLS uses a high-powered laser to fuse small particles of polymer powder together.

- Multi Jet Fusion (MJF): This technology applies a fusing agent to a bed of polymer powder and then uses infrared energy to fuse the material into a solid layer.

Rapid Prototyping and Design Flexibility

One of the greatest advantages of 3D printing is its role in rapid prototyping. Additive manufacturing allows designers and engineers to create physical models and functional prototypes quickly and affordably. This ability to bring a concept to life in a matter of hours or days provides an invaluable opportunity to test a design's form, fit, and function before committing to expensive production tooling. If a design flaw is found, engineers can simply adjust the CAD file and print a new iteration, a process that is far more efficient and cost-effective than modifying traditional molds.

Furthermore, 3D printing offers unparalleled design freedom. Since the part is built from the ground up, designers can create incredibly complex geometries, intricate internal lattices, and organic shapes that would be impossible or prohibitively expensive to produce with traditional methods. This capability allows for part consolidation, where multiple components of an assembly can be redesigned and printed as a single, more efficient part, often reducing weight without sacrificing strength.

Low Upfront Costs and On-Demand Production

For small production runs, custom parts, or initial prototypes, 3D printing is exceptionally cost-effective. Unlike injection molding, it requires no tooling, which means the significant upfront investment in creating a mold is completely eliminated. The cost of a 3D printed part is primarily determined by the amount of material used, the machine time, and any necessary labor for post-processing. This makes it economically viable to produce a single part or a small batch of just a few hundred units.

This leads to the benefit of on-demand production. Because there are no tooling costs to amortize, companies can print parts as they are needed, reducing the need for large inventories and storage space. This "print-on-demand" model is ideal for creating custom jigs, fixtures, and tools for the manufacturing floor, or for producing highly personalized consumer products. Services exist that allow you to simply upload a file and receive a price quote instantly, with no minimum order quantity.

Limitations in Speed and Material Options

Despite its advantages, 3D printing has its limitations, particularly when scaling to mass production. The primary drawback is speed. While printing a single prototype is fast, the layer-by-layer process means that producing thousands of parts can take a very long time, as the print time per part remains relatively constant regardless of quantity. For example, printing ten parts takes roughly ten times as long as printing one. This makes it less competitive for high-volume runs where other methods can produce parts in seconds.

Another limitation is material selection. While the range of 3D printing materials is constantly expanding, it is still more limited compared to the vast library of thermoplastics available for injection molding. Many common 3D printing materials, especially for affordable FDM printers, may not have the required mechanical strength, heat resistance, or chemical resistance for demanding end-use applications. Furthermore, the layer-by-layer construction can result in parts that are anisotropic, meaning they are weaker in one direction (along the Z-axis) compared to others. Finally, many 3D printing processes result in a rougher surface finish with visible layer lines, often requiring additional post-processing steps like sanding or vapor smoothing to achieve a polished look.

What is Plastic Injection Molding, According to a Plastic Injection Molding Service Provider?

Plastic injection molding is a highly efficient manufacturing process designed for producing large quantities of identical plastic parts. It is the undisputed workhorse of the modern manufacturing world, responsible for creating a vast array of the plastic items we use every day, from automotive components and medical devices to consumer electronics and packaging.

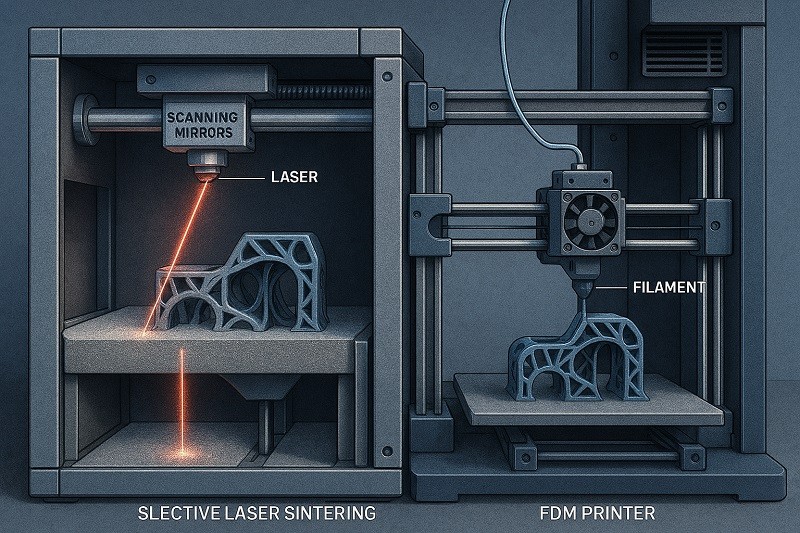

The process itself is conceptually straightforward but requires precision engineering. It involves several key steps:

- Clamping: An injection molding machine, which consists of a clamping unit and an injection unit, first closes and securely clamps together the two halves of a custom-made mold. These molds, also known as tools or dies, are typically machined from steel or aluminum.

- Injection: Raw plastic material, usually in the form of small pellets or granules, is fed from a hopper into a heated barrel. Inside the barrel, a reciprocating screw melts the plastic and forces it forward. This molten plastic is then injected under extremely high pressure into the mold cavity.

- Cooling: Once the mold cavity is filled, the molten plastic begins to cool and solidify, taking the shape of the mold. The mold is designed with internal cooling channels to control and expedite this process.

- Ejection: After the part has cooled sufficiently, the mold opens, and the solidified part is pushed out by ejector pins. The machine is then ready to begin the next cycle.

This entire cycle can take anywhere from a few seconds to a couple of minutes, depending on the part's size and complexity, allowing for immense production output.

High-Volume Efficiency and Consistent Quality

The primary advantage of plastic injection molding is its incredible efficiency and speed in high-volume production. Once the mold is created and the machine is set up, parts can be produced at an extremely rapid rate, with cycle times often measured in seconds. This makes it the most cost-effective method for manufacturing parts in the thousands or millions. As production volume increases, the initial cost of the mold is spread across more units, dramatically lowering the cost per part.

Furthermore, the process is highly automated and repeatable. This ensures exceptional consistency from one part to the next, even across massive production runs. By using the same precision-machined mold for every cycle, injection molding can achieve very tight tolerances, ensuring that every part is virtually identical. This consistency is critical for applications where parts must fit together perfectly, such as in electronics or automotive assemblies.

Superior Mechanical Properties and Surface Finish

Injection molded parts generally exhibit superior strength and mechanical properties compared to their 3D printed counterparts. Because the part is formed from a single mass of molten plastic that solidifies under pressure, it results in a solid, dense object with excellent structural integrity. This process minimizes the potential for weak points, unlike the layer-by-layer method of 3D printing which can create anisotropy. Modern engineered plastics used in injection molding can be incredibly strong and durable, sometimes even rivaling metal parts in certain applications.

Another significant benefit is the ability to achieve a wide range of high-quality surface finishes directly from the mold. The finish of the mold cavity is directly transferred to the plastic part. This means that parts can be produced with surfaces ranging from a highly polished, glossy "diamond finish" to various textured or matte finishes. Textures can be used not only for aesthetic purposes, hiding imperfections like fingerprints, but also for functional reasons, such as improving grip or paint adhesion.

Higher Initial Tooling Costs and Longer Lead Times

The most significant drawback of injection molding is the high upfront cost and long lead time associated with creating the mold. A production-quality mold is a complex piece of precision engineering, typically machined from hardened steel to withstand the high pressures and temperatures of the molding process. The cost of designing and fabricating such a tool can range from several thousand dollars for a simple, single-cavity mold to over $100,000 for a complex, multi-cavity mold designed for high-volume production.

This tooling process is also time-consuming. The lead time to manufacture a production-ready mold can be anywhere from a few week to several months, depending on its complexity. This includes time for design, machining, polishing, and testing. This initial investment in time and money means that injection molding is generally not suitable for prototyping or very low-volume production runs, as the cost per part would be prohibitively high.

Key Considerations When Choosing Your Manufacturing Partner: A Plastic Injection Molding Service Provider's Perspective

Choosing between 3D printing and injection molding is not just a technical decision; it's a strategic one that will impact your product's cost, quality, and time-to-market. As an experienced plastic injection molding service provider, we guide clients through this decision-making process daily. The optimal choice depends on a careful evaluation of several interconnected factors.

Production Volume and Capacity: What Your Plastic Injection Molding Service Provider Needs to Know

The most critical factor influencing the choice between these two technologies is the required production volume. This is where the economic models of 3D printing and injection molding diverge most significantly.

Low to Medium Volume (10,000 units or less)

For prototypes, custom parts, and low-volume production runs, 3D printing is often the more economical choice. The primary reason is the absence of tooling costs. Since parts are printed directly from a CAD file, there is no need to invest thousands of dollars in a mold. This makes 3D printing ideal for producing quantities from a single piece up to several hundred. For volumes in the low thousands, it can still be a viable option, especially if design flexibility or speed is a priority. This approach is often used for "bridge production," where 3D printed parts are used to get a product to market while the high-volume injection molds are being manufactured.

Additive manufacturing excels in low-volume scenarios by offering:

- Cost-Effectiveness: No tooling investment means startup costs are minimal. This is highly beneficial for startups and for testing new products.

- On-Demand Production: Parts can be printed as needed, reducing inventory costs and waste.

- Customization: It's easy to produce a wide variety of different parts in the same production batch without any added tooling cost.

High Volume (over 10,000 units)

When a part needs to be produced in quantities of 10,000 units or more, injection molding becomes the undisputed champion of cost-efficiency. Although the initial investment in a steel mold is high, the cost is amortized over the large number of parts produced. This dramatically lowers the cost per part to a level that 3D printing cannot match. The high speed of injection molding, with cycle times often measured in seconds, means that production is incredibly fast and efficient at scale. The crossover point where injection molding becomes cheaper than 3D printing typically falls somewhere between 1,000 and 10,000 units, depending heavily on the part's complexity and material. For mass production, the scalability and low per-piece price of injection molding are unparalleled.

Cost Comparison: 3D Printing vs. Injection Molding

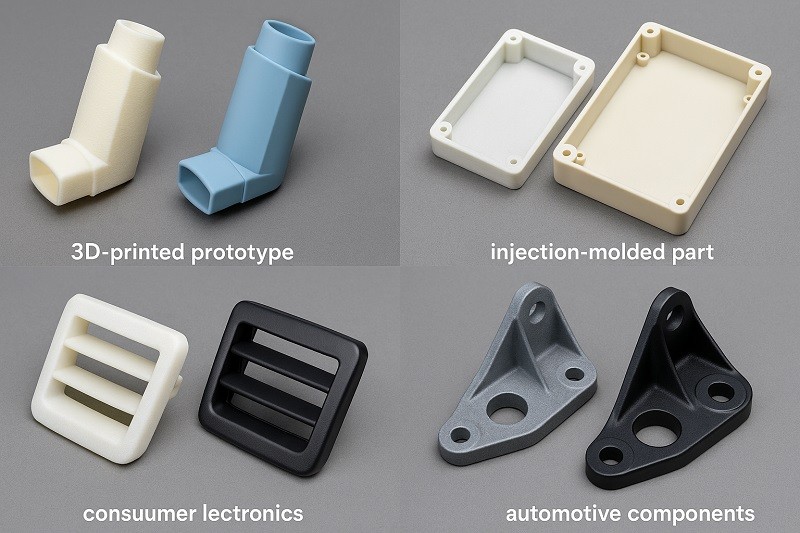

| Feature | 3D Printing | Injection Molding |

|---|---|---|

| Tooling Cost | $0 | $5,000 - $100,000+ |

| Cost per Part (Low Volume) | Low | Very High |

| Cost per Part (High Volume) | Remains High | Very Low |

| Optimal Volume | 1 - 10,000 units | 10,000+ units |

| Lead Time | Days | Weeks to Months |

Part Complexity and Design: Guidance from Your Plastic Injection Molding Service Provider

The geometry of your part plays a significant role in determining which manufacturing process is more suitable. Each method has its own set of design rules and constraints.

Intricate Geometries and Internal Structures

3D printing offers almost limitless design freedom. Because it builds objects layer by layer, it can create incredibly complex and intricate shapes, such as internal lattices, organic curves, and enclosed cavities, often at no additional manufacturing cost. This capability is a significant advantage for applications requiring lightweighting, part consolidation, or designs that are simply impossible to mold. Additive manufacturing allows designers to think purely about the part's function without being overly constrained by traditional manufacturing limitations.

Draft Angles and Undercuts

Injection molding, by contrast, has more stringent design rules dictated by the need to eject the part from the mold. This is known as Design for Manufacturability (DFM). Two key DFM principles are draft angles and undercuts.

- Draft Angles: These are slight tapers applied to the vertical walls of a part. Even a small draft angle (typically 1-2 degrees) is crucial to allow the part to release cleanly from the mold during ejection. Without a draft, the part can drag against the mold surface, causing scratches, or it may get stuck entirely, damaging the part and potentially the mold. The required draft angle increases with textured surfaces.

- Undercuts: An undercut is a feature that prevents the part from being ejected in a straight line from the mold. Examples include side holes or locking tabs. These features can be molded, but they require the use of complex and expensive mold mechanisms like side-actions or lifters, which can significantly increase the tooling cost.

An experienced plastic injection molding service provider will perform a DFM analysis on your design to identify and resolve these issues before the expensive tooling is created, saving time and money.

Lead Time and Cost Implications for a Plastic Injection Molding Service Provider

Your project timeline and budget are intrinsically linked to your choice of manufacturing process. The trade-offs between speed and cost are stark.

Rapid Turnaround for 3D Printing

If you need parts in your hands quickly, 3D printing is the clear winner. From a final CAD file, physical parts can be produced and shipped in a matter of days. This speed is a game-changer for rapid prototyping, allowing for multiple design iterations in a short period. The lead time for 3D printing is significantly shorter because it completely bypasses the time-consuming step of mold fabrication.

Investing in Injection Molding Tooling for Long-Term Savings

Injection molding involves a much longer initial lead time due to the need to design, manufacture, and test a custom mold. This process can take anywhere from several weeks to several months. However, this initial investment in time and capital pays off in the long run for high-volume projects. Once the mold is complete, the production of parts is extremely fast, and the per-part cost is very low. The high cost of the mold is an investment that unlocks significant economies of scale, making injection molding the most affordable method for mass production.

The Power of Customization: How a Plastic Injection Molding Service Provider Can Elevate Your Product

While often viewed as a process for mass production, injection molding offers a surprising degree of customization that can significantly enhance a product's performance, aesthetics, and overall value. A knowledgeable plastic injection molding service provider acts as a key partner in this process, leveraging deep expertise in materials and tooling to transform a standard part into a highly optimized, custom component. This collaboration ensures that the final product not only meets but exceeds the specific demands of its application.

Endless Possibilities with Custom Molded Parts

The core of injection molding customization lies in the mold itself. Since the mold is custom-built for each project, it can be designed to create parts with a wide range of specific features. This goes far beyond simple shapes, enabling the production of components with intricate details, integrated functions, and unique forms tailored to a precise need. Custom plastic parts are essential in countless industries, from specific housings for medical devices to lightweight, durable components for military and aerospace applications.

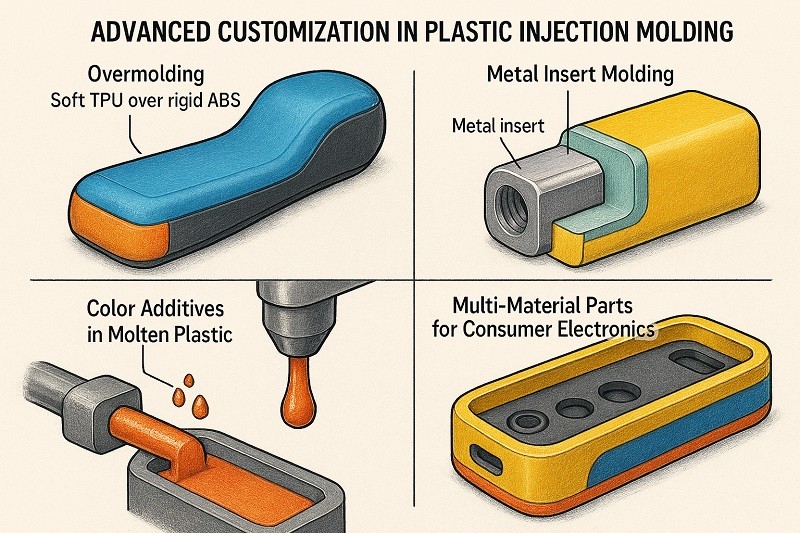

This process allows for the integration of features that would otherwise require secondary assembly steps, saving time and money. Examples include molding threaded inserts directly into a part for robust fastening points, or creating living hinges—thin sections of plastic that act as a hinge—for container lids. Furthermore, processes like overmolding and insert molding open up another level of customization.

- Overmolding: This process molds a soft, rubber-like material (like TPE) over a rigid plastic substrate. It's commonly used to add ergonomic grips to tool handles or create seals on electronic enclosures.

- Insert Molding: This involves placing a pre-formed component (often metal, such as a brass threaded insert or an electrical connector) into the mold before injecting the plastic, which then flows around the insert to create a single, integrated part.

An experienced service provider can help design these features effectively, ensuring they add value without unnecessarily complicating the molding process.

Enhanced Performance through Material Expertise from a Plastic Injection Molding Service Provider

The choice of plastic resin is one of the most critical decisions in creating a custom part. With thousands of polymers available, each with a unique profile of properties, selecting the right one is essential for ensuring the part performs correctly in its intended environment. A seasoned plastic injection molding service provider offers invaluable material expertise to navigate this complex selection process.

Selecting the Right Polymer Resins

Plastics are generally divided into two main categories: amorphous and semi-crystalline.

- Amorphous plastics (e.g., ABS, Polycarbonate, Polystyrene) are known for their excellent dimensional stability, good impact strength, and natural transparency. They soften over a wide range of temperatures, which can make processing easier.

- Semi-crystalline plastics (e.g., Nylon, Polypropylene, PEEK) offer superior chemical resistance, wear resistance, and flexibility. Their ordered molecular structure gives them strength and rigidity.

Beyond these broad categories, resins are further classified as commodity, engineering, or high-performance plastics.

- Commodity Resins like Polypropylene (PP) and Polyethylene (PE) are inexpensive and used for everyday items like packaging and containers.

- Engineering Resins such as Acrylonitrile Butadiene Styrene (ABS), Polycarbonate (PC), and Nylon (PA) offer a better balance of mechanical strength and thermal resistance for more demanding applications.

- High-Performance Resins like PEEK and PEI (Ultem®) provide exceptional strength and resistance to extreme heat and chemicals, making them suitable for critical applications in aerospace, medical, and automotive industries.

The right choice depends on a thorough analysis of the part's requirements, including mechanical load, chemical exposure, operating temperature, and regulatory compliance (e.g., FDA standards for food contact).

Additives for Specialized Properties

To further customize performance, a wide variety of additives can be compounded with the base polymer. These substances are mixed with the plastic pellets before molding to enhance or modify the material's properties. Without these additives, many plastics would not be able to perform in their intended applications.

Common additives include:

- Reinforcing Fillers: Glass or carbon fibers are added to increase strength, stiffness, and dimensional stability.

- Colorants and Pigments: Used to achieve specific colors and aesthetic effects that are consistent throughout the part.

- UV Stabilizers: Protect the plastic from degrading when exposed to sunlight, preventing it from becoming brittle or discolored.

- Flame Retardants: Added to meet safety standards by reducing the flammability of the plastic, which is critical for electronics and building materials.

- Plasticizers: Increase flexibility and reduce the brittleness of rigid plastics.

- Antistatic Agents: Reduce the buildup of static electricity on the surface of the part, which is important for electronic component packaging.

By working with a service provider, you can select the perfect combination of resin and additives to create a custom material compound tailored precisely to your needs.

Precision and Accuracy for Critical Applications: A Focus on Quality from Your Plastic Injection Molding Service Provider

For many industries, including medical, aerospace, and electronics, precision is not a luxury—it's a necessity. High-precision injection molding is a specialized process capable of producing parts with extremely tight tolerances, often as fine as ±0.025 mm or even tighter. Achieving this level of accuracy is a testament to a manufacturer's expertise and control over every variable in the process.

This process requires:

- High-Precision Molds: The mold itself must be manufactured to exceptionally high standards, using advanced CNC machining and EDM processes. The alignment between the mold's core and cavity is critical.

- Advanced Process Control: The injection molding machine's parameters—including injection pressure, temperature, cooling rate, and cycle time—must be meticulously controlled and monitored in real-time. This often involves the use of scientific molding principles to optimize the process for consistency.

- Material Stability: Choosing a material with a low and predictable shrink rate, such as an amorphous polymer like PC or a stable engineering resin like POM, is crucial for maintaining tight tolerances.

- Rigorous Quality Control: Finished parts are verified using advanced metrology equipment like coordinate measuring machines (CMMs) and optical scanners to ensure they meet the specified dimensions. Statistical Process Control (SPC) is used to monitor production trends and prevent defects before they occur.

When parts must fit and function perfectly every time, partnering with a plastic injection molding service provider who specializes in high-precision molding is essential to guarantee the reliability and performance of your final product.

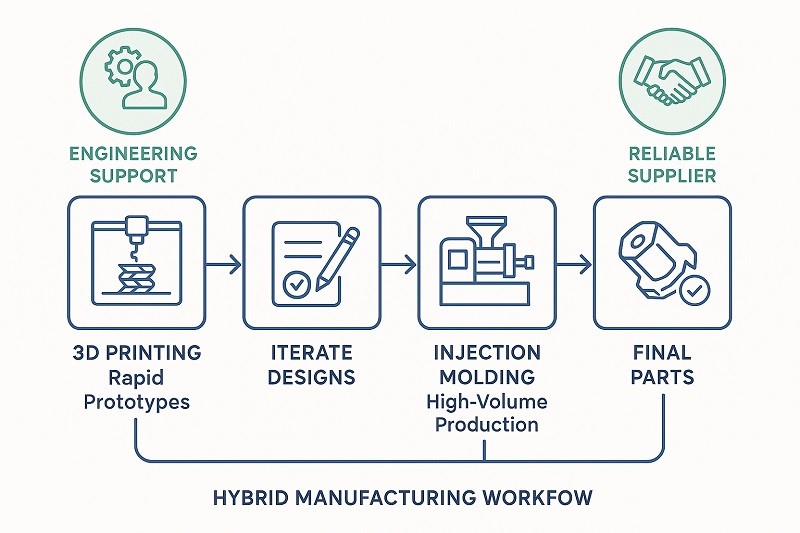

The Synergistic Approach: Combining 3D Printing and Plastic Injection Molding with Your Service Provider

The debate between 3D printing and injection molding is often framed as an "either/or" choice. However, the most innovative and efficient manufacturing strategies often involve a synergistic approach that leverages the strengths of both technologies. By viewing them as complementary rather than competing processes, you can significantly optimize your product development cycle, reduce risks, and accelerate your time to market. A forward-thinking service provider can help architect a hybrid workflow that harnesses the best of both worlds.

Accelerating Product Development with 3D Printed Prototypes and Tooling

The most common and powerful synergy between these two technologies is using 3D printing for rapid prototyping before committing to expensive and time-consuming injection mold tooling. The speed and low cost of 3D printing allow designers and engineers to create multiple physical iterations of a part in a matter of days. This rapid feedback loop is invaluable for:

- Design Validation: Holding a physical part allows teams to test its form, fit, and ergonomics.

- Functional Testing: Prototypes made from engineering-grade 3D printing materials can be used to test a part's mechanical function, allowing for the discovery and correction of design flaws early in the process.

- Stakeholder Feedback: Physical models are much more effective than digital renderings for gathering feedback from customers, marketing teams, and other stakeholders.

By thoroughly vetting a design with 3D-printed prototypes, companies can enter the injection molding phase with high confidence that the design is sound, significantly reducing the risk of costly mold modifications.

Beyond prototyping, 3D printing is also revolutionizing the creation of the tooling itself. It is now possible to 3D print molds (or mold inserts) from high-temperature resins. While these plastic molds don't have the lifespan of steel tooling, they are perfect for short-run injection molding. This allows for the production of a few hundred parts in the final production material—ideal for pilot runs, market testing, or bridge manufacturing—at a fraction of the cost and time of traditional mold making.

Optimizing Production Workflow: A Strategy Our Plastic Injection Molding Service Provider Recommends

An optimized manufacturing workflow seamlessly integrates 3D printing and injection molding at different stages of the product lifecycle. This structured, hybrid approach maximizes efficiency, minimizes costs, and maintains agility.

A typical optimized workflow looks like this:

- Concept & Design: A part is designed using CAD software.

- Rapid Prototyping (3D Printing): The design is 3D printed, often multiple times with quick iterations, to validate the form, fit, and basic function. This stage can take just a few days.

- Bridge Tooling / Low-Volume Production (3D-Printed Molds): For early market testing or to fulfill initial orders, a 3D-printed mold is created. This allows for the injection molding of several hundred parts in the actual end-use plastic. This step bridges the gap between prototyping and mass production.

- Mass Production (Steel Molds): Once the design is finalized and market-validated, a traditional steel injection mold is manufactured for high-volume production. The knowledge gained from the 3D-printed mold can inform and de-risk the creation of this final, expensive tool.

- Lifecycle Support (3D Printing): If a spare part is needed years later after the main production has ceased, it can be produced on-demand using 3D printing, eliminating the need for storing old molds or inventory.

This strategic workflow leverages 3D printing for its speed and flexibility at the beginning of the product lifecycle and injection molding for its cost-effectiveness and scalability for mass production. Adopting strategies like design automation and process analysis can further enhance the efficiency of this workflow.

Industry-Specific Applications: From Medical Devices to Consumer Goods

The synergistic use of 3D printing and injection molding is creating value across numerous industries.

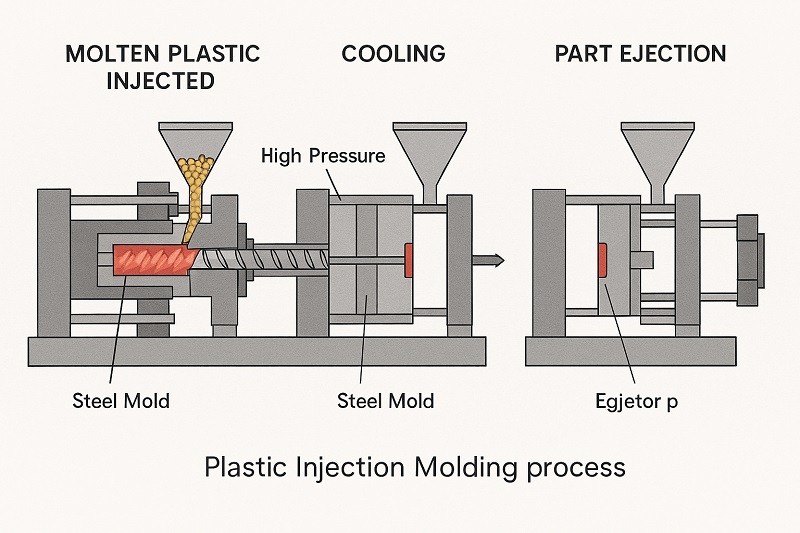

- Medical and Dental: This sector heavily relies on both technologies. 3D printing is used to create patient-specific surgical guides, anatomical models for planning complex surgeries, and custom prosthetics. For high-volume disposable devices like syringes or mass-produced diagnostic components, injection molding is the standard. A hybrid approach is often used where 3D-printed molds create prototypes of new medical devices in medical-grade silicone or other biocompatible materials before scaling to mass production with traditional tooling.

Consumer Goods: The consumer electronics and goods industry benefits greatly from accelerated development cycles. Companies 3D print numerous iterations of product enclosures, like phone cases or remote controls, to perfect the ergonomics and aesthetics. Once the design is locked in, injection molding takes over to produce millions of units at a low cost. For highly customized products, like personalized eyewear or bespoke furniture components, 3D printing is sometimes used for final production, offering a level of customization that injection molding cannot match.

Automotive and Aerospace: In these industries, 3D printing is used to prototype complex parts like air ducts and interior components. It is also employed to create custom jigs, fixtures, and tools for the assembly line, improving manufacturing efficiency. For the production of the millions of plastic clips, housings, and interior trim pieces that go into every vehicle, injection molding is the only viable method due to its speed and cost-effectiveness. The combination allows for rapid innovation in design followed by scalable, cost-effective mass production.

By understanding how these technologies can work in tandem, a skilled plastic injection molding service provider can help you create a more resilient, efficient, and innovative manufacturing strategy.

Selecting the Right Plastic Injection Molding Service Provider: What to Look For

Choosing a manufacturing partner is a critical decision that extends far beyond simply finding the lowest price. A true partner becomes an extension of your team, providing the expertise and support needed to turn your concept into a successful product. As an experienced Plastic Injection Molding Service Provider, we understand that our value lies not just in our machines, but in our people, processes, and commitment to your success. Here’s what you should look for when selecting your manufacturing provider.

Technical Capabilities and Range of Services

The first step is to ensure the provider has the right tools for the job. Not all molders are created equal; their capabilities can vary significantly.

Key technical aspects to evaluate include:

- Machine Tonnage and Variety: Does the provider have a wide range of press sizes (measured in tonnage)? This determines the size and type of parts they can produce. A provider with diverse machinery can handle a wider variety of projects and scale with you as your needs evolve.

- Specialized Molding Processes: Inquire about their experience with more advanced techniques. Do they offer services like insert molding, overmolding, or gas-assist molding? These capabilities can open up new design possibilities and reduce assembly costs.

- In-House Tooling: A provider that designs and builds molds in-house has greater control over quality and lead times. This integration streamlines the process and simplifies communication if mold adjustments are needed.

- Secondary and Value-Added Services: Manufacturing often doesn't end when the part is ejected from the mold. Look for a one-stop-shop that offers a full suite of secondary services, such as:

- Post-mold assembly

- Sonic welding or heat staking

- Pad printing or laser engraving

- Custom packaging A partner who can manage the entire process from molding to final assembly can save you significant time and logistical headaches.

Design and Engineering Support: A Critical Offering from Your Plastic Injection Molding Service Provider

One of the most valuable services a top-tier injection molding provider can offer is comprehensive design and engineering support. An experienced engineering team can be the difference between a smooth product launch and a project plagued by costly delays and redesigns.

A crucial part of this is the Design for Manufacturability (DFM) analysis. A DFM review is a collaborative process where the provider's engineers analyze your part design to ensure it is optimized for the injection molding process. This analysis should be performed before any steel is cut for the mold, as this is the least expensive time to address issues.

A thorough DFM analysis will identify and offer solutions for potential problems such as:

- Inadequate draft angles that could cause ejection issues.

- Non-uniform wall thicknesses that can lead to sink marks or warping.

- Complex undercuts that would drive up tooling costs.

- Suboptimal gate locations that could create cosmetic defects or structural weak points.

- Material selections that may not be suitable for the part's application or design.

By collaborating with a provider who offers robust engineering support and DFM analysis, you can reduce tooling costs, shorten development time, and improve the overall quality and reliability of your final product.

Quality Assurance and Certifications: The Mark of a Reliable Plastic Injection Molding Service Provider

Quality should be at the core of everything your manufacturing partner does. A reliable provider will have a robust Quality Management System (QMS) in place to ensure consistency and precision from the first part to the last.

The most important indicator of a commitment to quality is ISO 9001 certification. This internationally recognized standard demonstrates that a company has established and follows a systematic approach to quality management, focused on customer satisfaction and continual improvement. An ISO 9001-certified company is audited regularly to ensure its processes are documented, controlled, and effective.

For specific industries, you may want to look for even more advanced certifications built upon the ISO 9001 framework, such as:

- ISO 13485: For the medical device industry.

- AS9100: For the aerospace and defense industry.

- IATF 16949: For the automotive industry.

Beyond certifications, ask about their quality control processes. Do they use tools like Coordinate Measuring Machines (CMMs) or optical gauging systems for part verification? Do they employ Statistical Process Control (SPC) to monitor and maintain consistency during production? A provider who is transparent about their quality systems is one you can trust.

Customer Service and Communication: Building a Strong Partnership with Your Plastic Injection Molding Service Provider

Ultimately, the relationship with your service provider is a partnership. Strong, clear, and consistent communication is the foundation of any successful manufacturing partnership. In a competitive market, excellent customer service can be a key differentiator.

When evaluating a potential provider, consider the following:

- Responsiveness: Do they respond to your inquiries and requests in a timely manner?

- Transparency: Are they open and honest about their processes, capabilities, and pricing?

- Collaborative Approach: Do they treat you like a partner, involving you in the decision-making process and working collaboratively to solve problems?

- Dedicated Support: Will you have a dedicated project manager or engineer as your single point of contact? This streamlines communication and ensures accountability.

- Long-Term Focus: Look for a provider who is interested in building a long-term relationship, not just completing a single transaction. A partner who understands your business and your products will be better equipped to anticipate your needs and contribute to your ongoing success.

Choosing the right plastic injection molding service provider is a strategic investment in your product's future. By carefully evaluating their technical capabilities, engineering support, quality systems, and commitment to customer service, you can build a strong partnership that delivers high-quality parts efficiently and cost-effectively.

Conclusion

Ultimately, the decision between 3D printing and injection molding, or a combination thereof, hinges on a thorough evaluation of your project's unique requirements. There is no single "best" method; the optimal choice is a strategic one, balancing the crucial factors of production volume, design complexity, material requirements, cost, and time-to-market. Partnering with an experienced Plastic Injection Molding Service Provider is key to navigating these choices effectively. The right partner does more than just manufacture parts—they provide the critical engineering expertise and strategic guidance needed to optimize your design and workflow for success.

At SOMI Custom Parts, we are a dedicated Plastic Injection Molding Service Provider and 3D printing service provider, offering expert Plastic Injection Molding solutions and 3D printing solutions to clients worldwide. We are committed to guiding you through every step of your manufacturing journey, ensuring optimal results for your plastic components. Whether you need the rapid flexibility of 3D printing for prototypes, the cost-effective scalability of injection molding for mass production, or a synergistic hybrid approach that leverages the best of both, our team is here to help you make the right choice. We encourage you to share this guide and contact us to discuss how we can bring your next project to life with precision, quality, and efficiency.